Apparatus and process for destructive distillation and cracking of biomass

A technology for cracking treatment and biomass, which is applied in the field of biomass dry distillation cracking treatment devices, which can solve the problems of imperfect process purpose and working condition target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

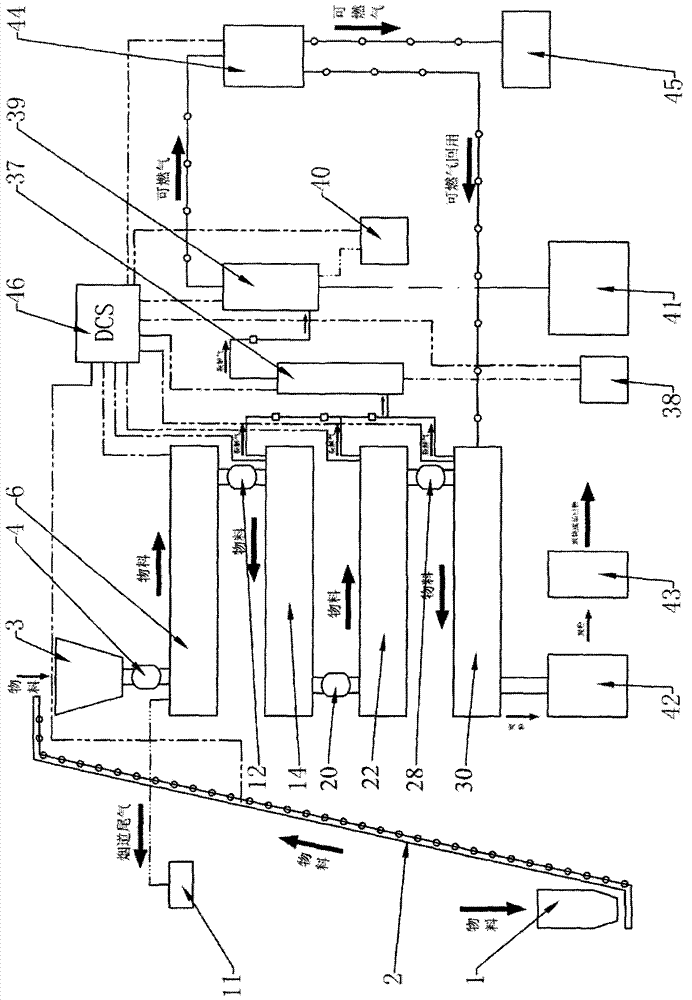

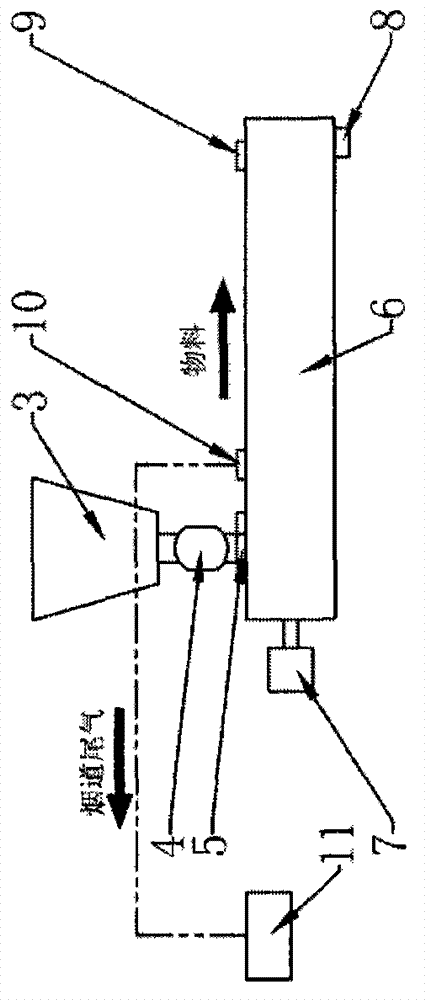

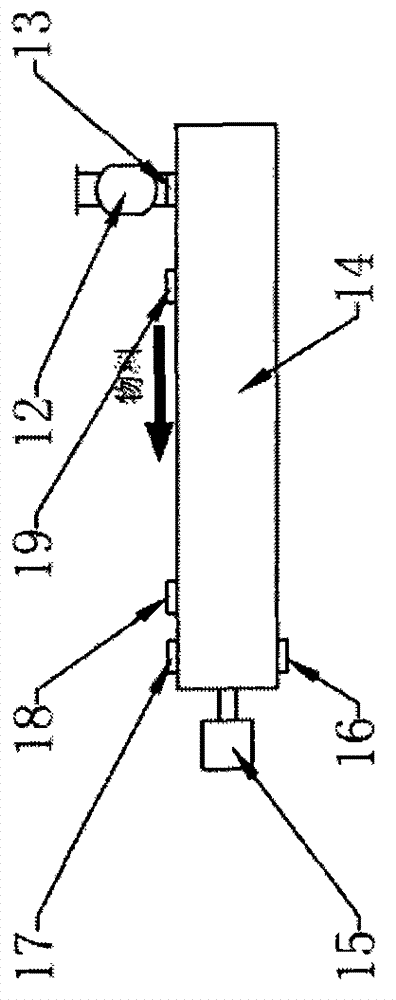

[0149] Below in conjunction with accompanying drawing and embodiment the present invention is further described as follows.

[0150] first to figure 1 A brief description of the connecting line in the middle, in which, the single line + 3 dots (that is, 3 dots) is the flue gas transmission pipeline; the single long line + 2 short lines is the DCS distributed control system; the single line A line + a single hollow box is a pyrolysis gas pipeline; a single line + a single hollow circle is a combustible gas pipeline; a single line + 1 point (that is, a dotted line) is a heavy oil carbon residue pipeline; a single line + The line connecting 2 points (namely 2 dotted line or double dotted line) is light oil pipeline; the line connecting single long drawn line + single point + 2 short drawn lines is sewage pipeline.

[0151] Such as figure 1 As shown, a biomass dry distillation cracking treatment device includes an input part, a reactor part, a control part and a processing outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com