Phosphorus and nitrogen flame retardant and preparation method thereof

A phosphorus-nitrogen flame retardant and flame retardant technology, applied in the field of flame retardants, can solve problems such as environmental safety hazards and application restrictions, and achieve the effects of good flame retardant effect, simple production conditions and reduced dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

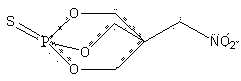

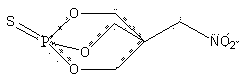

Image

Examples

Embodiment 1

[0017] Add 2,2-dimethylol-3-nitro-1-propanol (16.51g, 0.1mol) into a 500ml three-neck flask equipped with a thermometer, a 100ml constant pressure dropping funnel, a magnet and an exhaust gas absorption device, Triethylamine (35.42g, 0.35mol) and 200ml chloroform, turn on the magnetic stirring, dissolve phosphorus trichloride (17.79g, 0.105mol) in 50ml chloroform, add to the constant pressure funnel, at 0~5℃, Slowly added dropwise to the three-necked flask. After the dropwise addition, the reaction was continued for 6 hours. After the reaction, the reactant was distilled, and the low boiling point solvent was recovered and recycled, while the high boiling point residue was washed with deionized water and filtered to obtain a solid that was vacuum dried at 40°C for 6 hours. Obtain 18.32 grams of white powdery phosphorus nitrogen flame retardant solid, yield 93%.

Embodiment 2

[0019] Add 2,2-dimethylol-3-nitro-1-propanol (16.51g, 0.1mol) into a 500ml three-neck flask equipped with a thermometer, a 100ml constant pressure dropping funnel, a magnet and an exhaust gas absorption device, Pyridine (27.69g, 0.35mol) and 200ml of dichloromethane, turn on the magnetic stirring, dissolve phosphorus trichloride (17.79g, 0.105mol) in 50ml of dichloromethane, add to the constant pressure funnel, at 0~5℃ Slowly drop it into the three-neck flask. After the dropwise addition, the reaction was continued for 6 hours. After the reaction, the reactant was distilled, and the low boiling point solvent was recovered and recycled, while the high boiling point residue was washed with deionized water and filtered to obtain a solid that was vacuum dried at 40°C for 6 hours. Obtain 18.81 grams of solid white powder phosphorus nitrogen flame retardant, yield 95%.

Embodiment 3

[0021] Add 2,2-dimethylol-3-nitro-1-propanol (16.51g, 0.1mol) into a 500ml three-neck flask equipped with a thermometer, a 100ml constant pressure dropping funnel, a magnet and an exhaust gas absorption device, Sodium carbonate (18.58g, 0.175mol) and 200ml acetonitrile, turn on the magnetic stirring, dissolve phosphorus trichloride (17.79g, 0.105mol) in 50ml acetonitrile, add to the constant pressure funnel, at 0~5℃, slowly Add dropwise to a three-neck flask. After the dropwise addition, the reaction was continued for 6 hours. After the reaction, the reactant was distilled, and the low boiling point solvent was recovered and recycled, while the high boiling point residue was washed with deionized water and filtered to obtain a solid that was vacuum dried at 40°C for 6 hours. Obtain 17.71 grams of white powdery phosphorus nitrogen flame retardant solid, yield 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com