Wrinkling and printing color paste as well as preparation method and application thereof

A technology of printing color paste and water-based pigment color paste, which is applied in the field of textile printing and dyeing, can solve the problems of energy consumption, and achieve the effects of saving space, bright colors, and strong wrinkle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

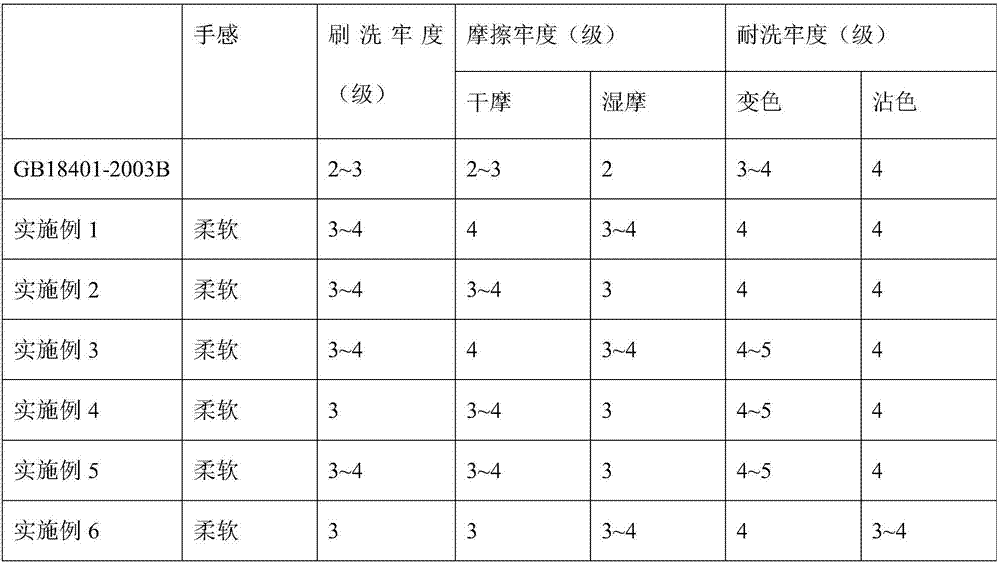

Examples

Embodiment 1

[0022] A preparation method for wrinkled printing paste, comprising the following steps:

[0023] The first step: Stir 20 parts of polyurethane acrylate, 40 parts of catechol, 1 part of emulsifier, and 30 parts of deionized water at 300r / min for 20min, and then ultrasonicate the mixture for 20min at an ultrasonic power of 700W. Aqueous polyurethane acrylate emulsion was obtained. Wherein, the emulsifier is a sulfosuccinate surfactant. In other embodiments, the phenolic substance may also be at least one of o-methoxyphenol, 2-methoxy-4-methylphenol, and 1,3-benzenediol. The emulsifier can also be at least one of sodium allyl ether hydroxysulfonate and fatty alcohol modified polyethylene glycol surfactant.

[0024] The second step: Weigh 5 parts of pigment, 4 parts of dispersant and 20 parts of deionized water, pre-disperse at room temperature at a speed of 7000r / min for 20 minutes, transfer to a circulating sand mill and grind for 1 hour, the speed of the sand mill 1000r / min...

Embodiment 2

[0028] A preparation method for wrinkled printing paste, comprising the following steps:

[0029] Step 1: Stir 40 parts of urethane acrylate, 20 parts of catechol, 2 parts of emulsifier, and 20 parts of deionized water at 300 r / min for 20 minutes, then ultrasonicate the mixture for 20 minutes at an ultrasonic power of 1000 W to obtain Waterborne polyurethane acrylate emulsion. Wherein, the emulsifier is a sulfosuccinate surfactant.

[0030] The second step: Weigh 6 parts of pigment, 8 parts of dispersant and 30 parts of deionized water, pre-disperse at room temperature at a speed of 8000r / min for 20 minutes, transfer to a circulating sand mill and grind for 2 hours, the speed of the sand mill 2000r / min to obtain water-based pigment paste. Wherein, the pigment is a yellow azo condensation dye. The dispersant is naphthalenesulfonate formaldehyde condensate.

[0031] Step 3: Mix 60 parts of urethane acrylate emulsion, 30 parts of water-based pigment paste, 3 parts of water-ba...

Embodiment 3

[0034] A preparation method for wrinkled printing paste, comprising the following steps:

[0035] The first step: Stir 20 parts of polyurethane acrylate, 20 parts of phenolic substances, 1 part of emulsifier, and 60 parts of deionized water at 700r / min for 20 minutes, and then ultrasonicate the mixture for 20 minutes at an ultrasonic power of 1000W to obtain water-based Polyurethane acrylate emulsion. Wherein, the emulsifier is a sulfosuccinate surfactant.

[0036] Step 2: Weigh 8 parts of pigment, 4 parts of dispersant and 25 parts of deionized water, pre-disperse at room temperature at a speed of 8000r / min for 20 minutes, transfer to a circulating sand mill and grind for 1 hour, the speed of sand mill 1500r / min to obtain water-based pigment paste. Wherein, the pigment is a yellow azo condensation dye. The dispersant is naphthalenesulfonate formaldehyde condensate.

[0037]Step 3: Mix 55 parts of urethane acrylate emulsion, 25 parts of water-based pigment paste, 2 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com