Synthetic method of N-(n-butyl) thiophosphoric triamide

A technology of n-butylthiophosphoric triamide and its synthesis method, which is applied in the fields of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the difficulty of separation and recycle triethylamine cumbersome procedures and equipment, difficulty in final product separation and purification, and unfavorable for large-scale industrial production, to achieve the effect of cheap raw materials, low equipment requirements, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

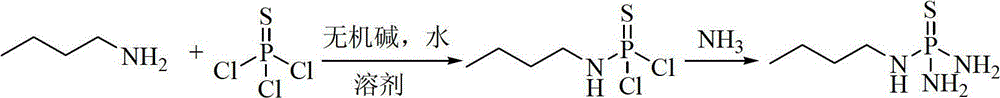

Method used

Image

Examples

Embodiment 1

[0022] Put 200g of solvent (dichloromethane) and 34.3g (0.20mol) of thiophosphoryl chloride into the reaction bottle, stir and cool down to -5~0°C, while adding 15.4g (0.21mol) of n-butylamine dropwise, dropwise Add 26.7g (0.2mol) of 30% sodium hydroxide solution, control the dropping speed of the two, and finish adding the two at the same time for about 1 hour. After the drop is completed, react for 1 hour at -5 ~ 0°C, and detect sulfur by liquid phase (HPLC). After the phosphorus oxychloride reaction is complete, let stand to separate the layers, take the organic layer, and under the condition of stirring, pass 15.0g (0.88mol) of ammonia gas into the organic layer at -5 ~ 0°C, and the liquid phase (HPLC) detects that the reaction is complete After that, ammonium chloride was removed by filtration, and about 130 g of the solvent (dichloromethane) was recovered from the filtrate under reduced pressure, and the residue was cooled to 0°C to crystallize for 3 hours, filtered, and ...

Embodiment 2

[0024] Put 200g of solvent (dichloromethane) and 34.3g (0.20mol) of thiophosphoryl chloride into the reaction bottle, stir and cool down to -5~0°C, while adding 15.4g (0.21mol) of n-butylamine dropwise, dropwise Add 38g (0.2mol) of 30% potassium hydroxide solution, control the dropping speed of the two, and finish adding the two at the same time for about 1 hour. After the phosphorus oxychloride reaction is complete, let stand to separate layers, take the organic layer, and under the condition of stirring, pass 15.0 g (0.88 mol) of ammonia gas into the organic layer at -5 ~ 0 ° C, and liquid phase (HPLC) detects that after the reaction is complete , filtered to remove ammonium chloride, and the filtrate recovered about 130g of solvent (dichloromethane) under reduced pressure, and the residue was cooled to 0°C to crystallize for 3 hours, filtered, and dried to obtain 28.1g of white crystal N-butylthiophosphoric triamide, Melting point: 57.3-58.5°C, yield: 84.2%, content detecte...

Embodiment 3

[0026] Put 200g of solvent (dichloromethane) and 34.3g (0.20mol) of thiophosphoryl chloride into the reaction bottle, stir and cool down to -5~0℃, while adding 22.0g (0.30mol) of n-butylamine dropwise, dropwise Add 13.3g (0.1mol) of 30% sodium hydroxide solution, control the dropping speed of the two, and drop both at the same time for about 1 hour. After the drop is completed, react for 1 hour at -5 ~ 0°C, and detect sulfur by liquid phase (HPLC). After the phosphorus oxychloride reaction is complete, let stand to separate the layers, take the organic layer, and under the condition of stirring, pass 15.0g (0.88mol) of ammonia gas into the organic layer at -5 ~ 0°C, and the liquid phase (HPLC) detects that the reaction is complete After that, ammonium chloride was removed by filtration, and about 130 g of the solvent (dichloromethane) was recovered from the filtrate under reduced pressure, and the residue was cooled to 0°C to crystallize for 3 hours, filtered, and dried to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com