Detection system of automatic flexible checking tool based on contact measuring head

A detection system and contact technology, applied in measuring devices, instruments, electrical devices, etc., can solve the problems of high cost of non-contact probes, unfavorable promotion and use of small and medium-sized enterprises, etc. Shorten delivery time and quantify the effect of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

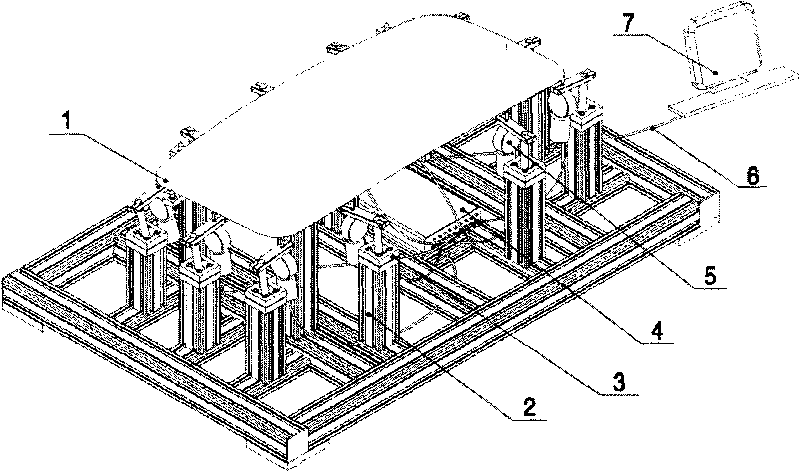

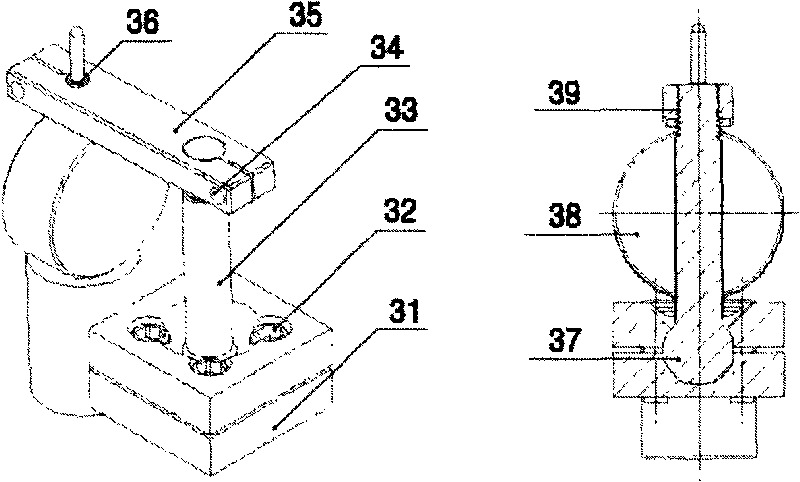

[0029] Embodiment one: typical multi-probe system (attached figure 1 )

[0030] A typical automatic flexible inspection system based on touch probes usually includes multiple touch probes with communication ports. The workpiece 1 to be tested is fixed on the adjustable tooling 2, and the touch probe 5 with communication ports is installed On the probe base 3 that can freely adjust the attitude of the probe, the probe base is fixed on the adjustable tooling through threaded connection, the communication port of the probe is connected to the input port of the controller 4 through a special communication cable, and the controller controls each probe according to the program. Manage with the external trigger signal and complete the measurement data acquisition. The measurement data is uploaded to the main control computer 7 through the connection cable 6 through the output port of the controller and stored in the designated database. The main control computer completes the statist...

Embodiment 2

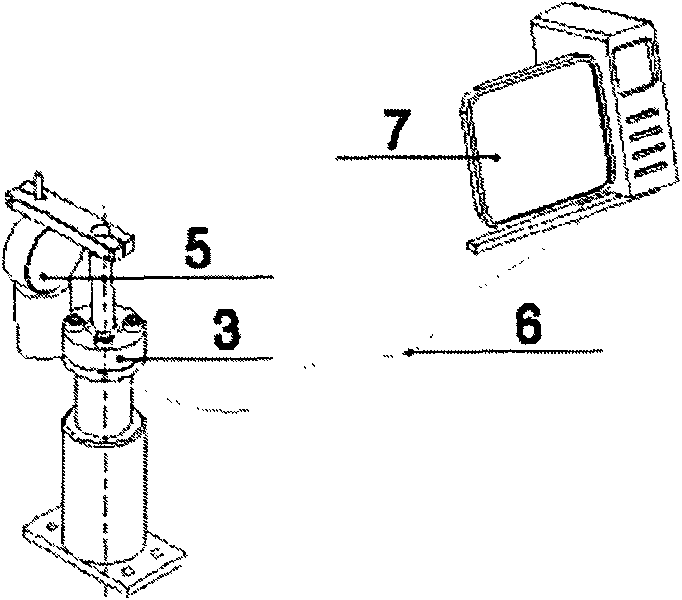

[0031] Embodiment 2: no controller system

[0032] When the system has only one or a few probes, the controller function can be integrated into the main control computer to form a controller-less system. Single-probe systems are usually simpler, such as image 3 As shown, it includes a probe base 3, a probe 5, a connecting cable 6 and a main control computer 7.

Embodiment 3

[0033] Embodiment 3: no master computer system

[0034] In the second embodiment, the main functions of the main control computer can also be integrated into a slightly expanded controller. For example, when the key input module and the display module are integrated into the controller, the system becomes a system without a main control computer. In addition to complex calculations and large database management, almost all main control computer functions can be completed in the controller. The display function of a typical hostless computer system can be completed by the controller's own liquid crystal display unit, such as Figure 4 As shown, it includes a probe base 3, a probe 5, a connecting cable 6, and an enhanced controller 4 with a display and key module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com