Waterborne colored steel paint

A color steel, water-based technology, applied in the direction of coating, etc., can solve the problems of endangering human health, volatile, etc., and achieve the effect of good adhesion and smooth paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

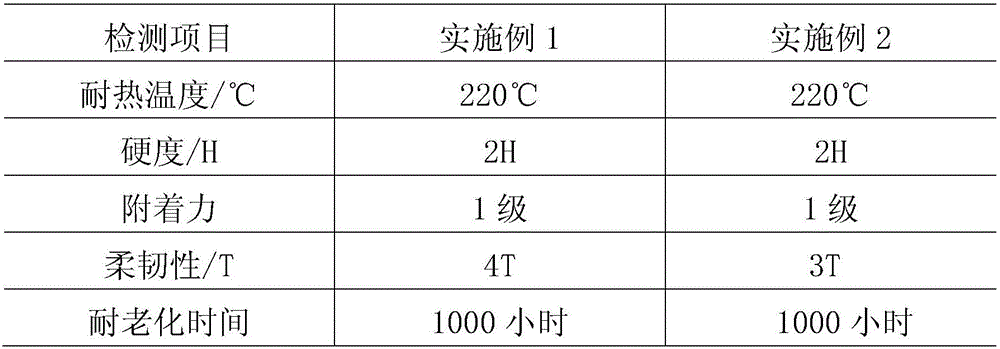

Examples

Embodiment 1

[0021] A kind of water-based color steel paint, is made up of the following raw materials of weight part:

[0022] 45 parts of water-based acrylic emulsion, 20 parts of silicone, 15 parts of titanium dioxide ZR-940, 11 parts of sericite powder, 2 parts of water-based color paste, 0.2 parts of ammonium salt dispersant 5040, 0.4 parts of non-ionic wetting agent PE-100, silicone oil 0.4 parts of defoaming agent, 0.5 parts of polyurethane leveling agent R2020, 0.5 parts of anti-sag agent BYK333, 5 parts of water.

[0023] The above-mentioned water-based color steel paint is developed by conventional application process, and the specific steps are as follows:

[0024] Pulping: first put water, ammonium salt dispersant, non-ionic wetting agent PE-100, silicone oil defoamer, leveling agent and anti-sagging agent into the dispersion tank, stir evenly, and mix titanium dioxide, silk Put mica powder in order, stir and disperse for 30-40 minutes until completely uniform; the dispersion ...

Embodiment 2

[0030] A kind of water-based color steel paint, is made up of the following raw materials of weight part:

[0031] 40 parts of water-based acrylic emulsion, 20 parts of silicone, 16 parts of titanium dioxide ZR-940, 13 parts of sericite powder, 2.5 parts of water-based color paste, 0.3 parts of ammonium salt dispersant 5040, 0.3 parts of non-ionic wetting agent PE-100, silicone oil 0.4 parts of defoaming agent, 0.7 parts of polyurethane leveling agent R2020, 0.8 parts of anti-sag agent BYK333, 6 parts of water.

[0032] The above-mentioned water-based color steel paint is developed by conventional application process, and the specific steps are as follows:

[0033] Pulping: first put water, ammonium salt dispersant, non-ionic wetting agent PE-100, silicone oil defoamer, leveling agent and anti-sagging agent into the dispersion tank, stir evenly, and mix titanium dioxide, silk Put mica powder in order, stir and disperse for 30-40 minutes until completely uniform; the dispersio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com