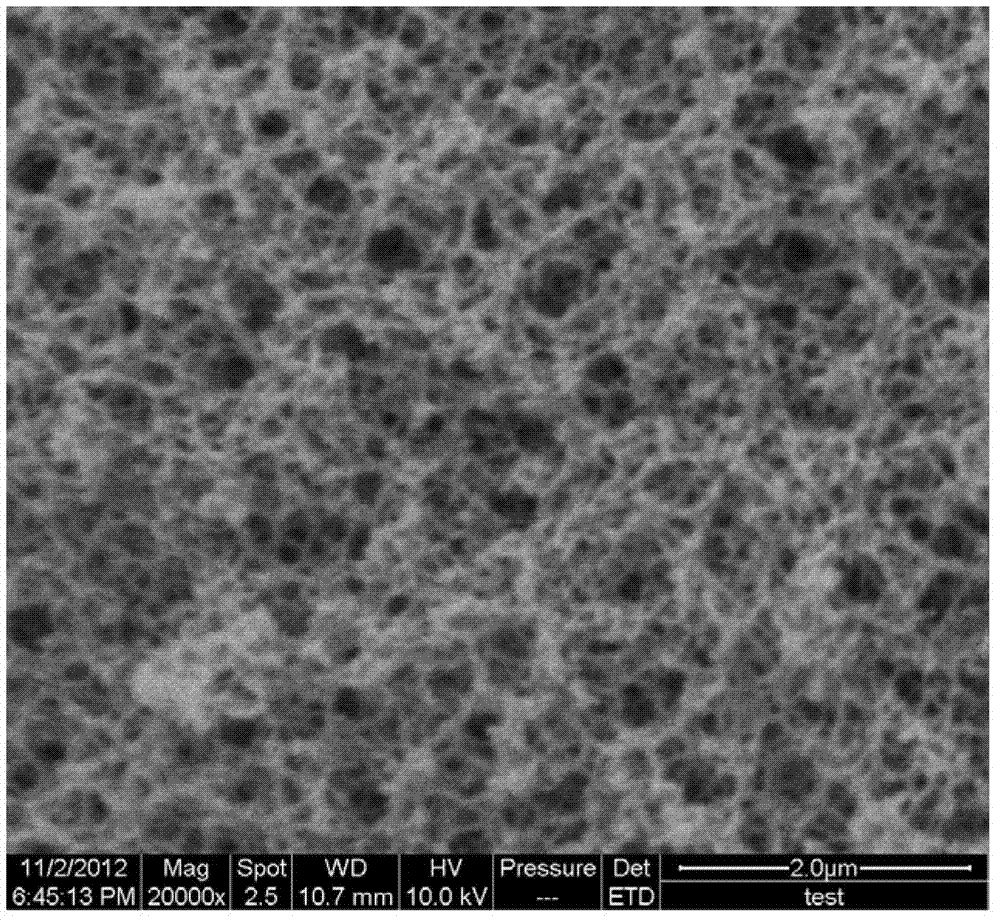

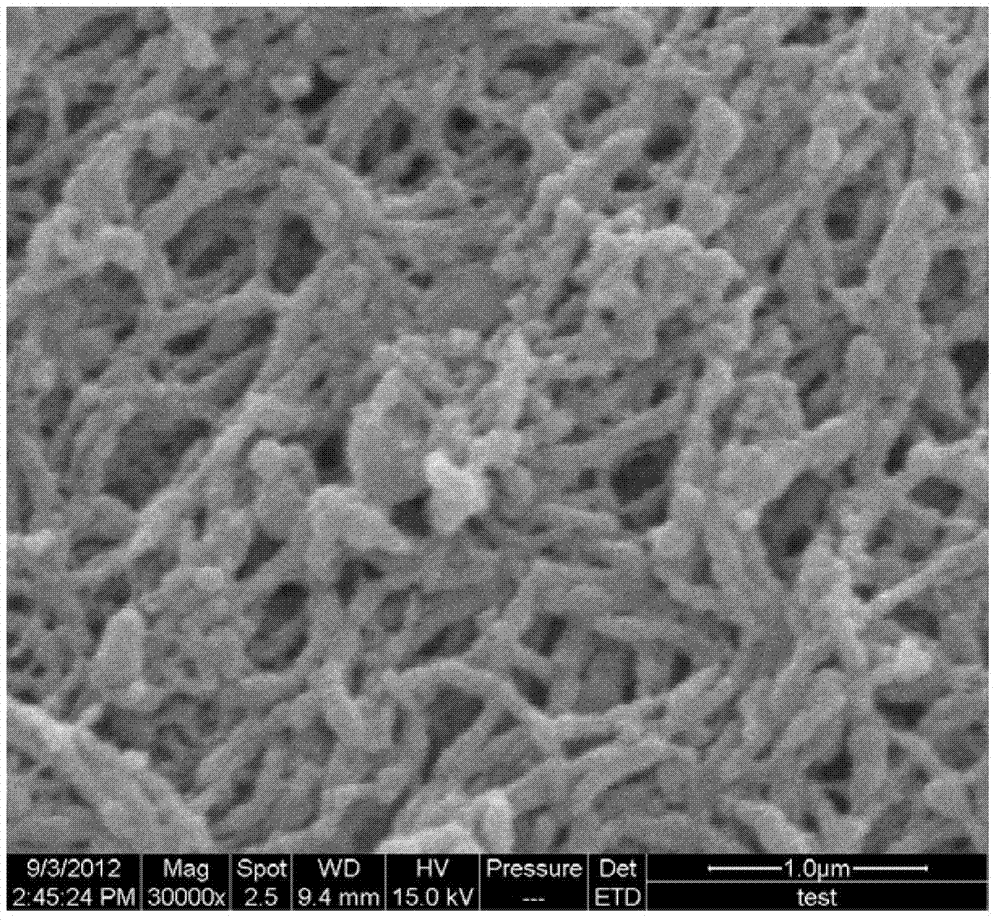

Method for preparing inorganic oxide aerogel by taking biomass nanometer fibrillation cellulose as template

A nanofibrillation, inorganic oxide technology, applied in the preparation of oxide/hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of low yield, complex process, high cost, etc. The effect of low pollution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: This embodiment is a method for preparing inorganic oxide aerogels using biomass nanofibrillated cellulose as a template, specifically as follows:

[0015] 1. Preparation of biomass nanofibrillated cellulose aqueous solution: ①. Firstly, crush the raw material of biomass nanofibrillated cellulose to obtain 60-80 mesh biomass powder, and then process 60-80 mesh biomass powder Extract and remove the extract to obtain a light yellow solid; ②, first dissolve sodium chlorite in deionized water, and then adjust the pH value to 4-5 with glacial acetic acid to obtain chlorite with a pH value of 4-5 Sodium chlorite solution; ③, immerse the light yellow solid obtained in step 1 into the sodium chlorite solution with a pH value of 4 to 5 obtained in step 2, and soak at a temperature of 75°C to 80°C until the light yellow solid turns into until it becomes a white solid, take out and obtain hemcellulose; ④, immerse the hemcellulose obtained in step 1 and ③ in ...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the raw material of biomass nanofibrillated cellulose described in step ① is forest waste, cotton, hemp, animal hair, waste silk, spider silk, bamboo, straw or bagasse. Others are the same as the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Soxhlet extraction described in step one ① described in step one ① is carried out as follows: the 60~80 mesh raw Put the substance powder into a Soxhlet extractor, and use benzene / ethanol solution to extract at a temperature of 80°C to 95°C for 5h to 7h to obtain a light yellow solid; It is made by mixing benzene and absolute ethanol at a volume ratio of 2:1. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com