A preparation method of cofs@hpan nanofiltration composite membrane

A composite membrane and nanofiltration technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of chemical resistance and cycle stability that have not been reported, and hybrid membranes with poor mechanical properties and service stability , anti-pollution and unstable flux recovery rate, etc., to achieve the effects of excellent cycle stability, eliminating solvent recovery and three waste treatment, excellent permeability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

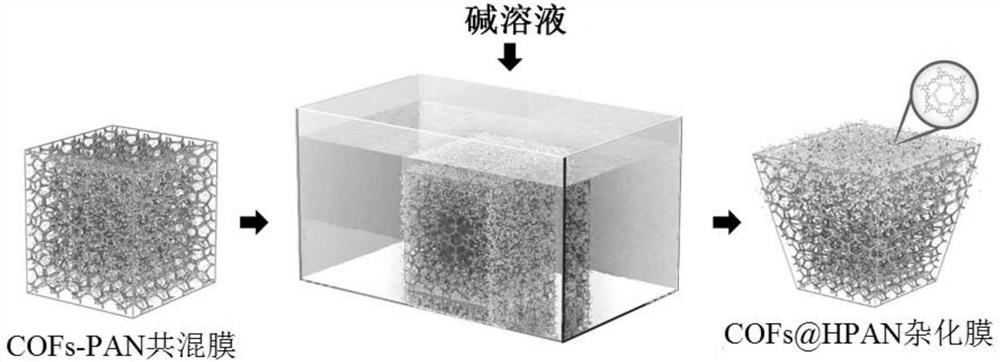

[0023] The invention provides a method for preparing a COFs@HPAN nanofiltration composite membrane (method for short), which is characterized in that the method comprises the following steps:

[0024] 1) Add COFs and meltable PAN-based copolymers into a twin-rotor high-speed mixer, and mix at a speed of 500-1500 rpm and a temperature of 200-230°C for 5-60 minutes to obtain COFs-PAN masterbatch;

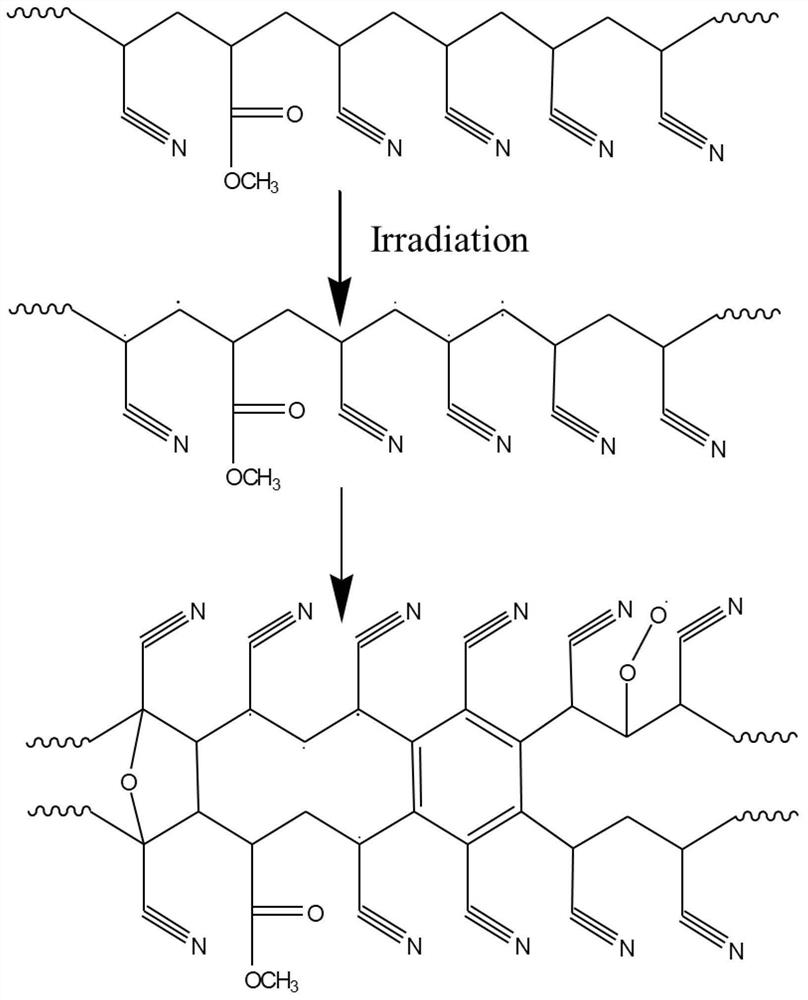

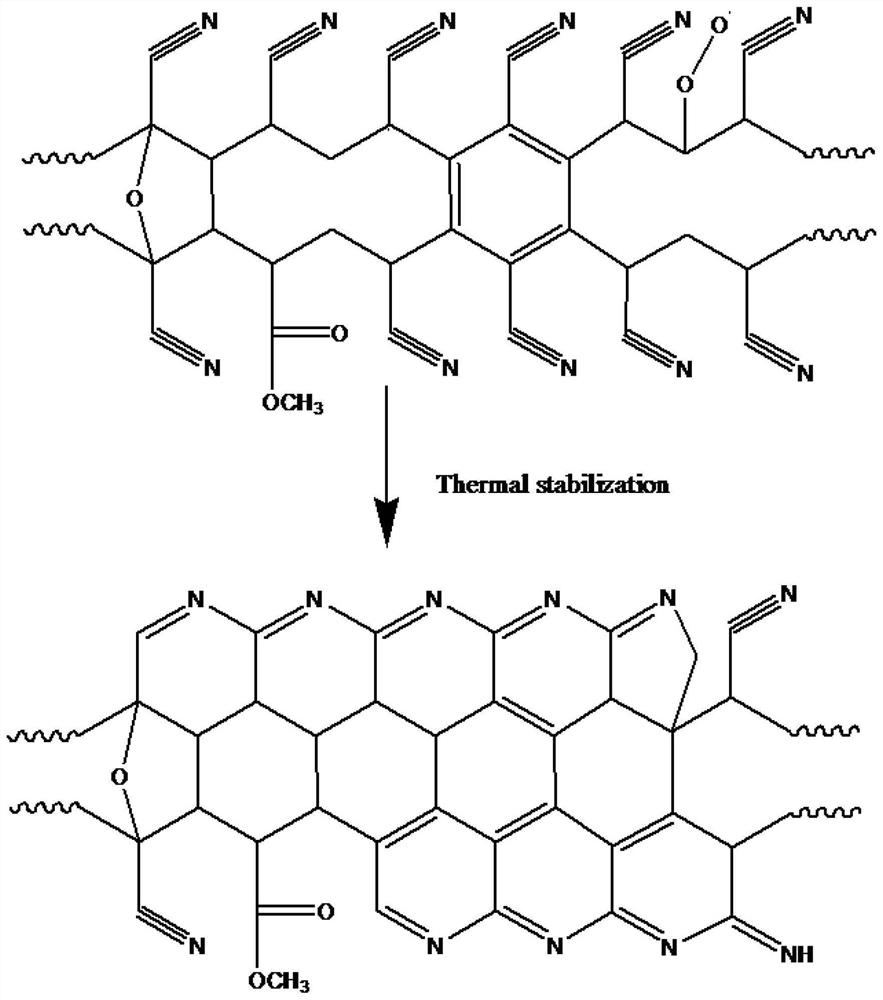

[0025] In step 1), the meltable PAN-based copolymer can be prepared using the materials or preparation methods disclosed in patent ZL201510694690.X or ZL200810053936.5.

[0026] In step 1), the COFs can be but not limited to COF-1 (pore size 1.5nm), COF-5 (pore size 2.7nm), COF-8 (pore size 1.64nm), COF-10 (pore size 3.2nm), COF -DhaTab (pore diameter 3.7nm), COF-TpPa-1 (pore diameter 1.8nm), COF-TpPa-2 (pore diameter 1.5nm), COF-TpBD (pore diameter 2.4nm), COF-TpBD-Me 2 (pore size 2.3nm), COF-TpBD-(OMe) 2 At least one of (pore diameter 2.3nm), COF-TpTGcl (pore diameter 1.3nm), COF-...

Embodiment 1

[0055] 1) Add 50g COF-TpBD-Me 2 Mix with 200g of meltable PAN at 1000rpm and 210°C for 20min to prepare COF-TpBD-Me 2 COFs-PAN masterbatch with a content of 20wt%;

[0056] 2) Stir the composite diluent composed of 180g COFs-PAN masterbatch, 700g caprolactam and 320g glycerol triacetate at 150°C under the protection of nitrogen for 3 hours and defoam for 24 hours to obtain a uniform and foam-free casting solution; The film solution was poured into a mold at 110°C for calendering, and after curing in an air bath at 25°C for 12 hours, the compound diluent was extracted and removed in an aqueous solution to obtain a COFs-PAN blend flat film;

[0057] 3) Primary cross-linking: put the COFs-PAN blend flat film obtained in step 2) into 10wt% NaOH solution for hydrolysis for 2 hours, rinse with ethanol and distilled water to remove NaOH on the film surface, and dry in a vacuum oven at 60°C for 24 hours Obtain the dry COFs@HPAN hybrid membrane;

[0058] Secondary cross-linking: put...

Embodiment 2

[0062] 1) Mix 100g of COF-TpPa-2 and 150g of meltable PAN at a speed of 500rpm and 200°C for 40min to prepare a COFs-PAN masterbatch with a COF-TpPa-2 content of 40wt%;

[0063] 2) Mix 220g COFs-PAN masterbatch, 810g caprolactam and 90g dibutyl sebacate in a composite diluent, stir for 3 hours at 160°C under argon protection, and defoam for 24 hours to obtain a uniform and foam-free casting film liquid; then pour the casting solution into a mold at 90°C for calendering, solidify in an air bath at 20°C for 10 hours, extract and remove the composite diluent in a mixed solution of water and ethanol, and obtain a COFs-PAN blended plate membrane;

[0064] 3) Primary cross-linking: put the COFs-PAN blend flat film obtained in step 2) into 25wt% KOH solution and hydrolyze for 0.5h, rinse with ethanol and distilled water to remove KOH on the film surface, and dry in a vacuum oven at 80°C 15h to obtain a dry COFs@HPAN hybrid membrane;

[0065] Secondary cross-linking: place it in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com