A kind of preparation method of 1-naphthylacetic acid

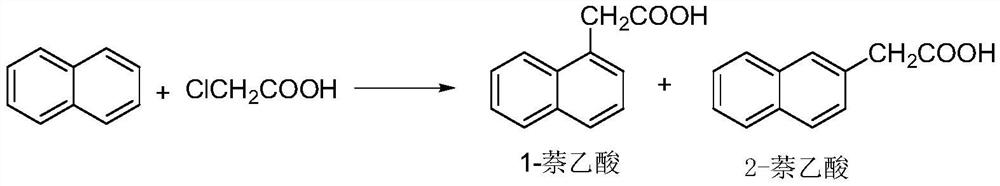

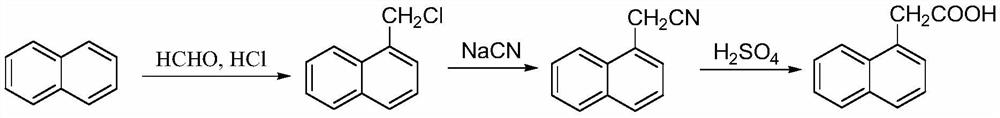

A technology of naphthaleneacetic acid and chloroacetic acid, which is applied in the field of preparation of 1-naphthaleneacetic acid, can solve the problems of reducing production costs, achieve the effects of reducing production costs, solving recycling problems, and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

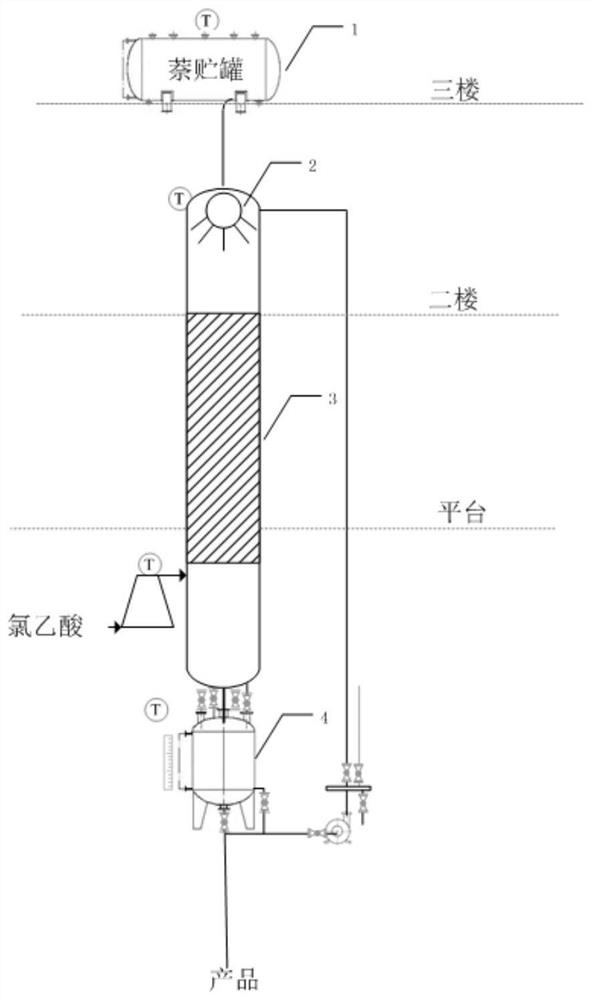

[0032] Example 1: (molar ratio 1:1)

[0033] Feeding is carried out in the reactor 3 that is equipped with 100kg ZSM-5, temperature of reaction is 190 ℃, and the naphthalene feed rate is 95kg / h, and is uniformly dispersed in the reactor by spray head 2 after melting, and the chloroacetic acid feed rate is 70kg / h, after gasification, press into the reactor through the compressor, separate the 1-naphthalene acetic acid and the excess liquid chloroacetic acid mother liquor through the filter press, and the mother liquor circulates the mother liquor through the pipeline to the reactor 3 through the circulating pump; the mother liquor passes through the mother liquor The circulation pump is returned to the reactor. The yield of 1-naphthaleneacetic acid was 95.5%, and the product purity after drying was 98.8%. IR(cm -1 ): 3300-2500, 3065.1, 2915.2, 1699.0, 1414.0, 1220.5, 935.1, 781.2. H NMR spectroscopy (CDCl 3 )δ: 11.9(S, 1H), 7.98-8.00(d, 2H), 7.88-7.90(d, 2H), 7.82-7.84(d, ...

Embodiment 2

[0034] Example 2: (molar ratio 1:10)

[0035] Feeding is carried out in the reactor 3 that is equipped with 100kg ZSM-11, temperature of reaction is 215 DEG C, and naphthalene feed rate is 100kg / h, after melting, uniformly dispersed in reactor by spray head 2, chloroacetic acid feed rate is 734kg / h, after gasification, press into the reactor through the compressor, separate the 1-naphthalene acetic acid and the excess liquid chloroacetic acid mother liquor through the filter press, and the mother liquor circulates the mother liquor through the pipeline to the reactor 3 through the circulating pump; 1-naphthalene The yield of acetic acid was 95.5%, and the product purity after drying was 98.9%.

Embodiment 3

[0036] Example 3: (molar ratio 1:1.36)

[0037]Feeding is carried out in the reactor 3 that 85kg ZSM-11 is housed in, temperature of reaction is 200 ℃, and the naphthalene feed rate is 1000kg / h, and is uniformly dispersed in the reactor by spray head 2 after melting, and the chloroacetic acid feed rate is 734kg / h, after gasification, press into the reactor through the compressor, separate the 1-naphthalene acetic acid and the excess liquid chloroacetic acid mother liquor through the filter press, and the mother liquor circulates the mother liquor through the pipeline to the reactor 3 through the circulating pump; 1-naphthalene The yield of acetic acid was 96.5%, and the product purity after drying was 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com