Method for extracting and separating ginkgo leaf polyprenol acetic ester from ginkgo leaf by supercritical carbon oxide

A technology of leaf polyprenyl acetate and carbon dioxide, which is applied in the field of double extraction and separation of ginkgo biloba polyprenyl acetate, can solve the problems of difficult industrial production, low product yield, and large consumption. Achieve the effects of shortening the production cycle, high content and purity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

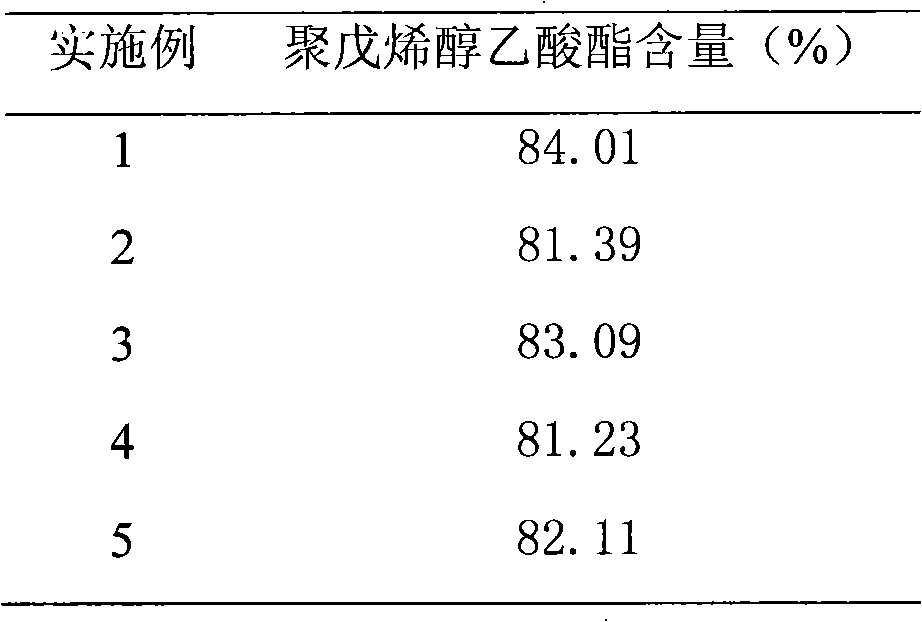

Examples

Embodiment 1

[0017] Using supercritical carbon dioxide to extract and separate ginkgo biloba polypentenol acetate from ginkgo biloba, firstly, 10 kilograms of ginkgo biloba powder with a crushed particle size of 60 mesh is charged into the extraction kettle, and the carbon dioxide high-pressure pump is started to increase the pressure to 30 MPa, the supercritical carbon dioxide is sent into the extraction kettle, the temperature of the extraction kettle is 65℃, the carbon dioxide fluid after passing through the extraction kettle enters the first and second two separation kettles in series, the temperature of the first stage separation kettle is 40 ℃, the pressure is 5 MPa, the temperature of the second-stage separation kettle is 30 ℃, the pressure is 3 MPa, and the carbon dioxide fluid is refrigerated and compressed back to the gas storage tank. The carbon dioxide flow rate is 0.3-1.2 cubic meters per hour. After 6 hours of extraction, stop the pump and depressurize, release the ginkgo bilob...

Embodiment 2

[0020] First, put 20 kg of ginkgo leaf powder with a crushed particle size of 80 mesh into the extraction kettle, start the carbon dioxide high-pressure pump, increase the pressure to 25 MPa, and send the supercritical carbon dioxide into the extraction kettle. The temperature of the extraction kettle is 60 ℃. The carbon dioxide fluid after the kettle enters the first-stage and second-stage two separation kettles in series. The temperature of the first-stage separation kettle is 30°C and the pressure is 5 MPa, and the temperature of the second-stage separation kettle is 30°C and the pressure is 4 MPa. The carbon dioxide fluid is refrigerated and compressed back to the gas storage tank. The carbon dioxide flow rate is 0.3-1.2 cubic meters per hour. After 10 hours of circulating extraction, the pump is stopped and the pressure is reduced, and the ginkgo leaf extract residue is released from the extraction kettle. Discharge about 1700 grams of ginkgo biloba polypentenol acetate oin...

Embodiment 3

[0023] Firstly, 15 kg of Ginkgo biloba powder with a crushed particle size of 100 mesh is put into the extraction kettle, the high pressure carbon dioxide pump is started, and the pressure is increased to 30 MPa, and the supercritical carbon dioxide is fed into the extraction kettle. The temperature of the extraction kettle is 55℃. The carbon dioxide fluid after the kettle enters the first and second two separation kettles in series. The temperature of the first-stage separation kettle is 35°C and the pressure is 5 MPa, and the temperature of the second-stage separation kettle is 30°C and the pressure is 4 megapascals. The carbon dioxide fluid is refrigerated and compressed back to the gas storage tank. The carbon dioxide flow rate is 0.3-1.2 cubic meters per hour. After 8 hours of circulating extraction, the pump is stopped and the pressure is reduced, and the ginkgo leaf extract is released from the extraction kettle. Discharge about 1360 grams of ginkgo biloba polypentenol ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com