Microchannel synthesis technology for N-(n-Butyl)thiophosphoric triamide

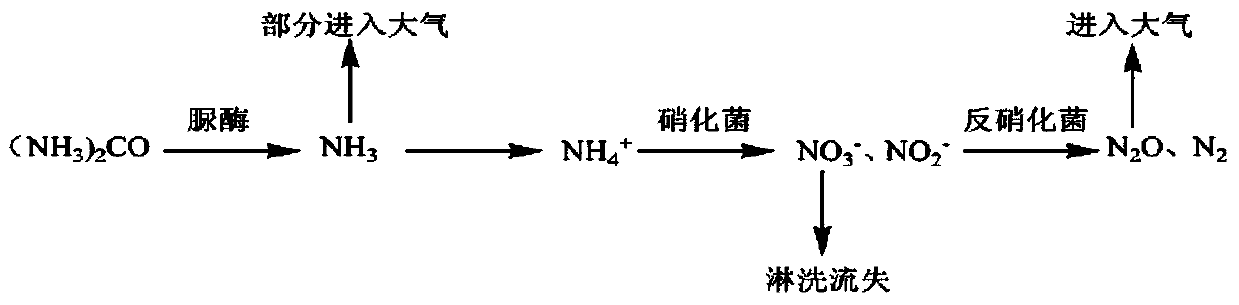

A technology of n-butyl thiophosphoric triamide and synthesis technology, which is applied in the field of micro-channel synthesis technology of n-butyl thiophosphoric triamide, can solve the difficulty of separation and purification, serious back-mixing of materials and long reaction time and other problems, to achieve the effect of improving the total yield and purity, less three wastes, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

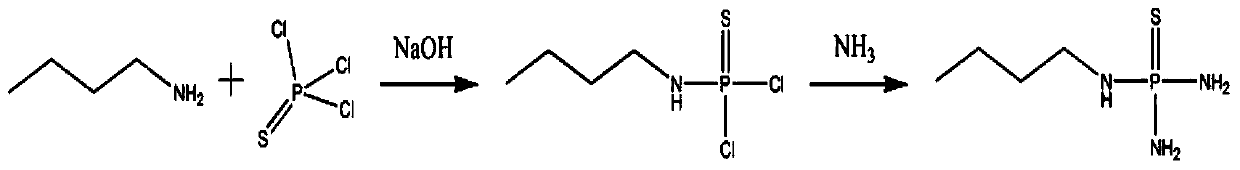

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, 3.39kg (2.0mol) of phosphorus trichloride and 1.695kg of dichloromethane are mixed, and 1.465kg (2.0mol) of n-butylamine is added to 1.465kg of dichloromethane and injected into the Corning microchannel simultaneously with a plunger metering pump respectively. Reactor feed port, the other feed port injects 10% NaOH solution 8kg (2mol) with metering plunger pump, adjusts the back pressure valve to 0MPa, controls and adjusts the material entering speed, uses up above-mentioned three kinds of materials evenly at the same time, temperature control At 10 °C, the reaction time is 20 s. When the material enters the third plate, it is cooled to 15°C, and the fourth plate is fed with NH at 15°C 3 14.96kg (8.8mol), the material is received at the outlet, the material is separated from the gas and liquid, and the inorganic layer is separated at rest. After the organic layer is evaporated to part of the dichloromethane, it is cooled and crystallized, filtered to...

Embodiment 2

[0027] In this embodiment, 3.39kg (2.0mol) of phosphorus trichloride and 3.39kg of dichloromethane are mixed, and 1.465kg (2.0mol) of n-butylamine is added to 2.93kg of dichloromethane and injected into the Corning microchannel simultaneously with a plunger metering pump respectively. Reactor feed port, another feed port injects 10% NaOH solution 8kg (2.0mol) with metering plunger pump, adjusts the back pressure valve to be 0.25MPa, controls and regulates the feed rate of material, uses up above-mentioned three kinds of materials evenly simultaneously, The temperature was controlled at 50°C, and the reaction time was 25s. When the material enters the third plate, it is cooled to 15°C, and the fourth plate is fed with NH at 15°C3 14.96kg (8.8mol), the material is received at the outlet, the material is separated from the gas and liquid, and the inorganic layer is separated at rest. After the organic layer is evaporated to part of the dichloromethane, it is cooled and crystallize...

Embodiment 3

[0030] In this embodiment, 3.39kg (2.0mol) of phosphorus trichloride and 2.712kg of dichloromethane are mixed, and 1.465kg (2.0mol) of n-butylamine is added to 2.637kg of dichloromethane and injected into the Corning microchannel simultaneously with a plunger metering pump respectively. Reactor feed port, another feed port injects 10% NaOH solution 8kg (2.0mol) with metering plunger pump, adjusts the back pressure valve to be 0.5MPa, controls and regulates the feed rate of material, evenly uses up above-mentioned three kinds of materials simultaneously, The temperature was controlled at 25°C, and the reaction time was 30s. When the material enters the third plate, it is cooled to 15°C, and the fourth plate is fed with NH at 15°C 3 14.96kg (8.8mol), the material is received at the outlet, the material is separated by gas and liquid, and the inorganic layer is separated at rest. After the organic layer is evaporated to part of the dichloromethane, it is cooled and crystallized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com