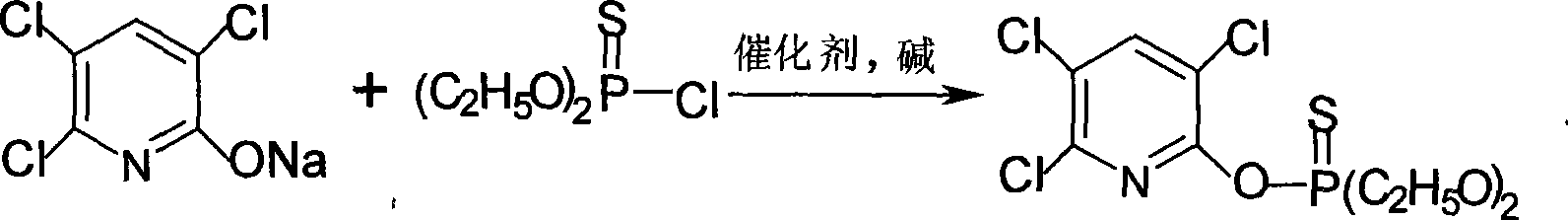

Preparation of O,O-diethyl-O-(3,5,6- trichloro-2-pyridinyl)thiophosphate

A technology of phosphorothioate and ethyl phosphorothioate, applied in the O field, can solve the problems of increased by-products, difficult waste water treatment, large loss of raw materials, etc., and achieves the effects of easy treatment, less waste water, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 2000ml three-necked flask, add 1000g of water, 300g of 3,5,6-trichloropyridin-2-alcohol sodium with a weight concentration of 85%, 1.0g of 4-dimethylaminopyridine, 1.5g of tetrabutylammonium bromide, and three Ethylenediamine 1.0g, add 60kg of sodium hydroxide solution with a weight concentration of 30%, to make the pH value reach 11.0, heat to 45°C, add dropwise O, O-diethylsulfur with a weight concentration of 98% within 0.5 hours Phosphoryl chloride 225g, then kept at 45°C for 2.5 hours, filtered while hot, filtered to remove solid impurities, cooled to 30°C, filtered, washed once with 100ml water, dried to obtain chlorpyrifos 401kg, HPLC analysis content 97.09%, yield 96.05 %.

Embodiment 2

[0026] In a 2000ml three-necked flask, add 1000g of water, 300g of 3,5,6-trichloropyridin-2-alcohol sodium with a weight concentration of 85%, 1.0g of 4-dimethylaminopyridine, 1.0g of 4-methylmorpholine, and three Add 1.5g of ethyl benzyl ammonium chloride, add 60g of sodium hydroxide solution with a weight concentration of 30%, make the pH value reach 11.0, heat to 45-70°C, add 98% O, O-distillate dropwise within 0.5-2.0 hours Ethyl thiophosphoryl chloride 222g, then keep warm at 45-70°C for 3.0 hours, filter while hot, remove solid impurities, cool to 30°C, filter, wash once with 100ml water, dry to obtain chlorpyrifos 398g HPLC analysis content 96.91% , yield 95.15%.

Embodiment 3

[0028] In a 2000ml three-neck flask, add 1000g of water, 300g of 85% 3,5,6-trichloropyridin-2-alcohol sodium, 1.0g of 4-dimethylaminopyridine, 1.0g of tetrabutylammonium bromide, and 1.0g of triethylbenzyl Ammonium chloride 1.5g, add 30% sodium hydroxide solution 65g, make pH value reach 12.0, be heated to 70 ℃, in 2.0 hours, add dropwise O, O-diethylthiophosphoryl chloride 226g of weight concentration 98%, Then keep it warm at 70° C. for 3.5 hours, filter while it is hot, remove solid impurities, cool to 30° C., filter, wash once with 100 ml of water, and dry to obtain chlorpyrifos 405 g, HPLC analysis content 96.58%, yield 96.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com