Antibacterial polypropylene block copolymer and preparation method thereof and modified material containing block copolymer

A technology of block copolymer and antibacterial polypropylene, which is applied in the field of copolymers, can solve the problems of PP matrix resin with great influence on mechanical properties, failure, and easy surface desorption, so as to avoid bacterial or fungal infection and the spread of diseases , huge application prospects and market value, the effect of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Crack 50g of isotactic polypropylene at 350°C under the condition of nitrogen protection to prepare polypropylene with terminal double bonds, and then carry out addition reaction of terminal double bond polypropylene with hydrogen chloride or hydrogen bromide to obtain double-terminal halogen (chlorine or bromine) polypropylene.

[0037] Take 30g of self-made polypropylene with terminal chlorine (or terminal bromine) functionalization, dissolve it in xylene, add CuCl and bipyridine as catalyst and ligand respectively, and add 50ml of acrylic acid. Electromagnetically stirred in a constant temperature oil bath at 100°C for 12 hours, cooled, and filtered. The solid product was extracted with ethanol for 48h and dried for later use.

[0038]Weigh 30g of polypropylene / polyacrylic acid block copolymer (without bactericidal function) and dissolve it in xylene, add 10g of chitosan, and react under reflux for 4h. Cool, filter and dry to prepare polypropylene / polyacrylic acid ...

Embodiment 2

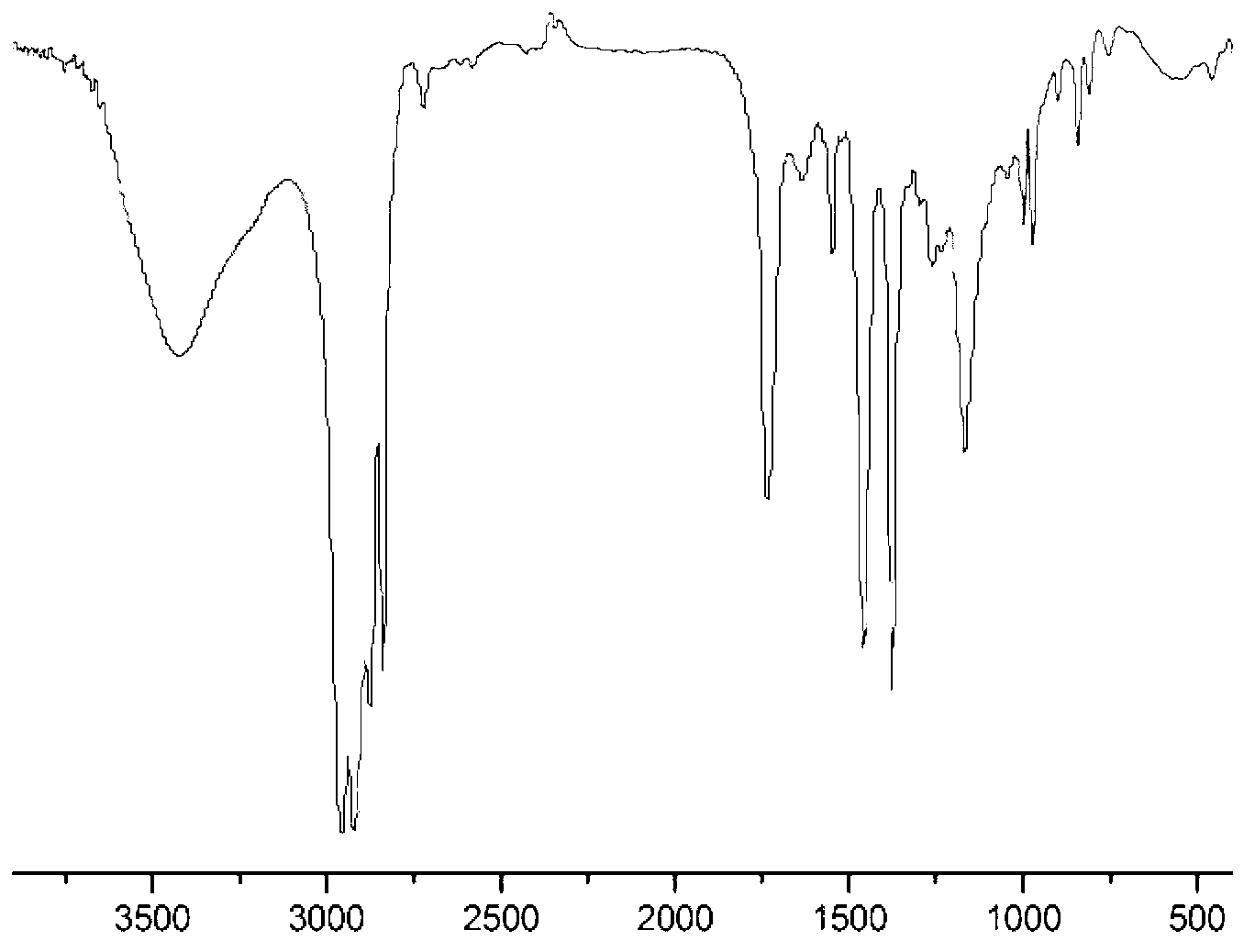

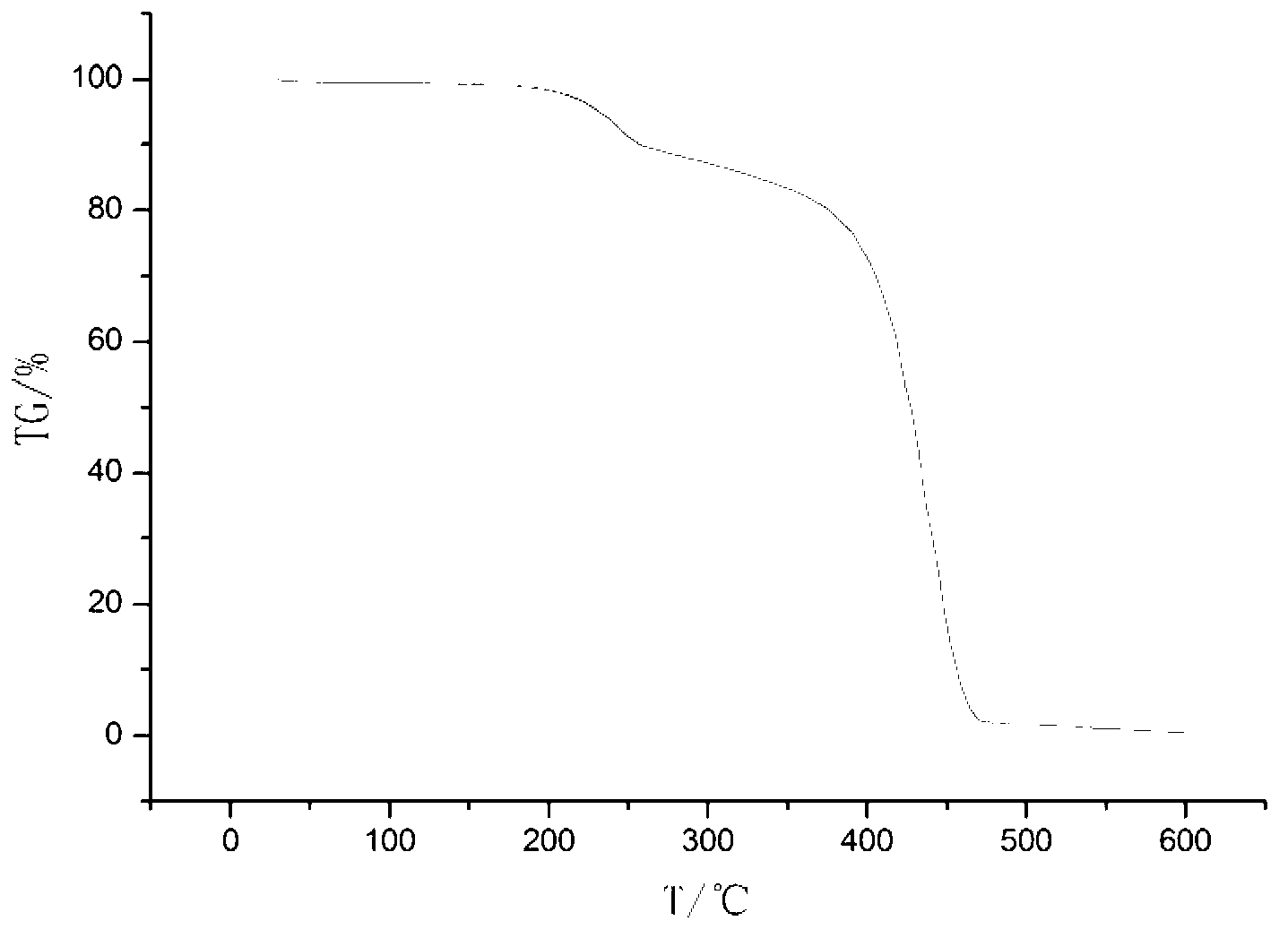

[0042] Take 30g of self-made polypropylene with terminal chlorine functionalization, dissolve it in xylene, add CuCl and bipyridine as catalyst and ligand respectively, and add 10g of p-vinylbenzyl tributylphosphine chloride. Electromagnetically stirred in a constant temperature oil bath at 100°C for 12 hours, cooled, and filtered. The solid product was extracted with ethanol for 48h, and dried to obtain a polypropylene block copolymer containing antibacterial polyvinylbenzyl tributylphosphorous chloride segment (its thermal weight loss diagram is as follows: figure 2 shown).

[0043] The molecular weight of the polypropylene segment in the block copolymer prepared in this embodiment is 4000 g / mol, and the molecular weight of the poly-p-vinylbenzyl tributylphosphorus chloride segment is 5400 g / mol.

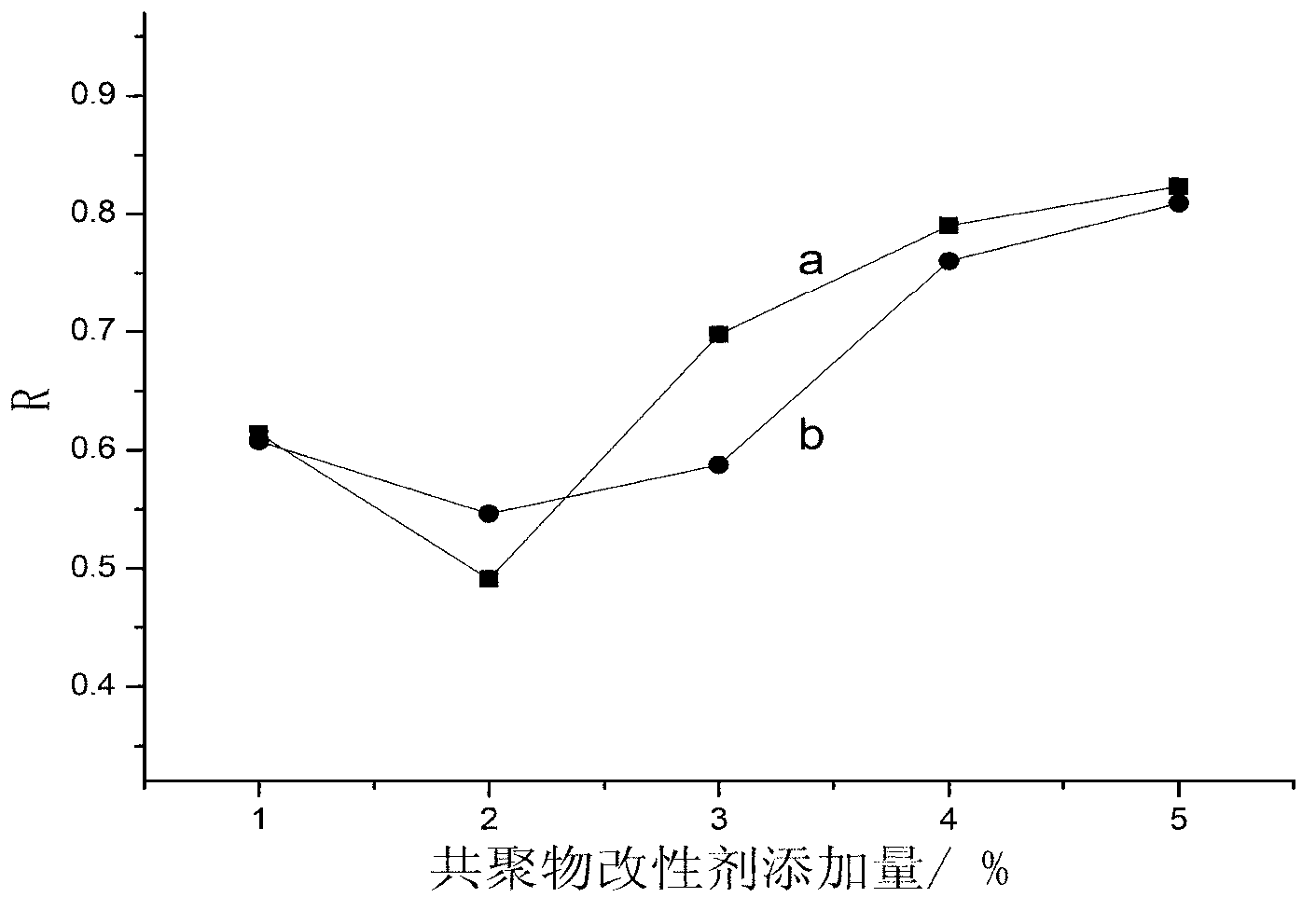

[0044] The above-mentioned synthesized polypropylene block copolymer with antibacterial properties is blended with polypropylene resin to prepare a modified material, and the ad...

Embodiment 3

[0046] Take 30g of self-made polypropylene with terminal chlorine functionalization, dissolve it in xylene, add CuCl and bipyridine as catalyst and ligand respectively, and add 10g of vinylpyridine. Electromagnetically stirred in a constant temperature oil bath at 100°C for 12 hours, cooled, and filtered. The solid product was extracted with ethanol for 48 hours and dried to obtain a polypropylene block copolymer containing polyvinylpyridine segments (no antibacterial properties). The block copolymer is quaternized with dimethyl sulfate to obtain a polypropylene block copolymer (with antibacterial properties) containing polyvinylpyridine quaternary ammonium salt segments.

[0047] The molecular weight of the polypropylene segment in the block copolymer prepared in this embodiment is 7500 g / mol, and the molecular weight of the polyvinylpyridine quaternary ammonium salt segment is 4800 g / mol.

[0048] The above-mentioned synthesized polypropylene block copolymer with antibacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com