Drum-type material drying device and using method thereof

A drying device and drum-type technology, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of inability to use hot water heat energy in the cooling water tank of the granulator and high energy consumption of the drying equipment, and achieve small damage, Good consistency and low speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

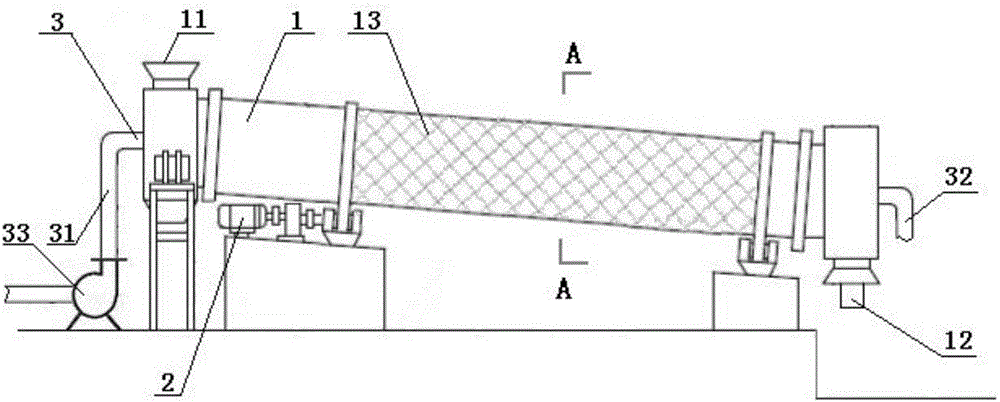

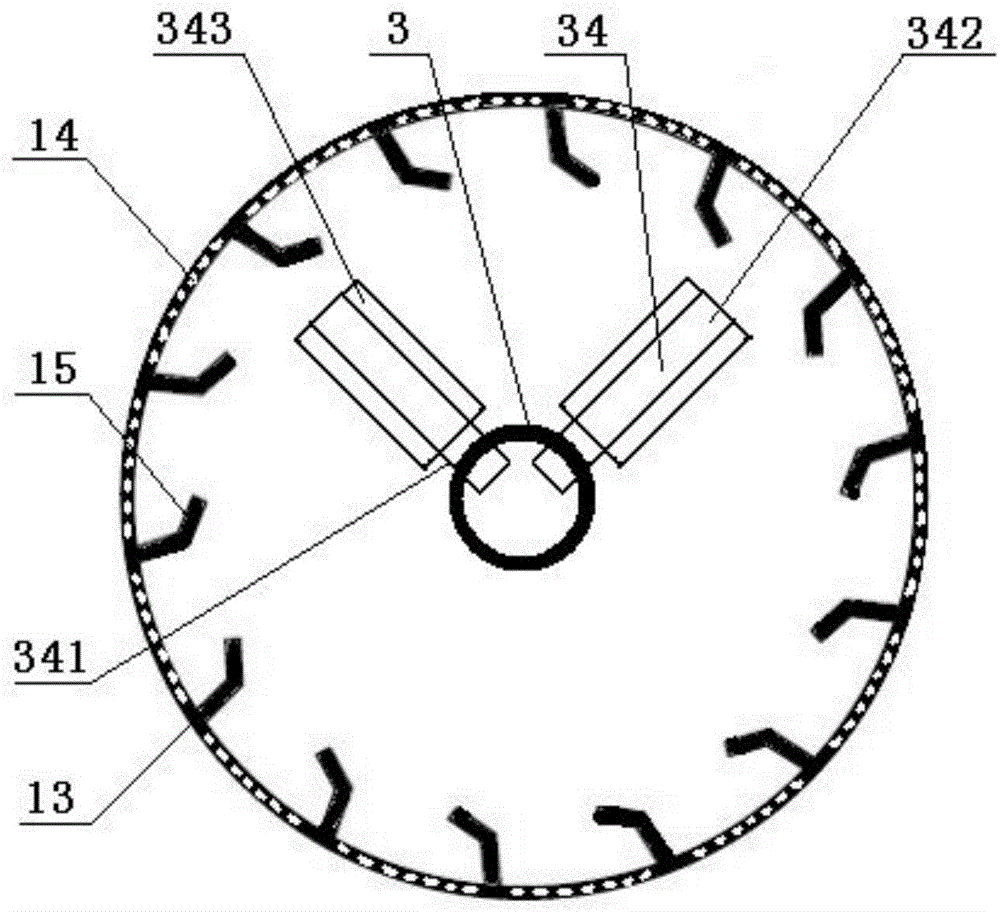

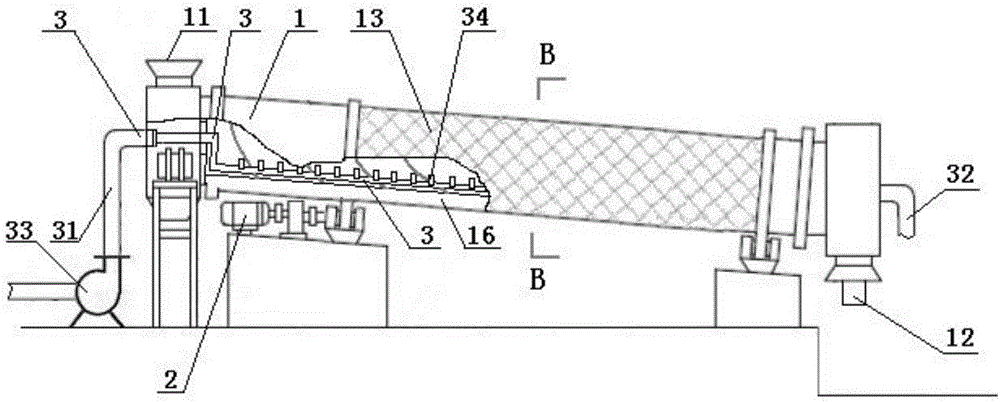

[0042] see figure 1 , figure 2 , Figure 5 , a drum-type material drying device of the present invention, comprising a rotary drum 1, one end of the rotary drum 1 is provided with a material inlet 11, the other end is provided with a discharge port 12, and the bottom of the rotary drum 1 is provided with a drum support and the driving device 2, a screen section 13 is provided in the length direction of the rotary drum 1, and a hot water pipe 3 runs through the hollow length of the rotary drum 1. Since the hot water pipe 3 is installed in the hollow part of the rotary drum 1, the material entering the inside of the rotary drum 1 is heated by the hot water pipe 3, and the moisture on the outside and inside of the rotary drum 1 will be heated and evaporated. A screen is installed on the rotary drum 1 Section 13 is not only for sievin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com