Special fixture for micro electrode array on-line horizontal electrospark machining

A technology of array electrodes and special fixtures, applied in the direction of electric processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems that affect the machining accuracy and quality of array holes, the position accuracy is difficult to be guaranteed, and the discharge chips are not easy to discharge, etc., to achieve It is beneficial to the discharge state, high clamping precision, and beneficial to the effect of exclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

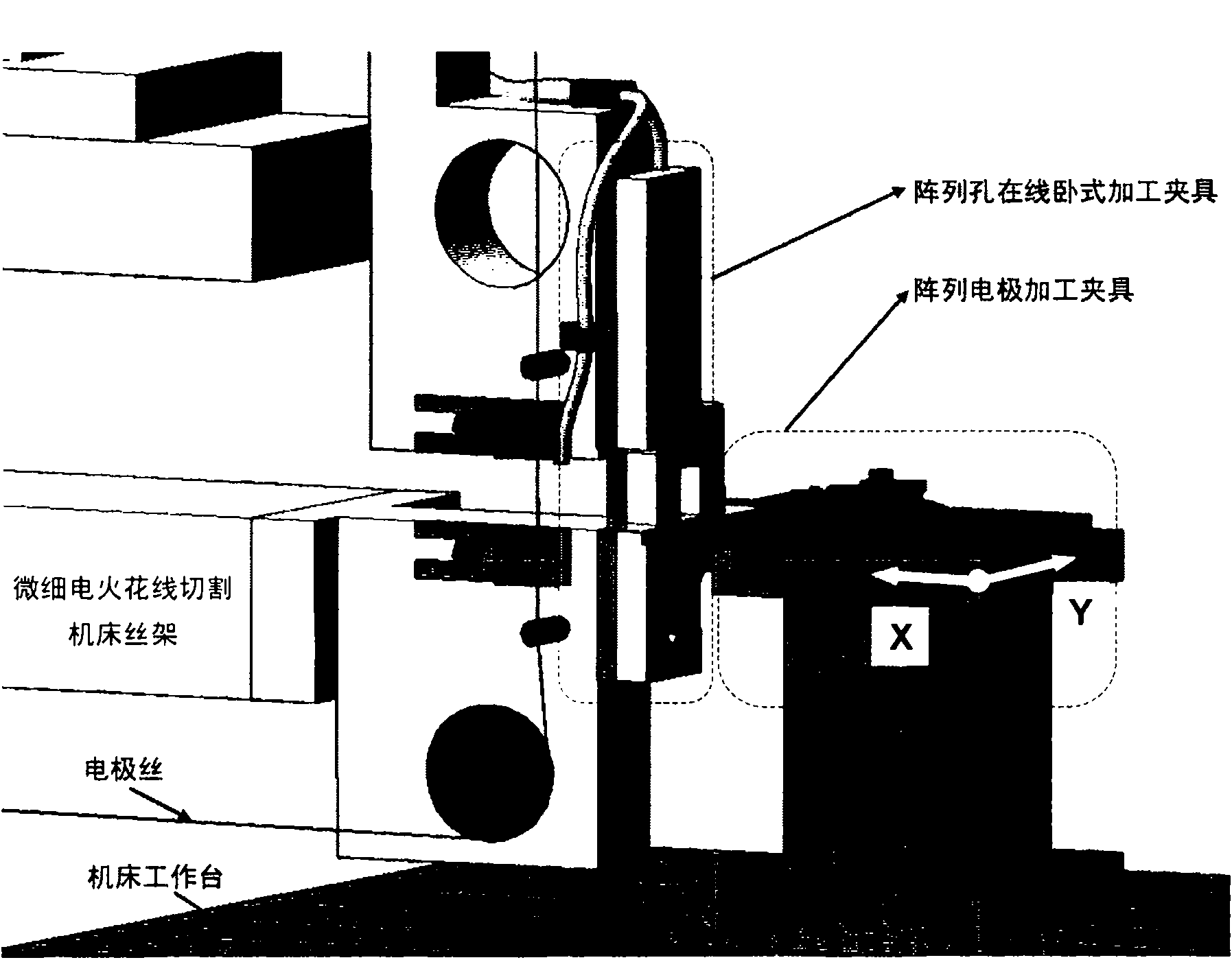

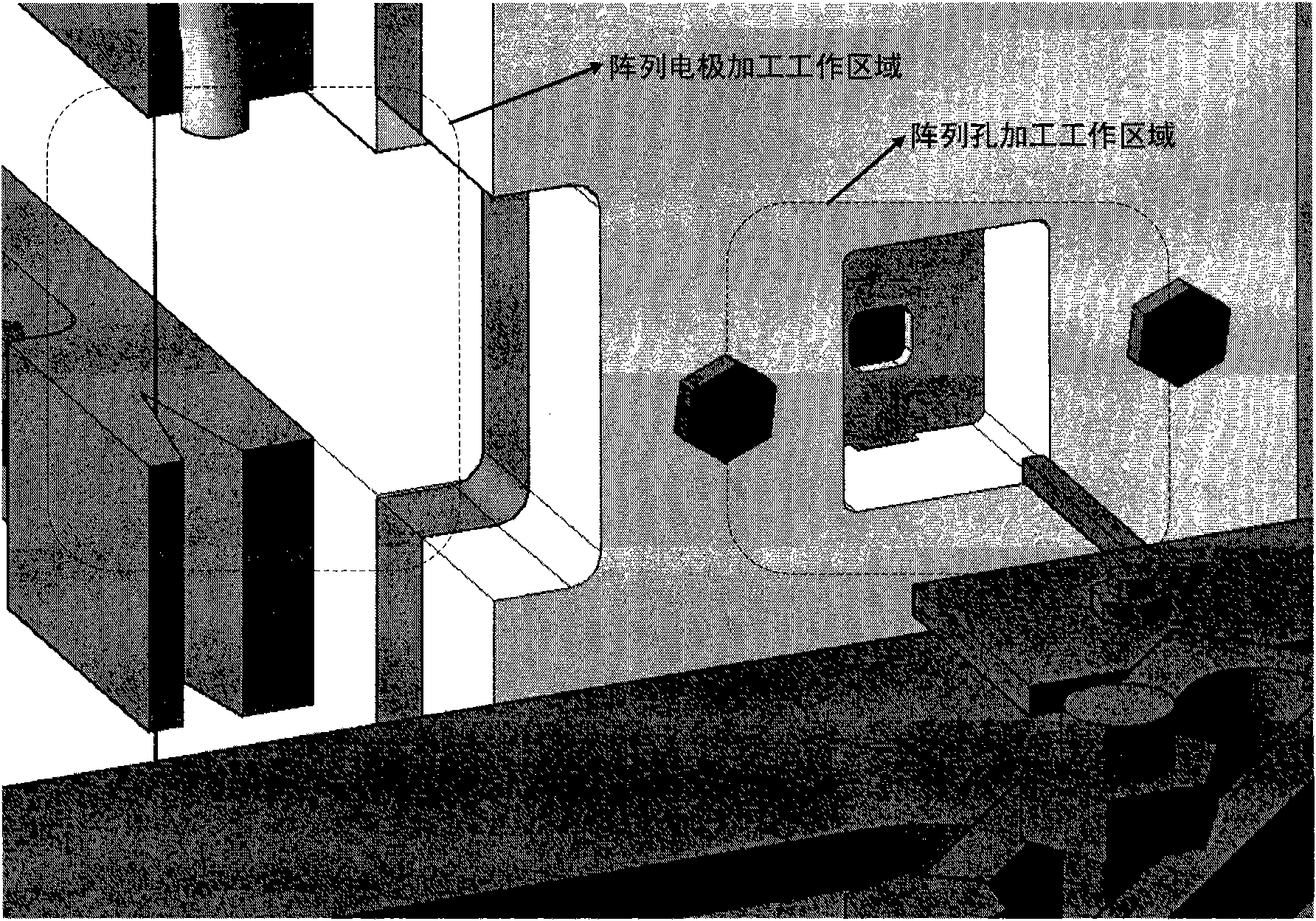

[0016] Such as figure 1 As shown, the special fixture for array holes is installed vertically on the machine tool wire rack, and has sufficient perpendicularity to the X-axis of the machine tool workbench, and sufficient parallelism to the Y-axis; the special fixture for array electrodes is installed horizontally on the machine tool workbench. Driven by the worktable, it can move in the X and Y directions near the machine tool wire electrode and the array hole workpiece.

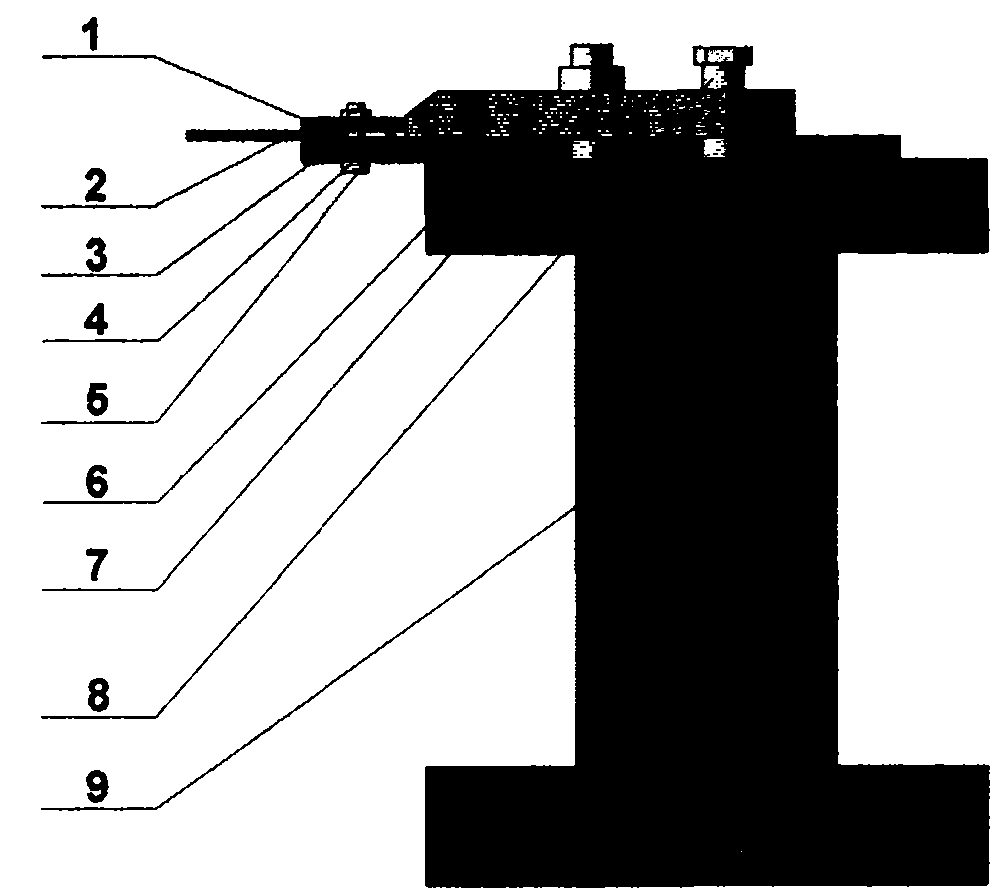

[0017] Such as Figure 1-5 As shown, the array electrode processing fixture is composed of an array electrode square bar clamping mechanism, a fixture fixing mechanism and a support base. The array electrode square bar clamping mechanism includes an upper fixing plate 1, an L-shaped lower fixing plate 3, fastening screws and nuts 4 and the adjustment block 5, the fixture fixing mechanism includes a fastening plate 6, a plate bolt nut 7 and a pre-tightening bolt 8, and the supporting base is a marble support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com