Mechanical product assembly stand

A technology for mechanical products and assembly tables, applied in worktables, workpiece clamping devices, manufacturing tools, etc., can solve problems such as affecting production efficiency, inconvenient loading and unloading workpieces, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

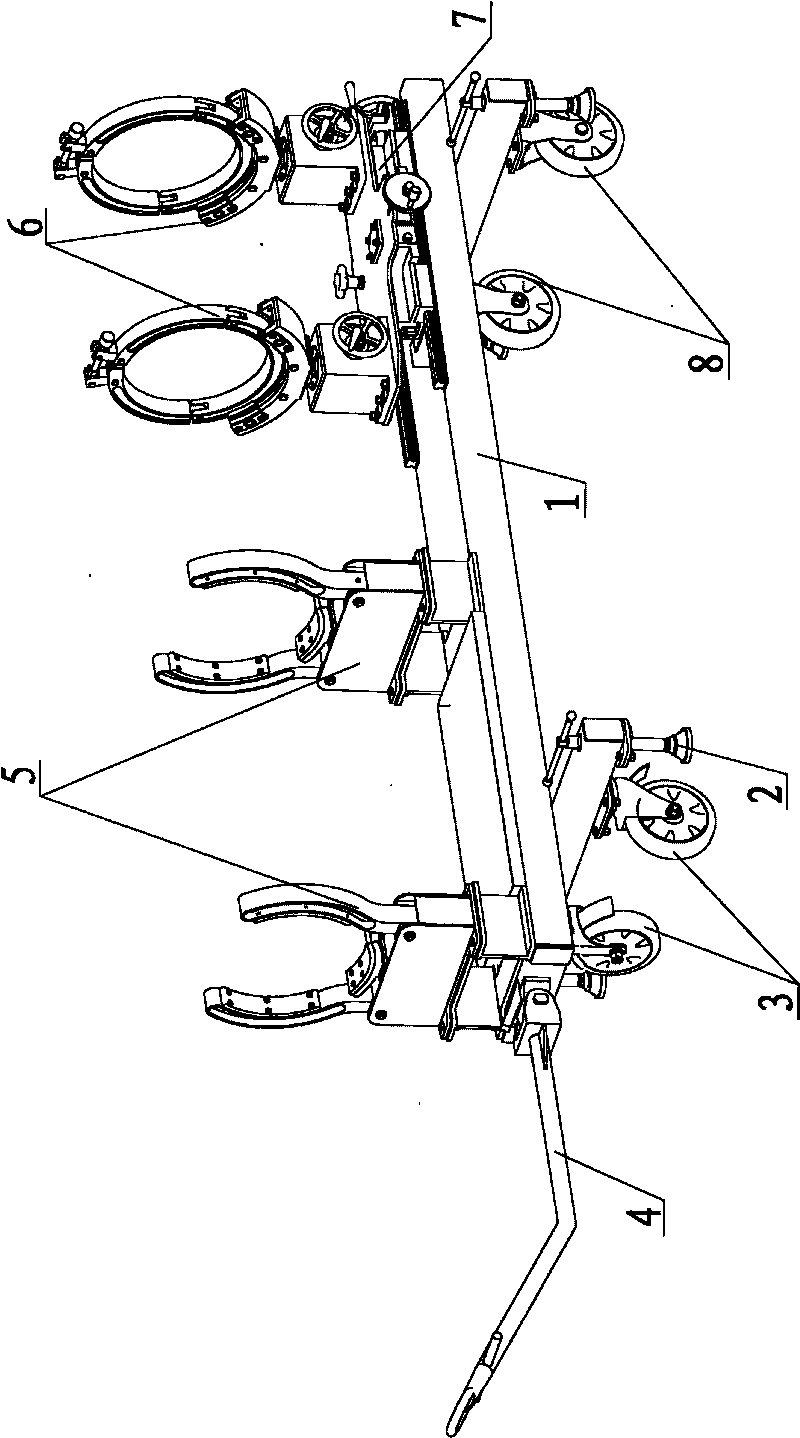

[0030] exist figure 1 Among them, a mechanical product assembly platform includes a platform body 1, an adjustment platform 7 is provided at one end of the upper part of the platform body 1, a rolling clamping device 6 is provided on the adjustment platform 7, and a self-clamping device is provided at the other end of the platform body 1. 5. The front end of the table body 1 is provided with a drawbar 4, and the lower front end of the table body 1 is provided with universal casters 3 so as to facilitate short-distance movement and turning. The lower rear end of the table body 1 is provided with two directional casters 8, and the The four corners of the lower part are provided with four universal screw feet, which are convenient for adjusting the platform body 1 when docking at a fixed location.

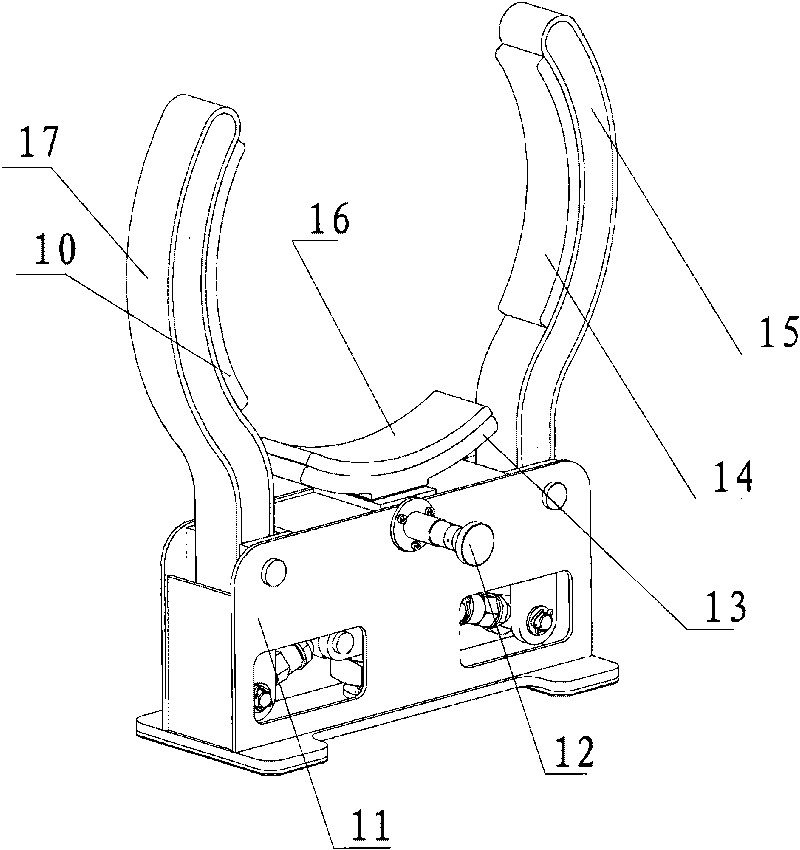

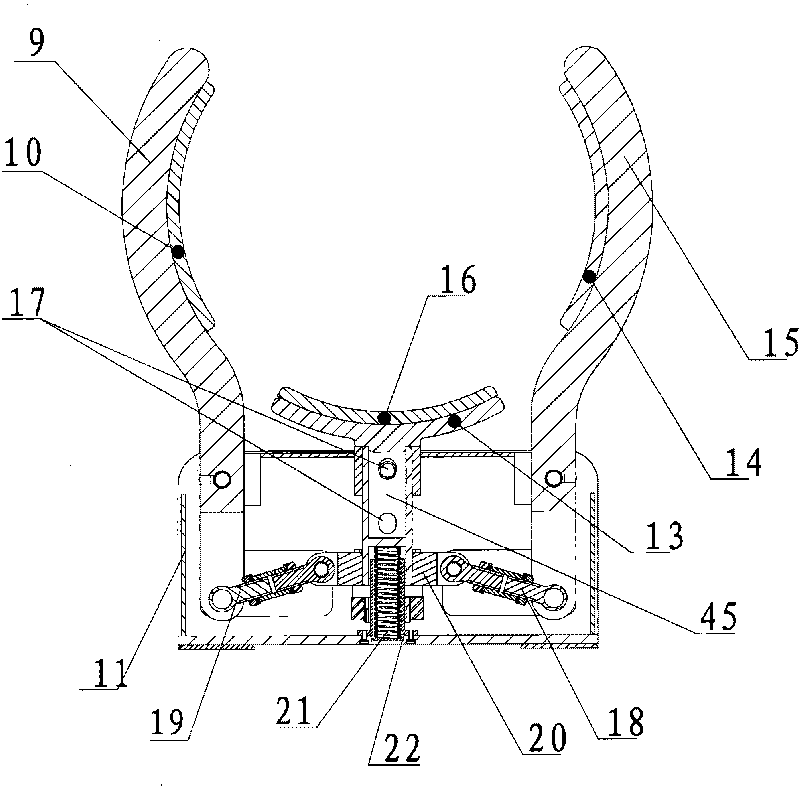

[0031] exist figure 2 , 3 Among them, the self-clamping device of the mechanical product assembly platform includes an installation shell 11, and the two sides of the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com