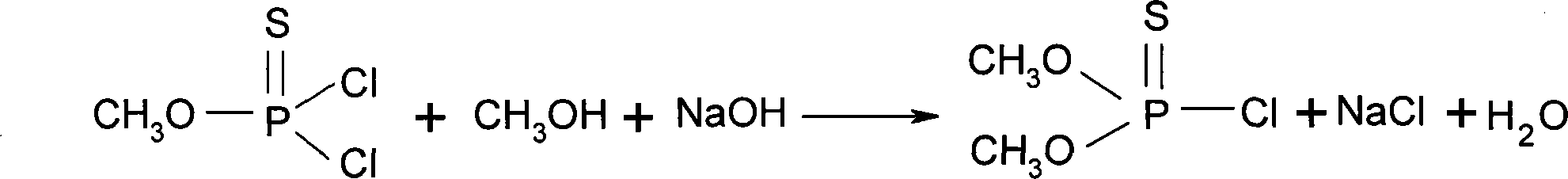

Method for continuous production of 0,0-dimethyl thiophosphoryl chloride

A technology of dimethyl thiophosphoryl and methyl thiophosphoryl dichloride, applied in the field of continuous preparation of O, can solve the problems of low equipment utilization, long reaction time, low yield and the like, and it is extremely easy to achieve production capacity Amplify, improve labor productivity, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1 mol of O-dimethyl thiophosphoryl dichloride and 4.8 mol of methanol are added to the first-stage reactor, while 0.46 mol of alkali is added to the first-stage reactor, and the temperature of each stage of the reactor is controlled as follows: -5~ At 0°C, 0.31 mol of alkali is added to the second stage reactor, 0.16 mol of alkali is added to the third stage reactor, and 0.12 mol of alkali is added to the fourth stage reactor. The reaction mixture was washed with water and separated into layers to obtain O, O-dimethyl thiophosphoryl chloride with a mass content of 91.3%.

Embodiment 2

[0021] 100kmol of O-dimethylthiophosphoryl dichloride and 600kmol of methanol are added to the first stage reactor, while 35kmol of alkali is added to the first stage reactor, and the temperature of each stage of the reactor is controlled as follows: -8~-2 ℃, add 20kmol alkali into the second stage reactor, 15kmol alkali into the third stage reactor, 10kmol alkali into the fourth stage reactor, and 10kmol alkali into the fifth stage reactor. Add 5 kmol alkali to the reactor, add 5 kmol alkali in the seventh-stage reactor, and the reaction mixture enters the oil-water separator after being washed with water to obtain O, O-dimethyl thiophosphoryl chloride with a mass content of 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com