A kind of waterborne elastic polyurethane flame retardant coating and preparation method thereof

An elastic polyurethane and flame retardant coating technology, applied in the field of coatings, can solve the problems of difficult coating film surface spreading and leveling, poor anti-cracking and bending resistance, reducing fire extinguishing efficiency, etc., to improve rapid cooling and fire extinguishing. Good effect, good resistance to bending and protection, easy to spread and level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

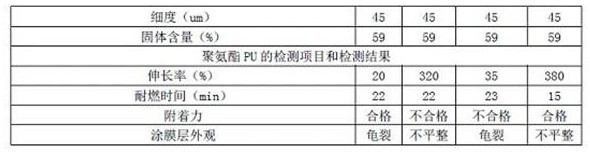

Image

Examples

preparation example Construction

[0049] Further, the present invention also proposes the preparation method of the above-mentioned waterborne elastic polyurethane flame retardant coating, comprising the following specific steps:

[0050] S1) Add water-based elastic polyurethane resin to pure water, stir and disperse with a disperser to obtain a resin dispersion;

[0051] S2) Add the dispersant to the resin dispersion, and stir well, then slowly add the pigment filler measured by the formula, stir and disperse to the specified fineness, and prepare the resin color paste;

[0052] S3) Adding the nitrogen-phosphorus flame retardant and the inorganic flame retardant according to the formula into the resin color paste, stirring and dispersing to a specified fineness, to prepare a flame retardant coating slurry;

[0053] S4) Add the thickener to the flame-retardant coating slurry to adjust the viscosity, stir evenly, and detect that the viscosity reaches a specified range, that is, the water-based elastic polyureth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com