A kind of preparation method of ternary polyacrylonitrile copolymer for carbon fiber precursor

A technology of carbon fiber precursors and polyacrylonitrile, which is applied in the field of preparation of ternary polyacrylonitrile copolymers for carbon fiber precursors. It can solve the problems of inability to obtain high-performance carbon fibers and difficult control, and achieve easy control of exothermic reactions and reduce flexibility. , performance and the effect of carbonization yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

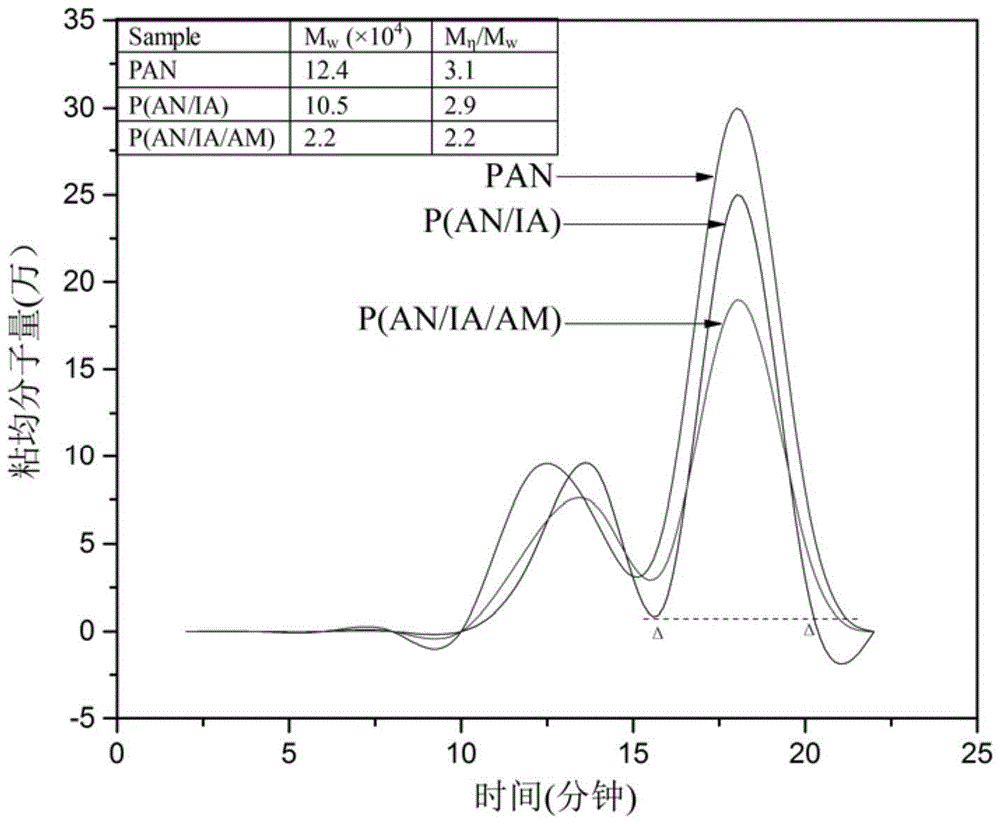

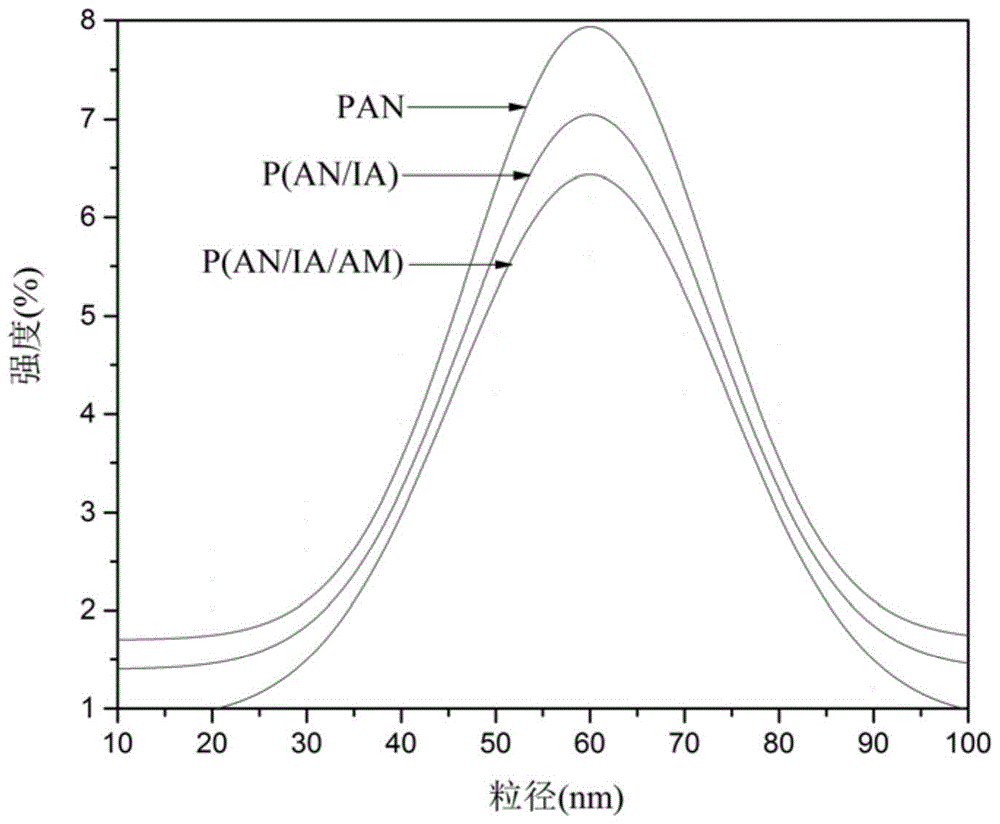

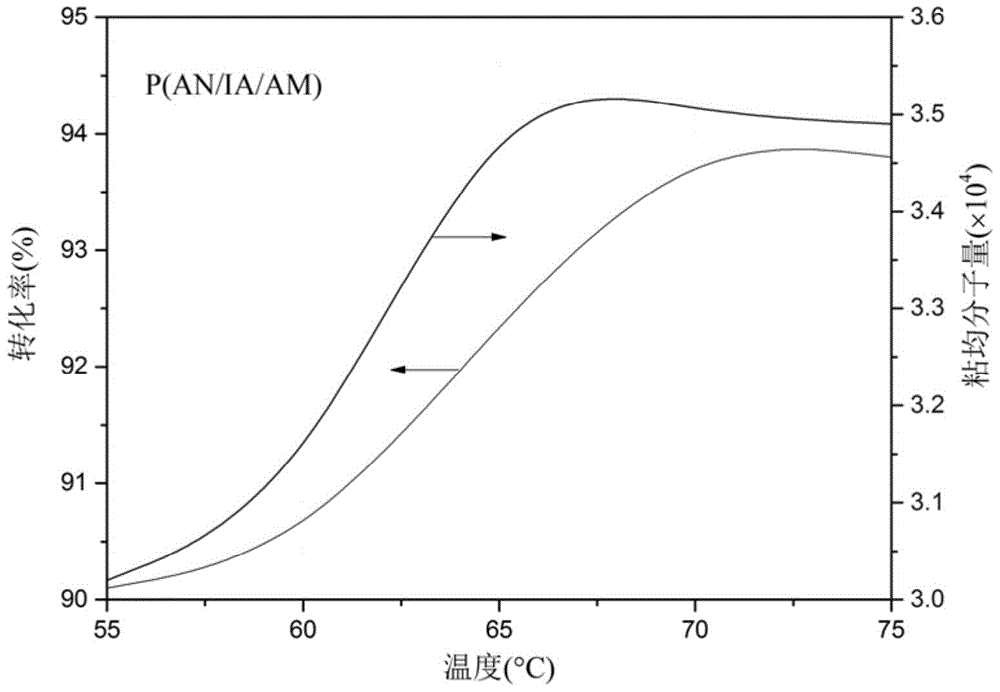

Embodiment 1

[0031] The polymerization reactor was evacuated and circulated with nitrogen for 3 times. 22.31g of acrylonitrile, 0.46g of itaconic acid, 0.23g of polyvinyl alcohol (1755) and 60g of deionized water were added to the 5L glass reactor at 35°C. Blow nitrogen for 30min, heat up to 60℃ and hold at this temperature for 0.5h, then add ammonium persulfate (0.23g / 10gH 2 O) Aqueous solution and completed within 0.5h. After the initiator is added, acrylamide (0.23g / 7gH 2 O) Aqueous solution and finished in 1h. At the same time, keep the reaction at 60℃ for 24 hours, the prepared polyacrylonitrile has a viscosity average molecular weight of 3.4×10 5 g / mol, molecular weight distribution is 2.98. The polymer slurry was filtered, removed from the order, and dried to obtain a white granular powder. The measured copolymer conversion rate was 87.7%. DSC test under nitrogen atmosphere (using TA Company’s Q20 differential scanning calorimeter, rising from 30°C to 310°C at a rate of 5°C / min) show...

Embodiment 2

[0033] The polymerization reactor was evacuated and circulated with nitrogen for 3 times. 22.54g of acrylonitrile, 0.23g of itaconic acid, 0.23g of polyvinyl alcohol (1788) and 60g of deionized water were added to the 5L glass reactor at 35°C. Blow nitrogen for 30min, heat up to 60℃ and hold at this temperature for 0.5h, then add ammonium persulfate (0.23g / 10gH 2 O) Aqueous solution and completed within 0.5h. After the initiator is added, acrylamide (0.23g / 7gH 2 O) Aqueous solution and finished in 1h. At the same time, keep the reaction at 60℃ for 24 hours, the prepared polyacrylonitrile has a viscosity average molecular weight of 3.8×10 5 g / mol, the molecular weight distribution is 3.02. The polymer slurry was filtered, removed from the order, and dried to obtain a white granular powder. The measured copolymer conversion rate was 89.1%. DSC test under nitrogen atmosphere (using TA Company’s Q20 differential scanning calorimeter, rising from 30°C to 310°C at a rate of 5°C / min) ...

Embodiment 3

[0035] The polymerization reactor was evacuated and circulated with nitrogen for 3 times. 22.08g of acrylonitrile, 0.69g of itaconic acid, 0.23g of polyvinyl alcohol (1799) and 60g of deionized water were added to the 5L glass reactor at 35°C. Blow nitrogen for 30min, heat up to 60℃ and hold at this temperature for 0.5h, then add ammonium persulfate (0.23g / 10gH 2 O) Aqueous solution and completed within 0.5h. After the initiator is added, acrylamide (0.23g / 7gH 2 O) Aqueous solution and finished in 1h. At the same time, keep the reaction at 60℃ for 24 hours, the prepared polyacrylonitrile has a viscosity average molecular weight of 4.1×10 5 g / mol, molecular weight distribution is 2.98. The polymer slurry was filtered, removed, and dried to obtain a white granular powder. The measured copolymer conversion rate was 92.4%. DSC test under nitrogen atmosphere (using TA Company’s Q20 differential scanning calorimeter, rising from 30°C to 310°C at a rate of 5°C / min) shows that the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com