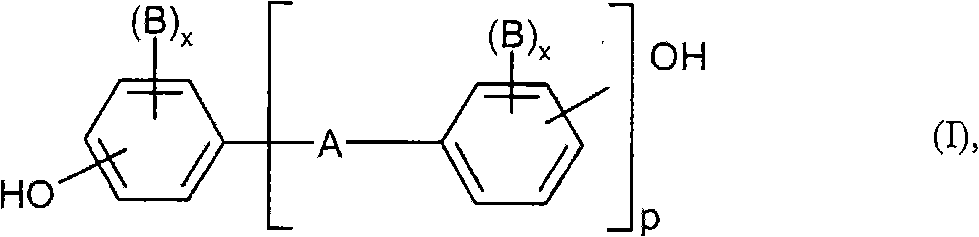

Blend of aromatic polycarbonate and polylactic acid, preparation method and application thereof

A technology of polycarbonate and blends, which is applied in the field of resins, can solve the problems of unfavorable processing, increase the melt viscosity of blends, increase the molecular weight of aromatic polycarbonate and polylactic acid, etc., and achieve improved compatibility and good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The method for preparing the blend of aromatic polycarbonate and polylactic acid provided by the present invention comprises the step of: blending the components a, b, and c to prepare the blend.

[0080] In the method, components d and e may also be included.

[0081] In the method, component f may be further included.

[0082] The ingredients can be combined and then melt blended to form a blend of polycarbonate and polylactic acid. The temperature of the melt blending is greater than or equal to the melting point of the component b, and less than the decomposition temperature of the component b; the temperature of the melt blending is determined by the ratio of aromatic polycarbonate and polylactic acid, aromatic polycarbonate The higher the content of polycarbonate, the higher the melting temperature; the temperature of the melt blending is preferably, but not limited to, 210-260°C; particularly preferably, 220-230°C.

[0083] The blend of polycarbonate and polyla...

Embodiment 1-6、 comparative Embodiment 1-5

[0097] Table 1 lists Examples 1-4 according to the present invention, and Comparative Examples C1-C3.

[0098] Table 2 lists Examples 5-6 according to the present invention, and Comparative Examples C4-C5.

[0099] Mix the following ingredients according to the data listed in Table 1 and Table 2:

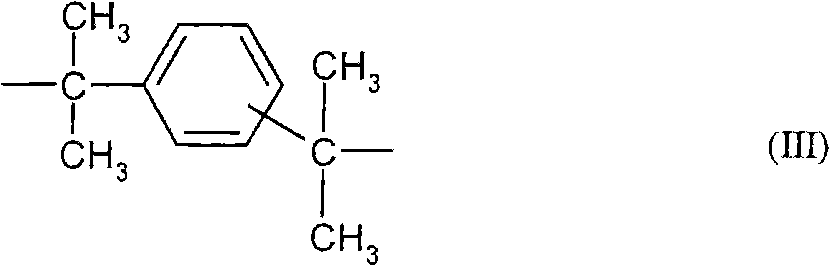

[0100] (a) bisphenol-A polycarbonate resin whose weight average molecular weight is 26,000, said weight average molecular weight is measured by GPC, converted according to polystyrene standard sample;

[0101] (b) polylactic acid with a weight-average molecular weight of 100,000, the weight-average molecular weight is measured by GPC and converted according to polystyrene standard samples;

[0102] (c) Tetrabutyl titanate with a purity of 99.5%.

[0103] Through a twin-screw extruder with a diameter of 25mm, under the conditions of a barrel temperature of 220°C and a rotational speed of 90rpm, the above-mentioned mixed components are melt-blended, and a strand-shaped molten line i...

Embodiment 7-11、 comparative Embodiment C6

[0120] Table 3 lists Examples 7-11 according to the present invention, and Comparative Example C6.

[0121] Premix the following ingredients according to the data listed in Table 3:

[0122] (a) a bisphenol-A polycarbonate resin with a weight-average molecular weight of 26,000, the weight-average molecular weight being converted to polystyrene;

[0123] (b) poly-L-lactic acid with a weight-average molecular weight of 100,000, the weight-average molecular weight being converted to polystyrene;

[0124] (c) tetrabutyl titanate with a purity of 99.5%,

[0125] (d) bisphenol A bis-(diphenyl phosphate) with a purity of 99%

[0126] (e) Polytetrafluoroethylene mixed powder.

[0127] Through a twin-screw extruder with a diameter of 25mm, under the conditions of a barrel temperature of 220°C and a rotational speed of 90rpm, the above-mentioned mixed components are melt-blended, and a strand-shaped molten line is drawn from the die, and cooled in the air , Obtain pellet resin mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com