Synthesizing method of active compound of chlorpyrifos

A synthesis method and technology of chlorpyrifos are applied in the synthesis field of producing chlorpyrifos original drug, can solve problems such as low crude oil content of chlorpyrifos, high toxicity of organic solvent, long process route, etc., achieve less harm to human, improve yield and purity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

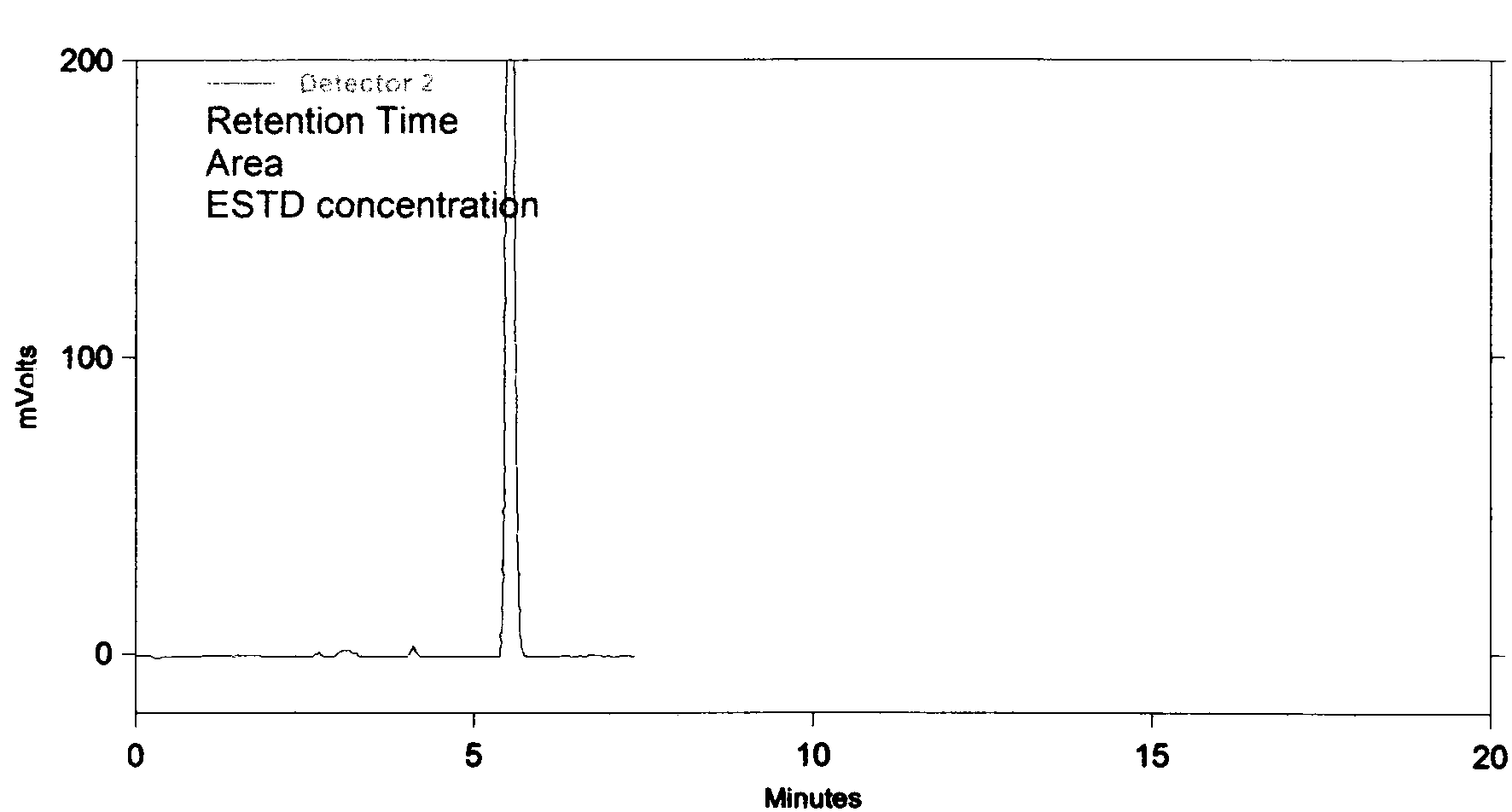

Image

Examples

Embodiment 1

[0009] Example 1: In a reaction kettle, add 200g of 2,3,5,6-tetrachloropyridine, 200g of water, 300g of 30% NaOH, slowly raise the temperature to between 145°C and 150°C for 5 hours, then cool down to room temperature and discharge to obtain 210g of sodium 3,5,6-triclopyridinate (tested content 88.30%) is set aside, put 150g of water and 0.1g of emulsifier into another reaction kettle (the composition of the emulsifier is 32.5% of calcium dodecylbenzenesulfonate, Alkylaryl polyoxyethylene polyoxypropylene ether 25.5%, nonylphenol polyoxyethylene ether 22%, toluene 20%), 0.1g catalyst 4-dimethylaminopyridine, stir for 15 minutes, and then add 3,5,6 - Sodium triclopyridinate 60g, warm up to 30°C, and stir for 30 minutes, add 47.8g of O, O-diethylthiophosphoryl chloride (content 99.1%) dropwise at 30-40°C, and use during the reaction Soda ash adjusts the pH value of the system between 8.5 and 9.0, then heats up to 43 to 48°C for 3 hours and keeps warm for 3 hours at 55 to 60°C fo...

Embodiment 2

[0010] Example 2: In the reaction kettle, add 1000g 2,3,5,6-tetrachloropyridine, 1000g water, 1540g 30% NaOH, slowly raise the temperature to between 145°C and 150°C and keep it warm for 5 hours, then cool down to room temperature and discharge to obtain 1010g3,5, Sodium 6-trichloropyridinate (tested content 86.575%) is used for later use, and 1.5L of water and 1g of emulsifier are put into another reaction kettle (the composition of the emulsifier is 32.5% of calcium dodecylbenzenesulfonate, alkyl aryl Polyoxyethylene polyoxypropylene ether 25.5%, nonylphenol polyoxyethylene ether 22%, toluene 20%), 1g catalyst 4-dimethylaminopyridine, stir for 15 minutes, and then add 3,5,6-trichloropyridinol Sodium 612.5g, heat up to 30°C, and stir for 30 minutes, drop O, O-diethylthiophosphoryl chloride (content 99.1%) 480g between 30°C and 40°C, adjust the pH value of the system with soda ash during the reaction Between 8.5 and 9.0, then heat up to 43-48°C for 3 hours and 55-60°C for 2 ...

Embodiment 3

[0011] Example 3: In the reaction kettle, add 1000g 2,3,5,6-tetrachloropyridine, 1000g water, 1540g 30% NaOH, slowly raise the temperature to 150°C-155°C and keep it warm for 5 hours, then cool down to room temperature and discharge to obtain 1000g3,5, Sodium 6-trichloropyridinate (tested content 87.50%) is used for later use, put 1.5L water and 1g emulsifier into another reaction kettle (the emulsifier composition is calcium dodecylbenzenesulfonate 32.5%, alkylaryl Polyoxyethylene polyoxypropylene ether 25.5%, nonylphenol polyoxyethylene ether 22%, toluene 20%), 1g catalyst 4-dimethylaminopyridine, stir for 15 minutes, and then add 3,5,6-trichloropyridinol Sodium 612.0g, heat up to 30°C, and stir for 30 minutes, add O, O-diethylthiophosphoryl chloride (content 99.1%) 480g dropwise between 30°C and 40°C, adjust the pH value of the system with soda ash during the reaction Between 8.5 and 9.0, then heat up to 43-48°C for 3 hours and 55-60°C for 2 hours, filter to the washing k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com