Water-based coating for surface of mechanical product

A water-based coating and mechanical product technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as the inability to meet the requirements of environmental protection and comprehensive performance, and achieve excellent artificial aging resistance, excellent adhesion, High hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

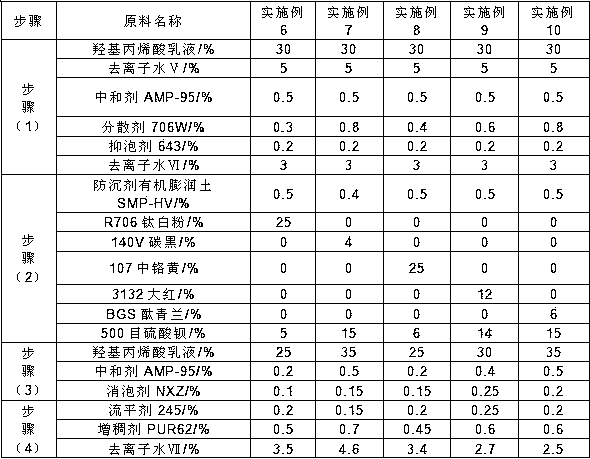

[0048] The preparation method of embodiment 1 water-based primer, comprises the steps:

[0049] Step (1): Dilute the uniformly mixed 10% epoxy ester emulsion A and 10% epoxy ester emulsion B with 10% deionized water I, and then add 0.5% neutralizer AMP-95 to adjust the pH value to 8.5-9.5, then add 0.3% drier HD-CG01, then add 0.2% dispersant 706W and 0.2% foam suppressor 643 diluted with 5% deionized water II while stirring, and stir The speed is 300 rpm, continue to stir to make it evenly mixed, and obtain the pre-emulsion;

[0050] Step (2): Add 10% of 190D iron oxide red, 10% of 500 mesh barium sulfate, 10% of 500 mesh heavy calcium and 0.6% of organic anti-settling agent to the pre-emulsion obtained in step (1). Bentonite SMP-HV was dispersed at 750 rpm for 10 minutes, and then ground with zirconium beads as the grinding medium until the fineness reached 40 microns to obtain the grinding slurry;

[0051] Step (3): Add 10% epoxy ester emulsion A to the grinding slurry ob...

Embodiment 2

[0055]The preparation method of embodiment 2 water-based primers, comprises the steps:

[0056] Step (1): Dilute the uniformly mixed 12% epoxy ester emulsion A and 10% epoxy ester emulsion B with 8% deionized water I, and then add 0.6% neutralizer AMP-95 to adjust the pH value to 8.5-9.5, then add 0.4% drier HD-CG01, then add 0.2% dispersant 706W and 0.2% foam suppressor 643 diluted with 4% deionized water II while stirring, and stir The speed is 300 rpm, continue to stir to make it evenly mixed, and obtain the pre-emulsion;

[0057] Step (2): Add 12% of 190D iron oxide red, 10% of 500 mesh barium sulfate, 7% of 500 mesh heavy calcium and 0.5% of organic anti-settling agent to the pre-emulsion obtained in step (1). Bentonite SMP-HV was dispersed at 850 rpm for 20 minutes, and then ground with zirconium beads as the grinding medium until the fineness reached 40 microns to obtain the grinding slurry;

[0058] Step (3): Add 10% epoxy ester emulsion A to the grinding slurry obta...

Embodiment 3

[0062] The preparation method of embodiment 3 water-based primers, comprises the steps:

[0063] Step (1): Dilute the uniformly mixed 10% epoxy ester emulsion A and 15% epoxy ester emulsion B with 5% deionized water I, and then add 0.65% neutralizer AMP-95 to adjust the pH value to 8.5-9.5, then add 0.4% drier HD-CG01, then add 0.2% dispersant 706W and 0.25% foam suppressor 643 diluted with 4% deionized water II while stirring, and stir The speed is 300 rpm, continue to stir to make it evenly mixed, and obtain the pre-emulsion;

[0064] Step (2): Add 13% of 190D iron oxide red, 7% of 500 mesh barium sulfate, 10% of 500 mesh heavy calcium and 0.45% of anti-sedimentation agent to the pre-emulsion obtained in step (1) while stirring Bentonite SMP-HV was dispersed at 800 rpm for 15 minutes, and then ground with zirconium beads as the grinding medium until the fineness reached 40 microns to obtain the grinding slurry;

[0065] Step (3): Add 10% epoxy ester emulsion A to the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com