Patents

Literature

55results about How to "Improve release quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete releasing agent for aluminum alloy template of building

InactiveCN104629885ABlock penetration throughAvoid destructionCeramic shaping apparatusLubricant compositionMonoglycerideDiglyceride

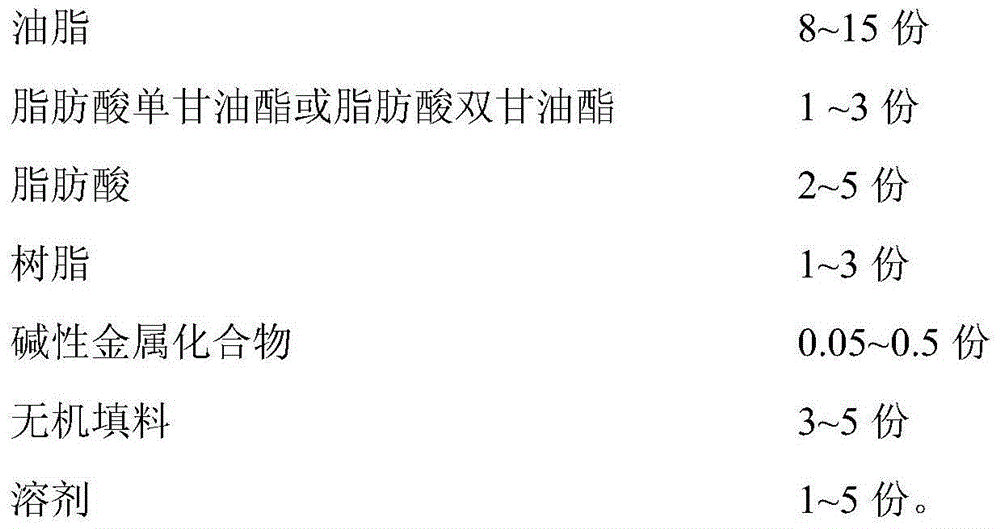

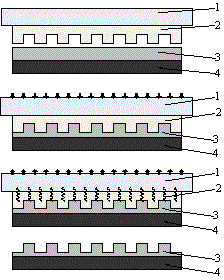

The invention provides a concrete releasing agent for an aluminum alloy template of a building. The releasing agent comprises the following components in parts by weight: 8-15 parts of grease, 1-3 parts of fatty acid monoglyceride or fatty acid diglyceride, 2-5 parts of fatty acid, 1-3 parts of resin, 0.05-0.5 parts of basic metal compound, 3-5 parts of inorganic filler and 1-5 parts of solvent. The releasing agent coats the aluminum alloy template of the building and is used in the concrete pouring technology, the concrete releasing quality is good without obvious blister, and the releasing agent residue surface matter is easily removed and the releasing agent is suitable for use for single or multiple times, and the service life of the template is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

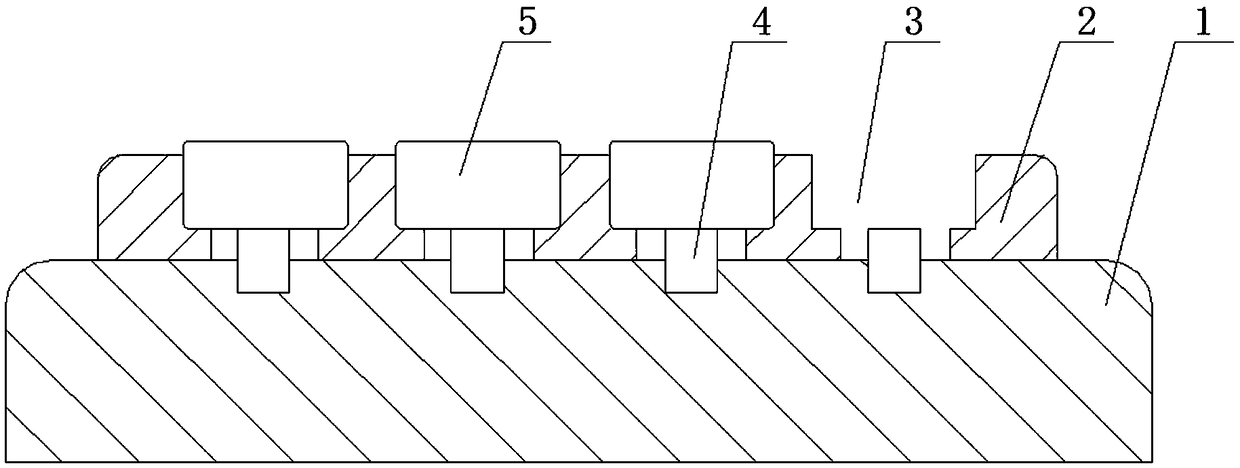

Demolding method in nanoimprint technology process

InactiveCN105319838AImprove release qualityReduce release forcePhotomechanical apparatusAdhesive materialsComposite material

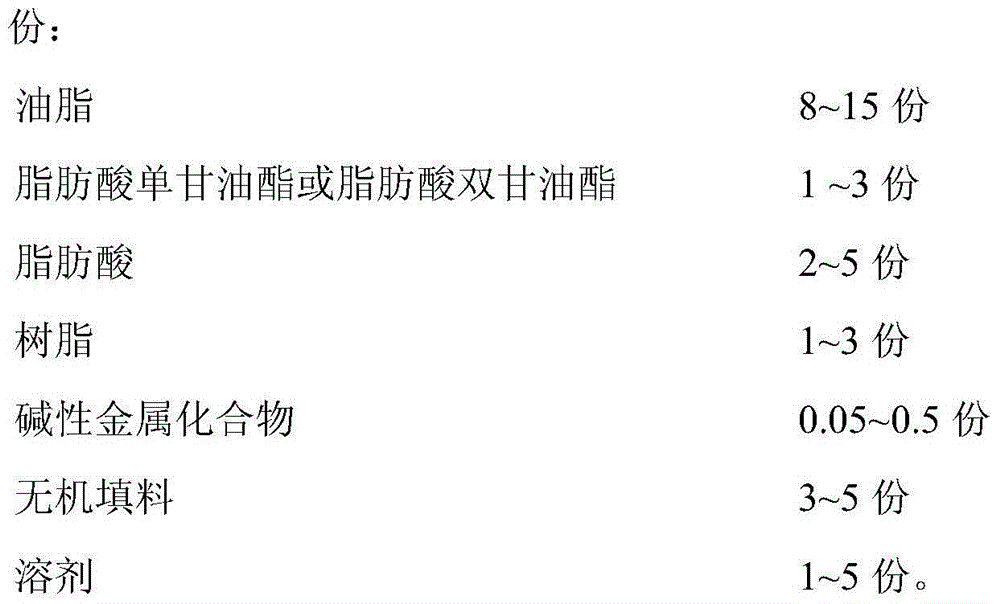

The invention discloses a demolding method in a nanoimprint technology process. The demolding method comprises the following steps: firstly, coating a substrate with a nanoimprint adhesive material to form an imprint adhesive layer; secondly, pressing a template into the imprint adhesive layer; thirdly, transmitting an ultrasonic wave to the template by an ultrasonic transmitting device at the upper part of the template after the imprint adhesive layer is cured and fixed, so as to assist separation of the template and the imprint adhesive layer; and finally removing the template and finishing the demolding process. Compared with the prior art, the problems that the molded nanoimprint structure is serious in deformation, overlarge in tear force and demolding force and the like due to cohesion force of the template and the adhesive layer in the demolding process of a nanoimprint technology are solved; imprinted pattern transferring and photoetching are completely consistent; the demolding force is effectively reduced; the demolding success rate is greatly improved; and large-scale industrial production is realized.

Owner:SHANDONG UNIV OF SCI & TECH

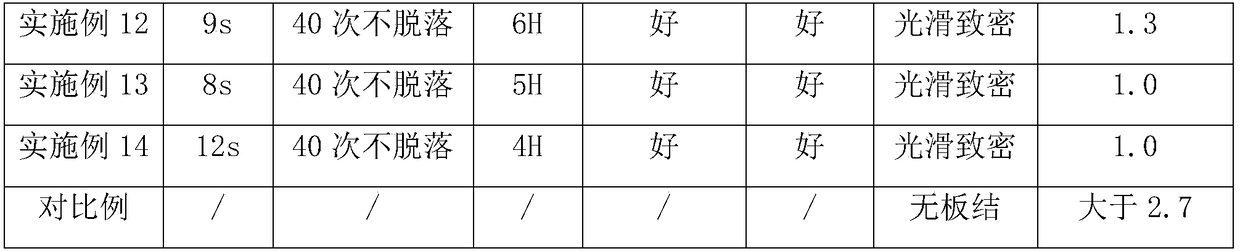

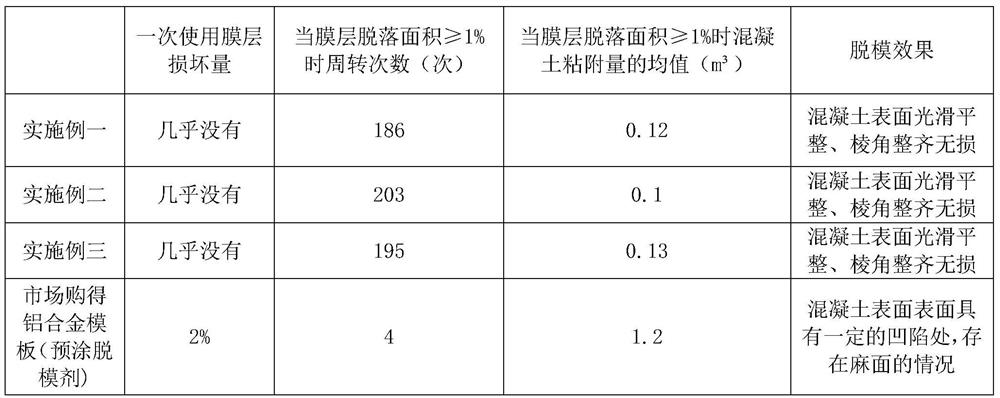

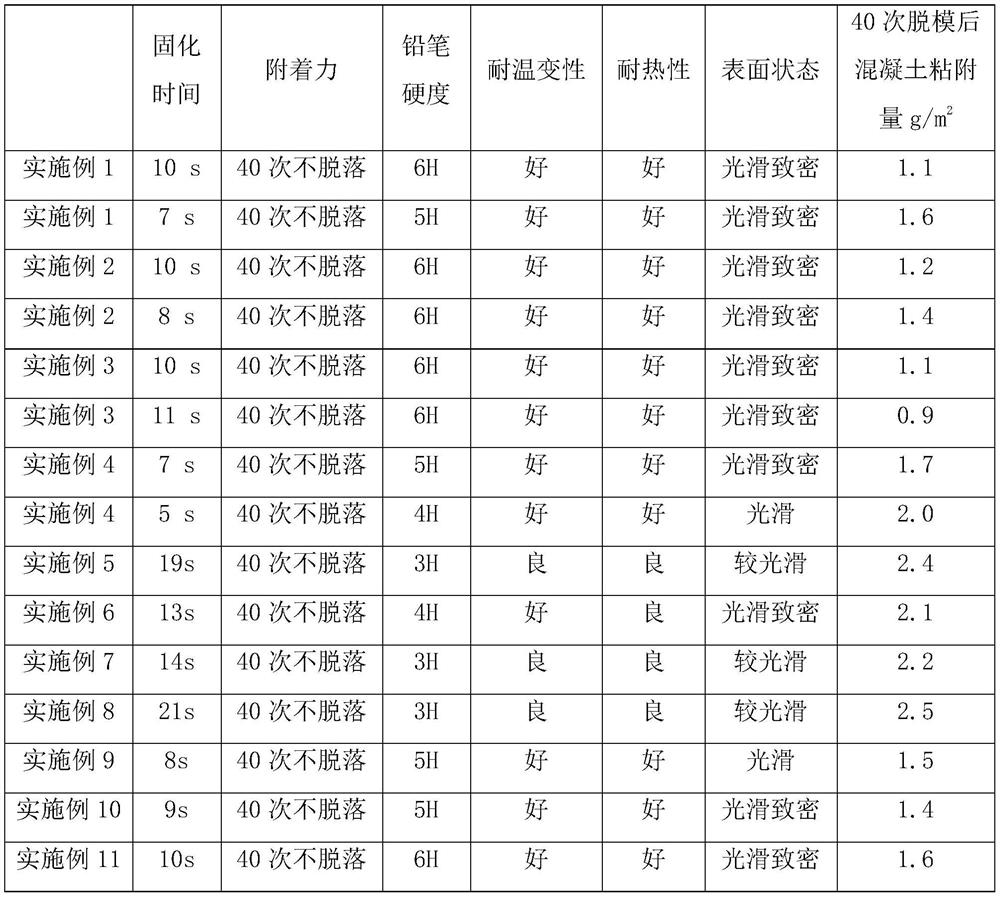

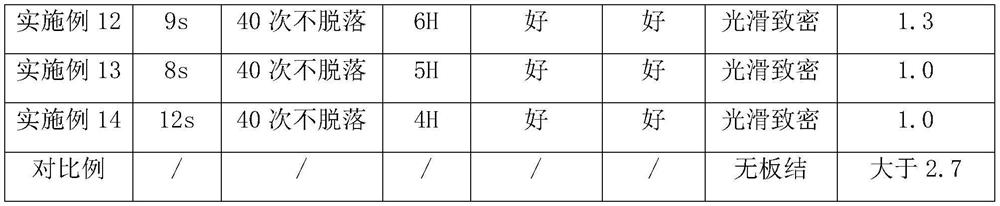

Ultraviolet-cured aluminum formwork release agent with high number of turnover times and preparation method of ultraviolet-cured aluminum formwork release agent

ActiveCN109401560AReduce pollutionNo pollution in the processEpoxy resin coatingsUltravioletDiglycidyl ether

The invention provides an ultraviolet-cured aluminum formwork release agent with the high number of turnover times and further provides a preparation method of the release agent. The ultraviolet-curedaluminum formwork release agent is prepared from the following components in parts by weight: 6-10 parts of modified acrylic acid epoxy resin, 1-3 parts of a UV monomer diluent, 0.1-0.6 part of an adhesion promoter, 0.1-0.6 part of a leveling agent, 0.1-0.4 part of a surface slip agent and 0.3-0.9 part of an ultraviolet initiator, wherein the modified acrylic acid epoxy resin is prepared from oneor more of acrylic acid, hydroxyethyl acrylate, isophthalic acid, phthalic anhydride, trimellitic anhydride, glycol diglycidyl ether and epichlorohydrin in a modified mode. An aluminum formwork is coated with the release agent, the release agent is subjected to ultraviolet irradiation at the room temperature and thus cured into a film, the release agent is used for a concrete pouring process, therelease quality of concrete is good, the surface is smooth and free of pollution, the surface of the formwork is free of concrete residue, after being brushed with the release agent once, the formwork can be used in a turnover mode by 100 times, and thus the service life of the formwork is prolonged.

Owner:HUNAN HUITIAN HIGH MOLECULAR TECH CO LTD

Demolding device for injection molding production of daily necessities and using method thereof

Owner:苏州锦坤模塑有限公司

Multi-major-element high-entropy alloy and preparation method thereof

InactiveCN105950943AImprove corrosion resistanceIncrease mixing entropyTransportation and packagingMetal-working apparatusHigh entropy alloysHardness

The invention discloses multi-major-element high-entropy alloy and a preparation method thereof and belongs to the technical field of alloy materials. Through the excellent comprehensive performance of the high-entropy alloy, the problem that existing metal is poor in strength, hardness, compactness, corrosion resistance and the like is mainly solved. Elements such as V, Zr, Hf, Ti, Cr, Zr and Mn are configured according to the equal molar ratio or the approximate equal molar ratio, and VZrHfTiCrZrMn alloy is obtained through vacuum sintering. The alloy has the characteristics of being high in strength and hardness and excellent in comprehensive performance, and the alloy can be used for special alloy, die manufacturing, special tools and the like. According to the multi-major-element high-entropy alloy and the preparation method thereof, the thought is clear, operation is easy, the practicability is high, and the obtained alloy product has certain market prospects.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

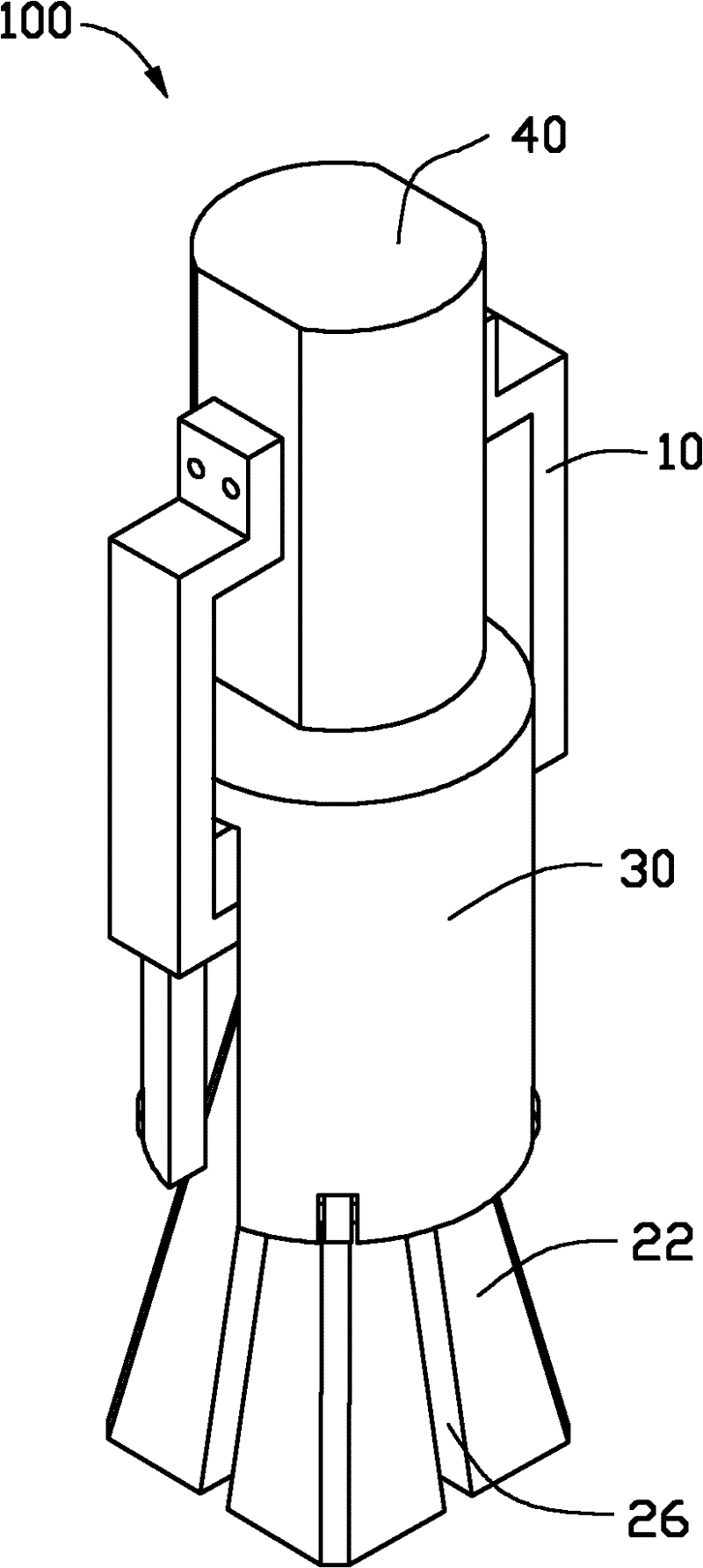

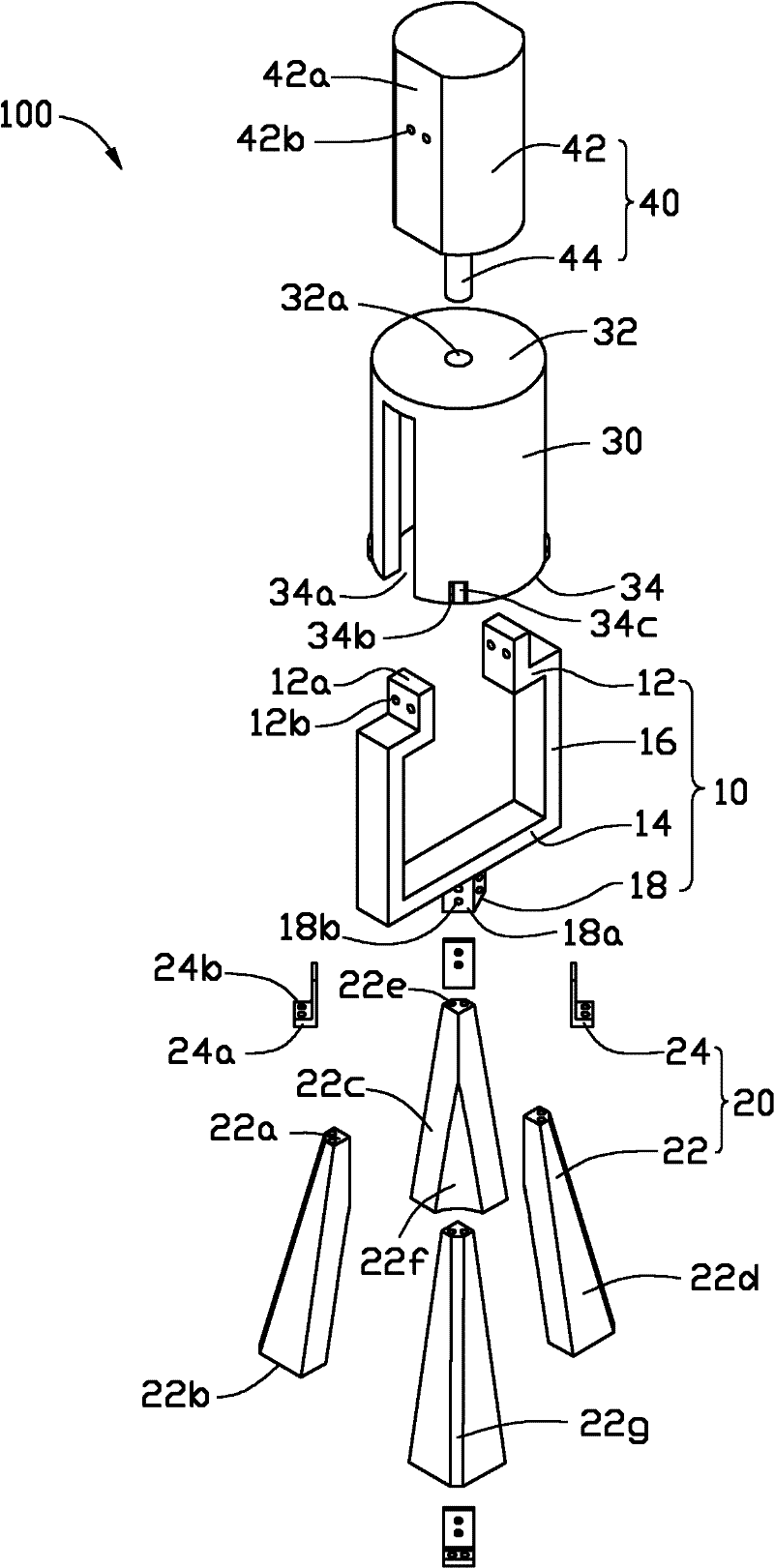

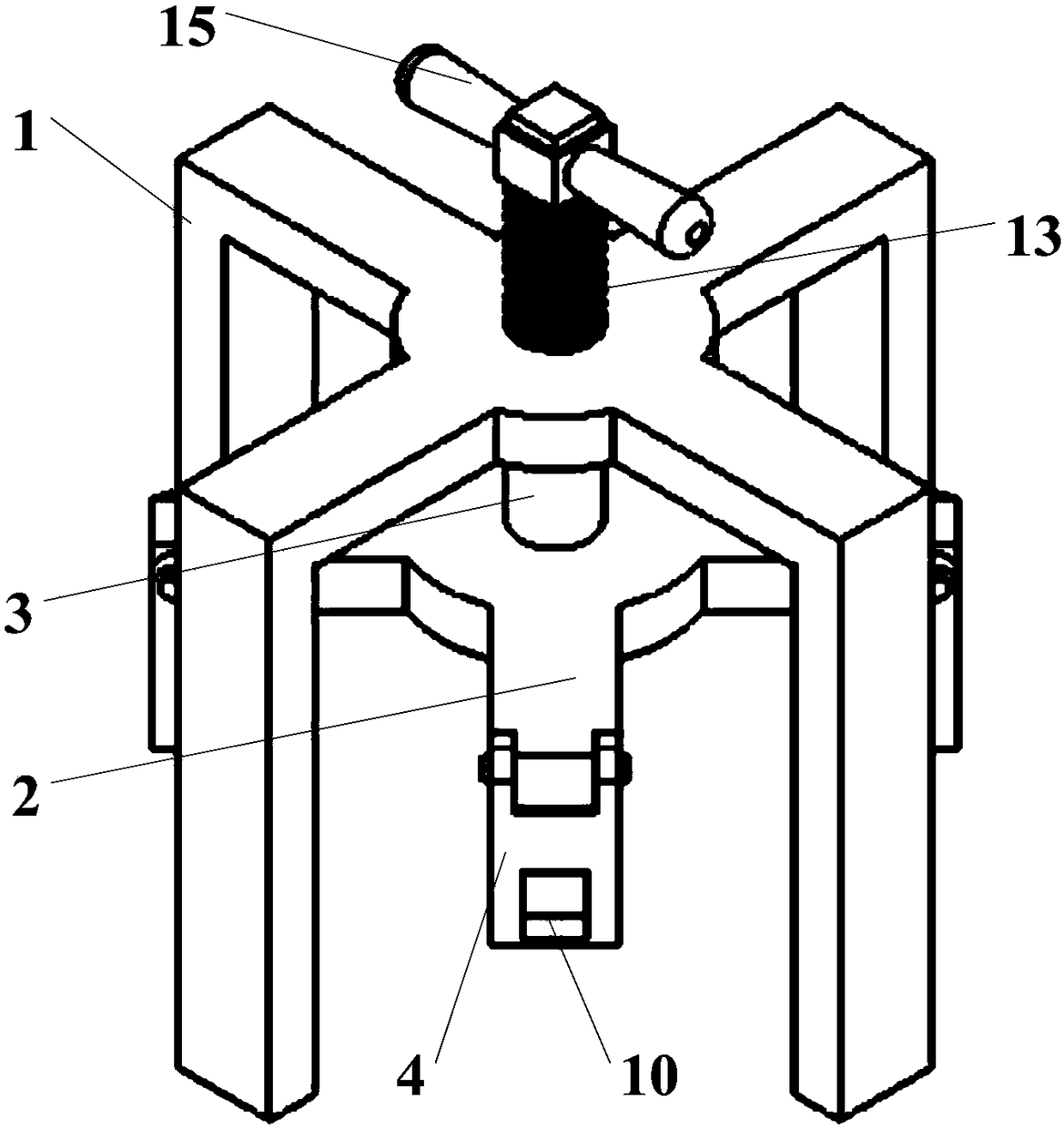

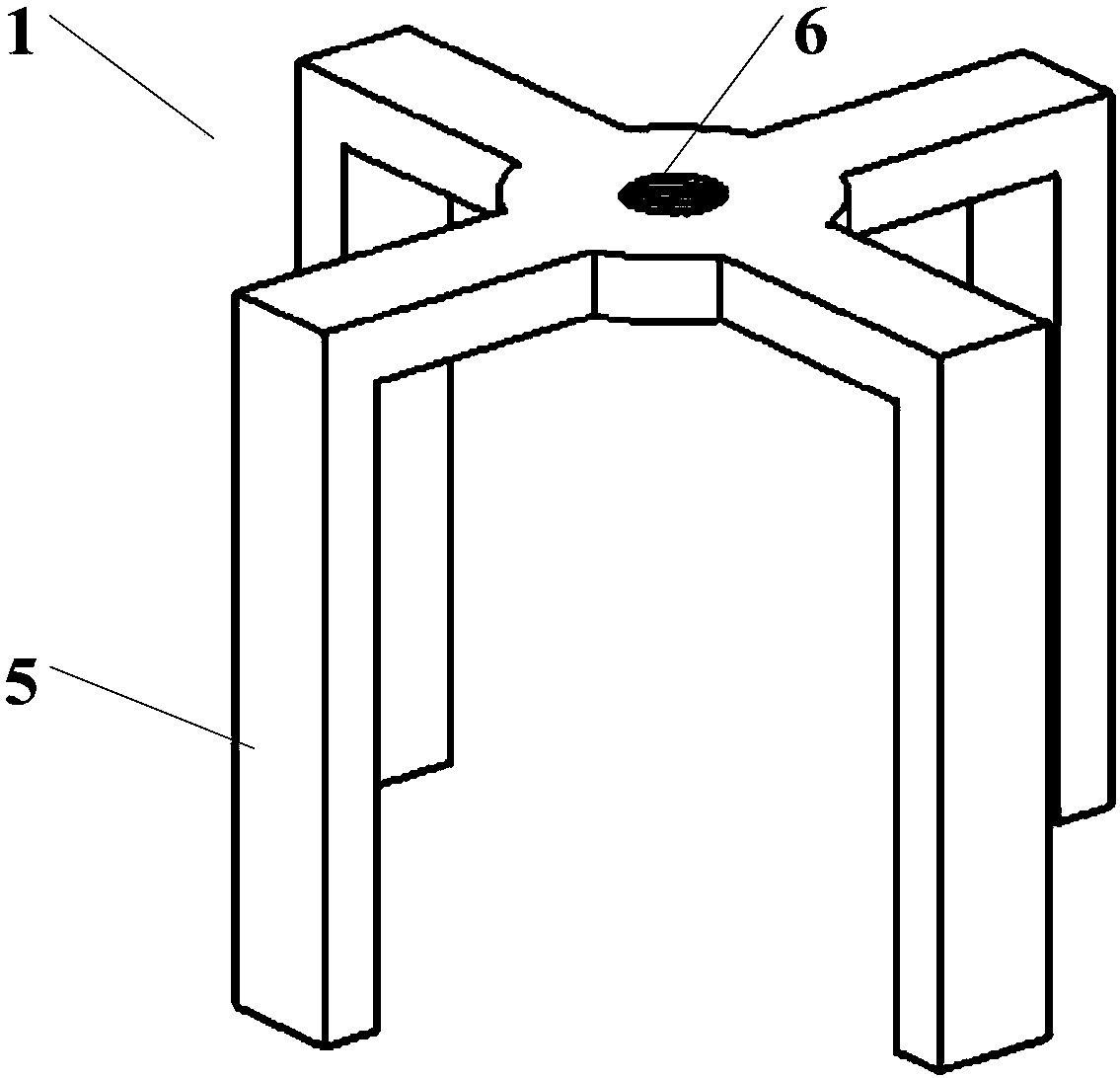

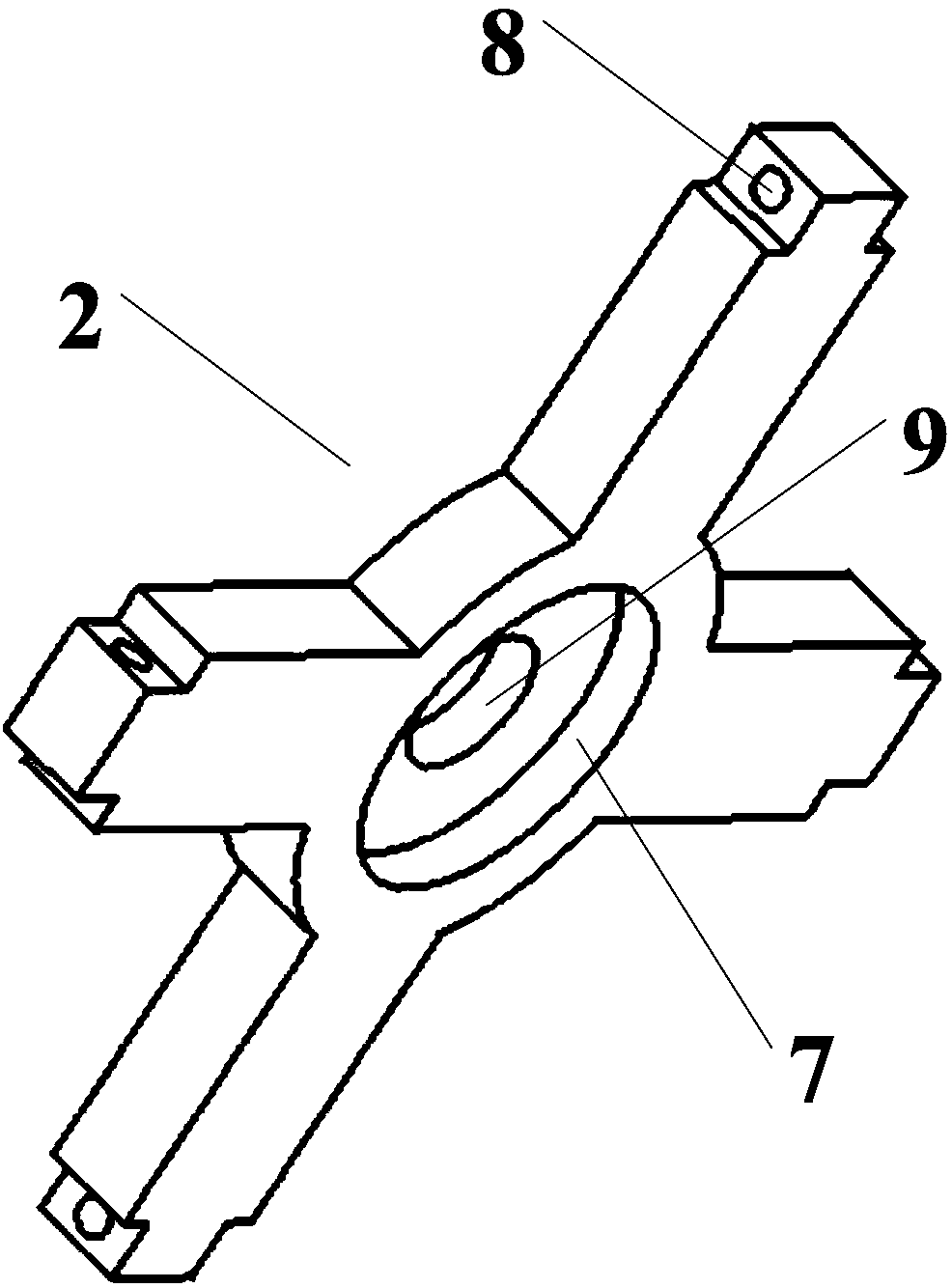

Gripper

The invention provides a gripping device for clamping and taking out multicavity injected shaped parts. The shaped part comprises a material rod and a connecting rod formed by extended ends of a plurality of material rods. The gripping device comprises a fixed framework, a plurality of gripping jaws, a sleeve and a linear drive unit. Each gripping jaw comprises a gripping jaw body and an elastic element which fixes the gripping jaw body on the fixed framework. The plurality of gripping jaw bodies are distributed in a bunchy shape. A gap for accommodating a corresponding connecting rod is located between every two adjacent gripping jaw bodies. The sleeve is sleeved around the gripping jaw bodies from the end where a plurality of elastic elements are located, and constrains the gripping jaw bodies. The linear drive unit is fixed on the fixed framework for driving the sleeve to move towards a direction far from the elastic elements and to reset. The gripping device provided in the invention clamps and takes out shaped parts through a plurality of connecting rods so as to realize demoulding, which enables deformation or fracture of the connecting rods to be avoided and quality of demoulding to be improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shaft sleeve material and preparation method

The invention discloses a shaft sleeve material and a preparation method. A shaft sleeve is manufactured through the following process steps of raw material preparation, pretreatment, powder mixing, preliminary molding, high-temperature sinter molding, heat treatment and the like. The shaft sleeve material is prepared from, by mass, 1-2% of silicon dioxide, 0.5-1.2% of manganese dioxide, 0.5-1.6% of molybdenum disulfide, 0.5-2% of lanthanum oxide, 0.2-0.9% of nickel oxide, 0.5-1.2% of cobalt carbide, 1-2% of silicon carbide, 0.3-1% of graphite, 0.2-0.8% of wax micro-powder, 0.2-0.8% of chromium, 1.5-3% of tin, 2-10% of copper, 0.1-0.5% of phosphorus, 0.1-0.5% of zirconium and the balance iron and inevitable impurities. The produced shaft sleeve material has high wear resistance and hardness as well as high strength and impact resistance.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

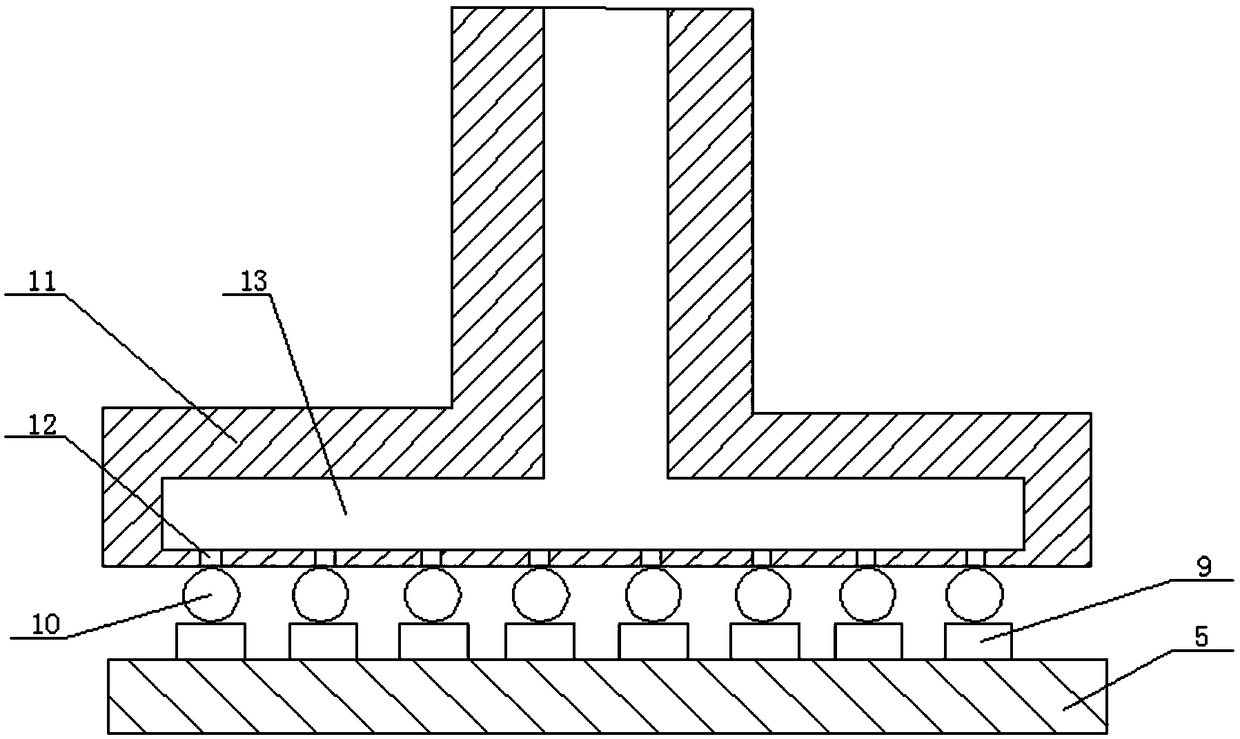

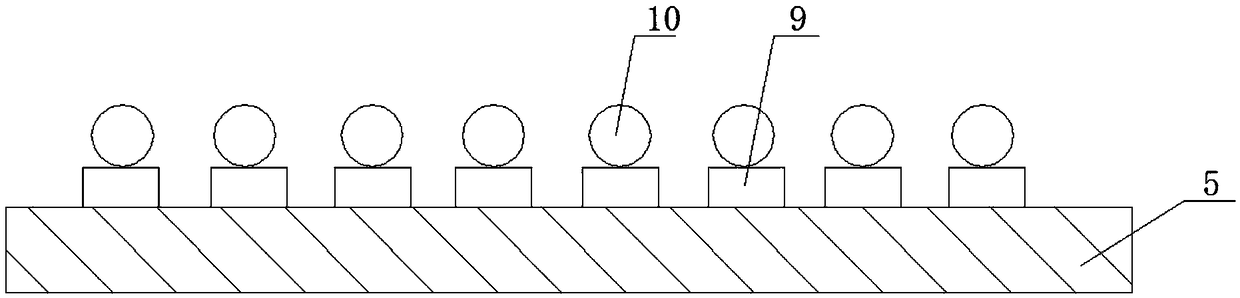

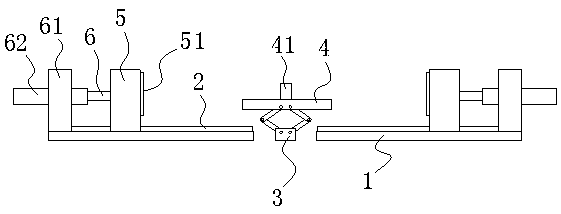

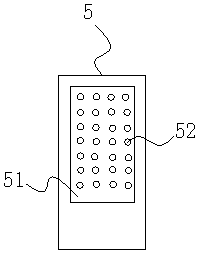

BGA ball planting device and method

InactiveCN108966525AQuick recyclingReduce scrap ratePrinted circuit assemblingEngineeringPrinting press

The invention discloses a BGA (Ball Grid Array) ball planting device and method, which belong to the technical field of BGA ball planting. The device comprises a printer and a laminator. The printer is provided with a printing fixture which includes a supporting base. The supporting base is provided with a supporting carrier which is connected with the supporting base. The supporting carrier is provided with multiple grooves, and the cross sections of the grooves in the vertical direction are in an inverted convex shape. The laminator comprises a ball planting fixture I which includes a suction nozzle II. The cross section of the suction nozzle II in the vertical direction is convex. The suction nozzle II is of a hollow structure inside, and is provided with multiple small holes in the lower surface thereof. The small holes are communicated with the hollow structure, and are evenly distributed on the lower surface of the suction nozzle. The method comprises the following steps: (1) tinremoving; (2) cleaning; (3) printing; (4) ball planting; and (5) reflow soldering. BGA components can be quickly recovered and utilized, the scrap rate of parts is reduced, and the effect of cost reducing is achieved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

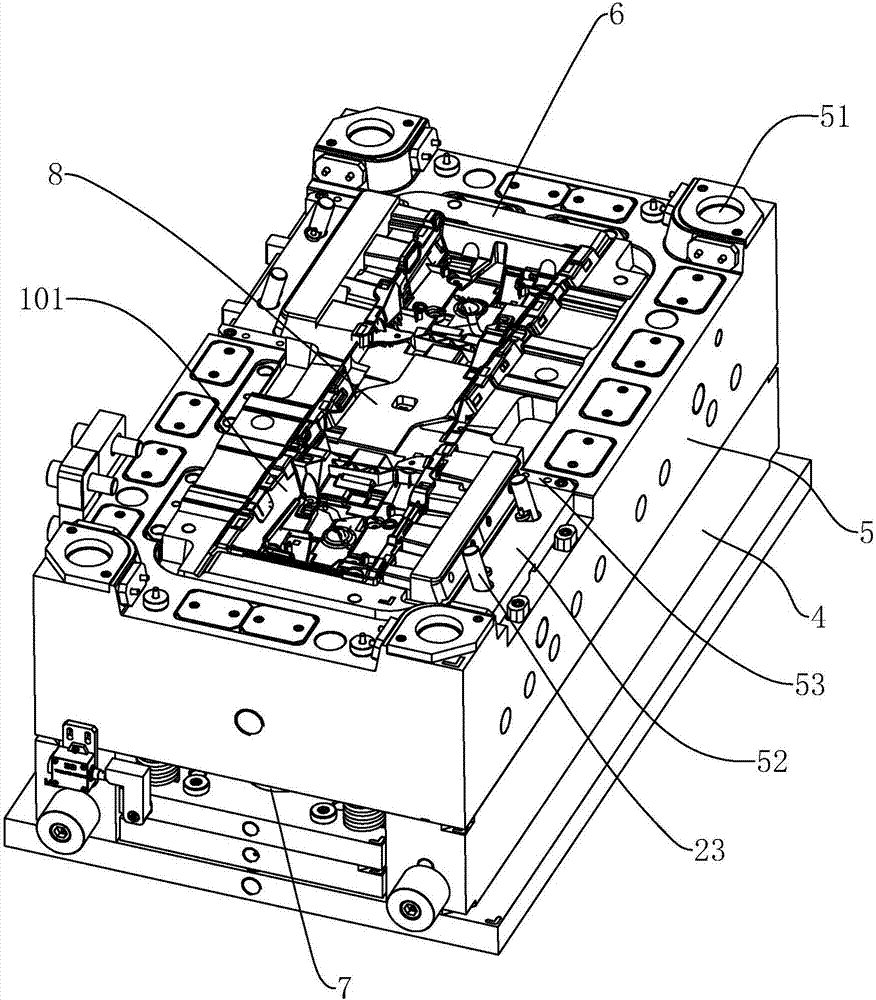

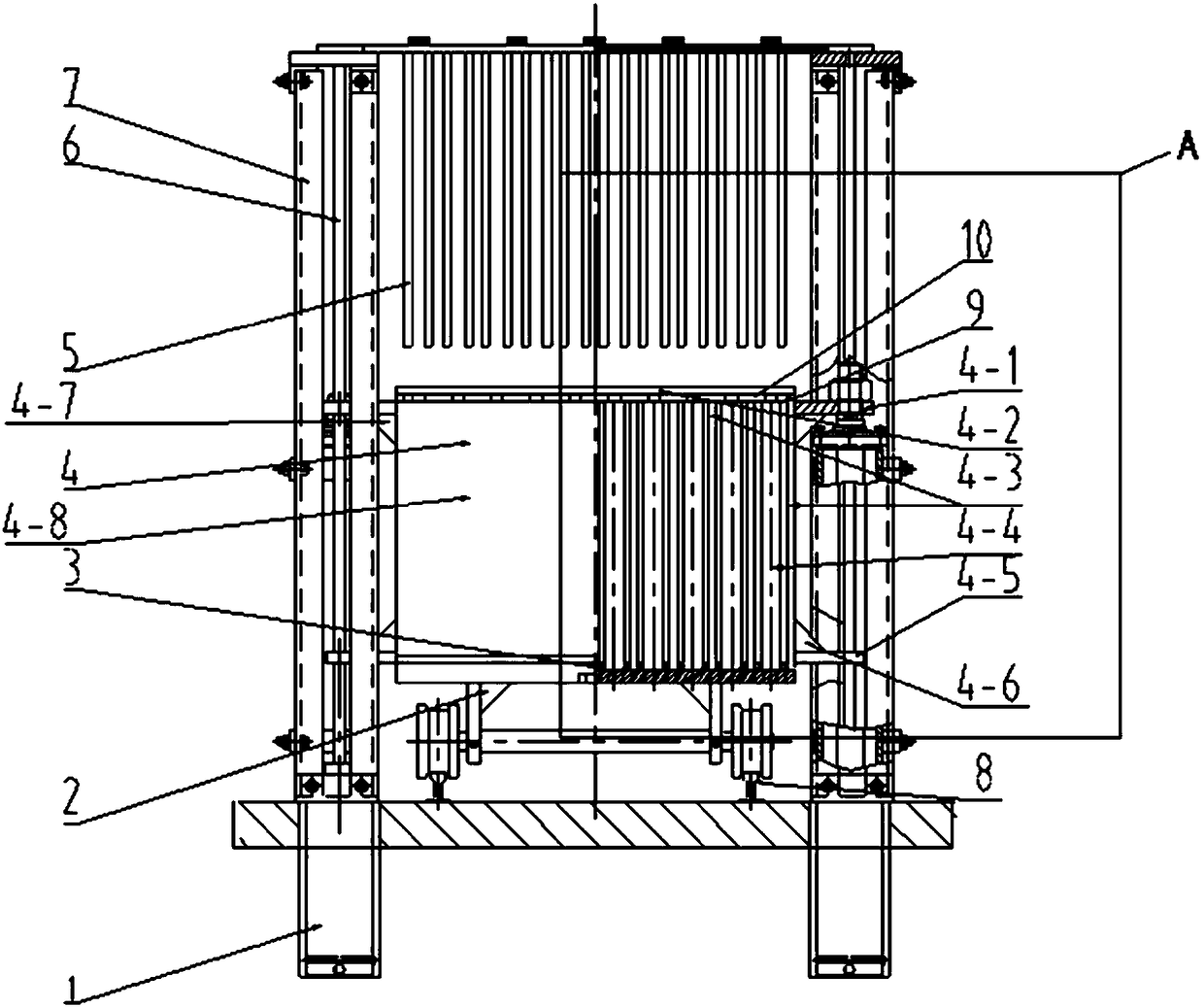

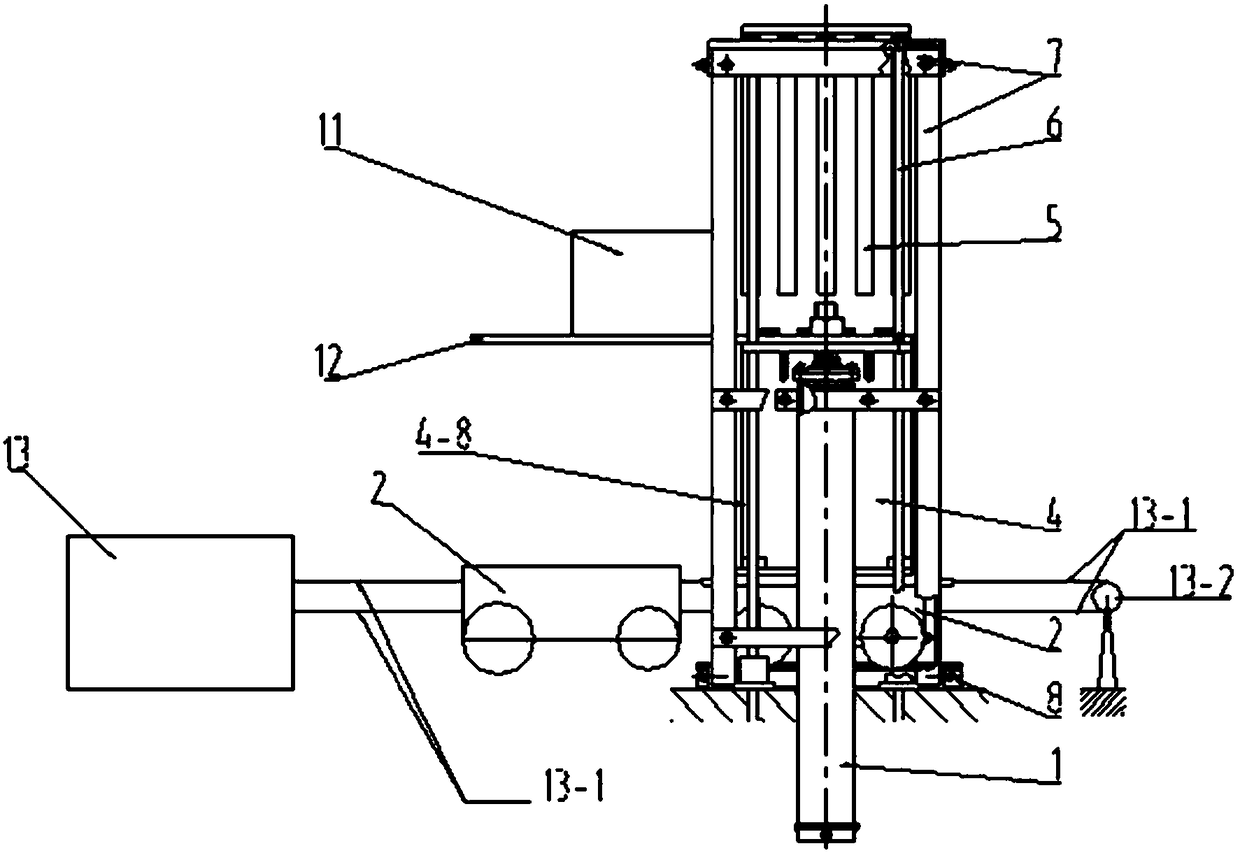

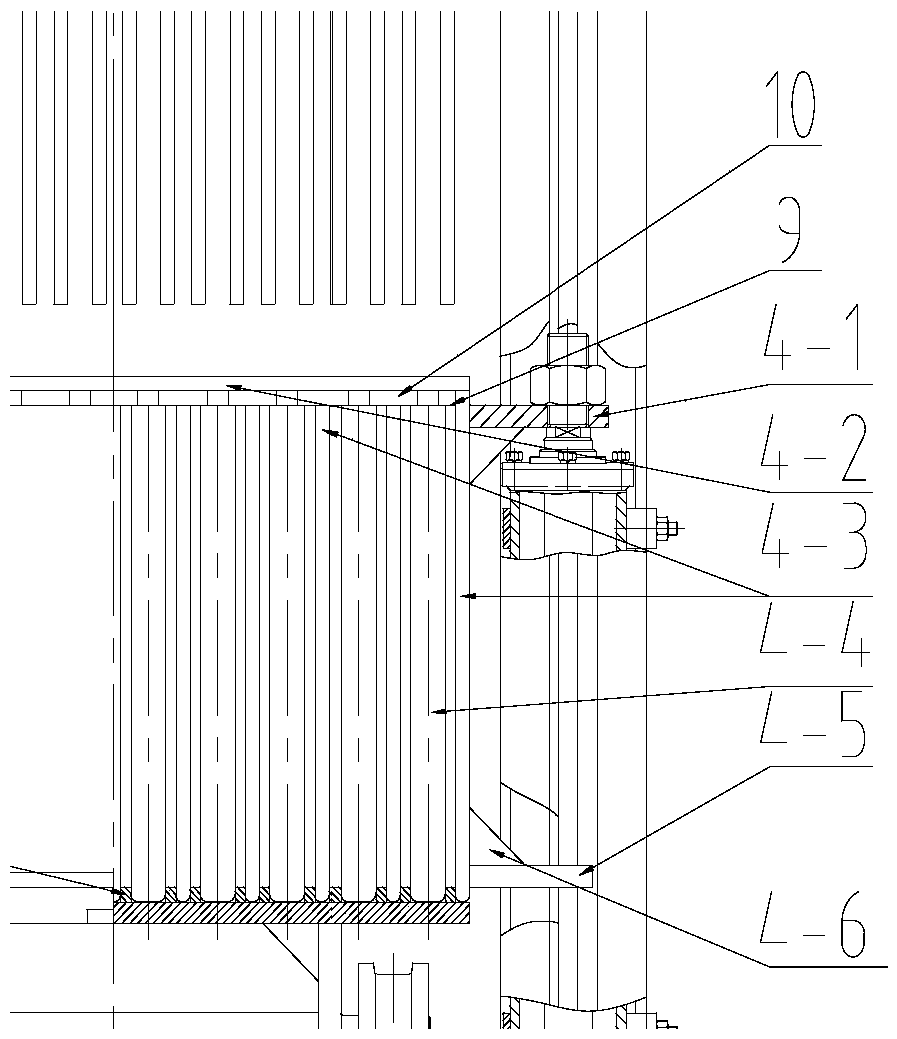

Forming mold for auxiliary instrument middle mounting support

The invention discloses a forming mold for an auxiliary instrument middle mounting support. The forming mold comprises a fixed mold seat plate, a fixed mold plate, an upper mold core, a movable mold seat plate, a movable mold plate, a lower mold core, a driving device, a forming column, a vertical male mold insert, a hook face male mold insert, a side wall male mold insert, a forming male mold insert and a forming female mold insert. The fixed mold plate is provided with a guiding column, and the movable mold plate is slidably provided with a sliding block. The guiding column is arranged in the sliding block in a penetrating mode, the tail end of the guiding column is inserted in the movable mold plate and slidably connected with the movable mold plate, and an orientation assembly is arranged between the sliding block and the movable mold plate. A first punching male mold, a second punching male mold, a third punching male mold and a fourth punching male mold are connected to the sliding block. The forming column, the vertical male mold insert, the hook face male mold insert, the side wall male mold insert, the forming male mold insert, the forming female mold insert, the upper mold core and the lower mold core form the cavity wall of a model cavity. The auxiliary instrument middle mounting support is formed through integrated injection molding, the workpiece surface evenness of the auxiliary instrument middle mounting support is improved, and thus the forming quality of the auxiliary instrument middle mounting support of the middle of an auxiliary instrument is improved.

Owner:宁波斯穆汽车模具有限公司

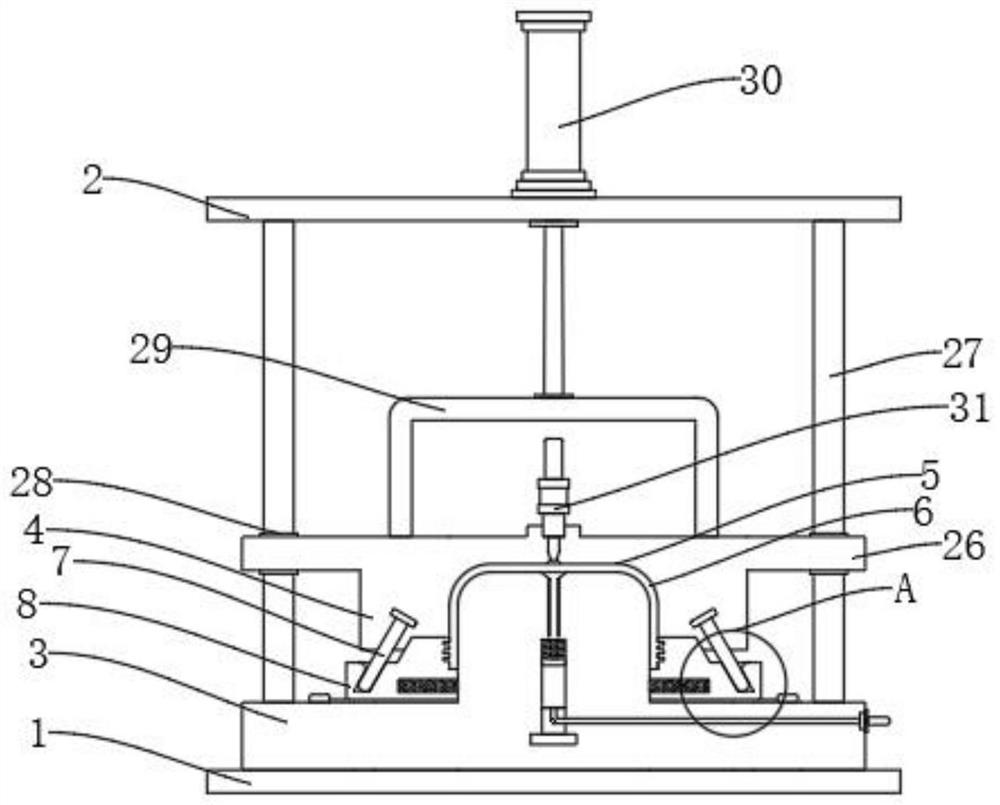

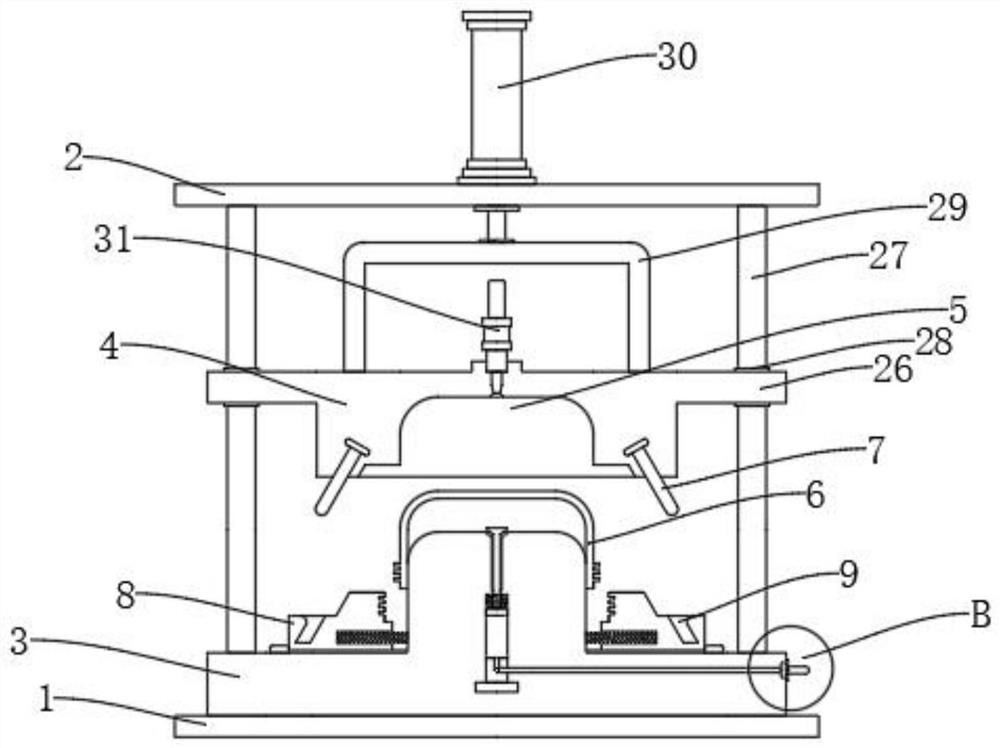

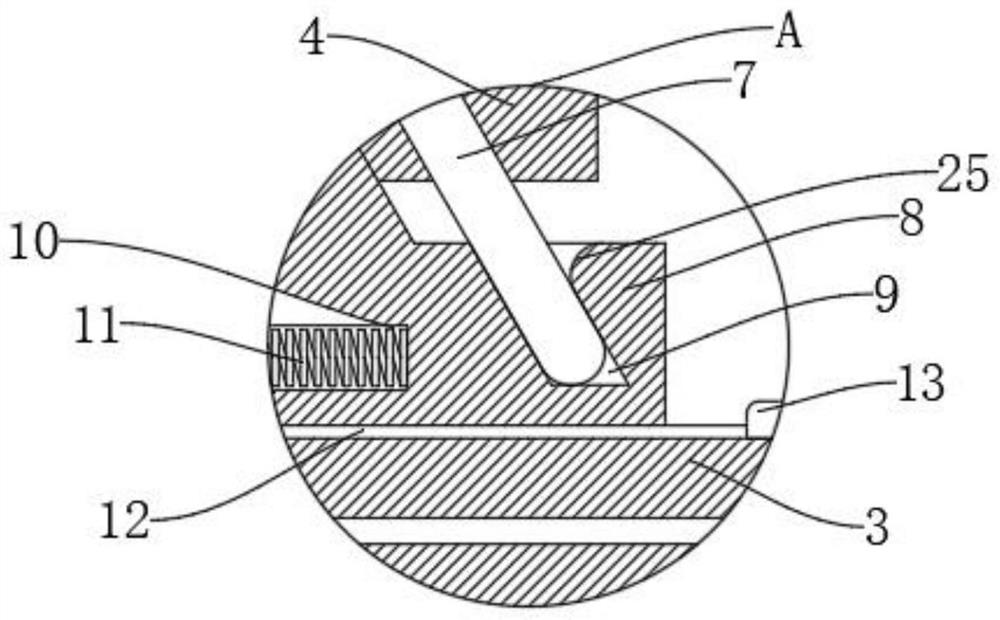

Gypsum block molding device and operation method thereof

PendingCN108908680ALower the altitudeImprove stabilityDischarging arrangementCeramic shaping plantsGypsum blockMaterials science

The invention discloses a gypsum block molding device and an operation method thereof. The gypsum block molding device comprises a hydraulic device, a mold bottom plate, a bottomless mold, ejector rods and a rack; insertion slots and insertion holes are formed in the mold bottom plate; the hydraulic device is fixedly provided with the bottomless mold; a plurality of mold cores and partition platesare arranged in a cavity of the bottomless mold at intervals; when the hydraulic device drives the bottomless mold to make contact with and match with the mold bottom plate, the partition plates areinserted in the insertion slots of the mold bottom plate, the mold cores are inserted in the insertion holes of the mold bottom plate, and the cavity of the bottomless mold can be divided into a plurality of molding cavities with lower openings being closed through the partition plates; an ejector rod fixing frame is fixedly arranged on the rack, and the multiple ejector rods are fixedly arrangedon the ejector rod fixing frame and located over the molding cavities; and when the hydraulic device drives the bottomless mold to move upwards, gypsum blocks are jacked out of the bottomless mold through the ejector rods. The gypsum block molding device has the advantages of high production efficiency, good product quality, high stability and safety and convenient repairing and maintenance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

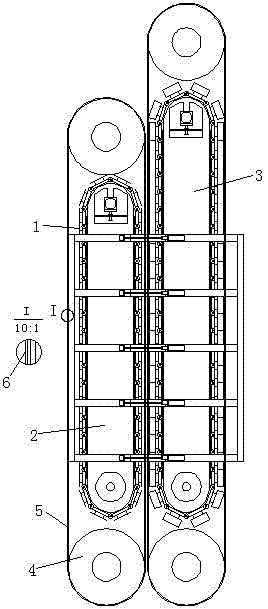

Stripping method and device for foam board continuous molding machine

InactiveCN102806624AEasy to processReduce processing costsFlat articlesMolding machineProcess engineering

The invention relates to the processing field of foam board molding machines, in particular to a stripping method and device for a foam board continuous molding machine. The stripping method for the foam board continuous molding machine is characterized in that the rotating speed of a driving roller is the same as that of the upper and the lower bodies of the foam board continuous molding machine; the driving roller drives a conveyor belt to rotate at a constant speed; the conveyor belt has the same speed with the track shoes of the upper and the lower bodies and is adhered with the track shoes; and a self-stripping layer, of which the interface material is a polytetrafluoro or polyethene coating, is adhered on the conveyor belt to realize an isolation and anti-bonding function and facilitate the solidification and the molding of the boards. The stripping method and device for the foam board continuous molding machine have the advantages that the processing is easy, manual film removing is replaced with the self-stripping of the machine, and the self-stripping layer can be reutilized, so that the processing cost is reduced and the stripping quality is improved.

Owner:胡玉

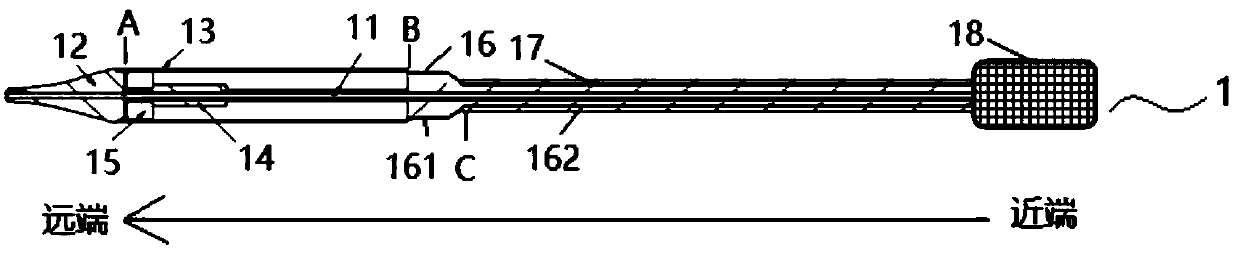

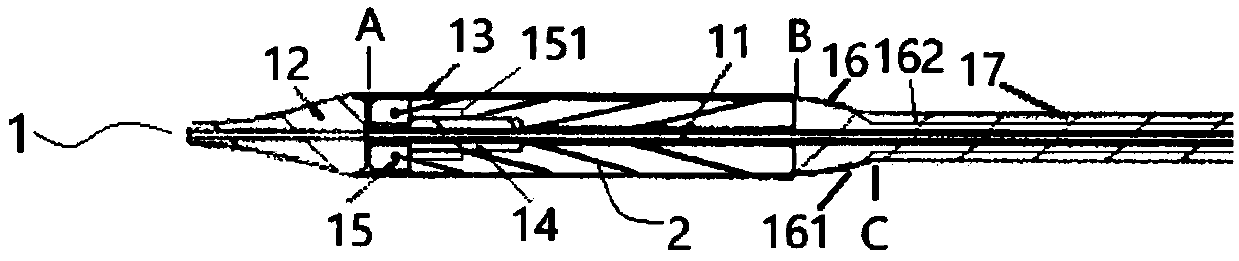

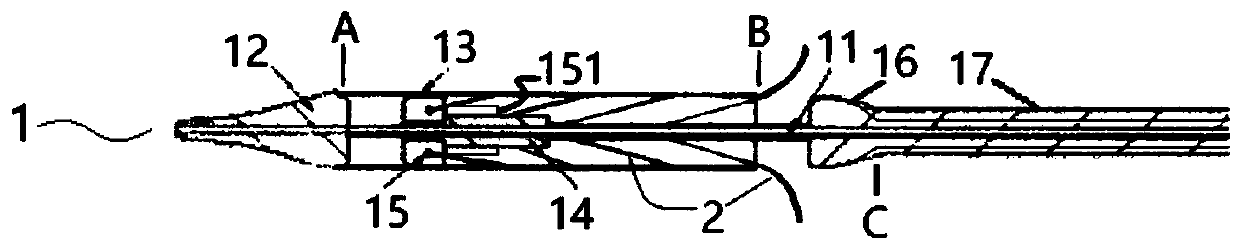

Conveying device

PendingCN110870811AAvoid release instability or even errorsImprove release qualityStentsHeart valvesMechanical engineeringBiomedical engineering

The invention discloses a conveying device. The device is used for loading, conveying and releasing an implant; and the conveying device comprises a handle, an inner core tube, a sheath tube and a guide head, the near end of the inner core tube is connected with an inner core tube movable part in the handle, and the guide head arranged at the far end of the inner core tube is fixedly connected with the far end of the sheath tube, wherein the near end refers to one end close to the handle, and the far end refers to one end far away from the handle. In the device, the far end of the sheath tubeis fixedly connected with the guide head, so that the conveying device can only load the implant through the near end of the sheath tube, when the implant is released, the sheath tube should move to the far end, that is, the sheath tube continues moving forward to the target position of the implant, instead of retreating towards the handle, so that problems such as unstable or even wrong implant release caused by retreating through a three-dimensional curved path of a sheath tube can be effectively avoided, and the release quality of the implant can be improved.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

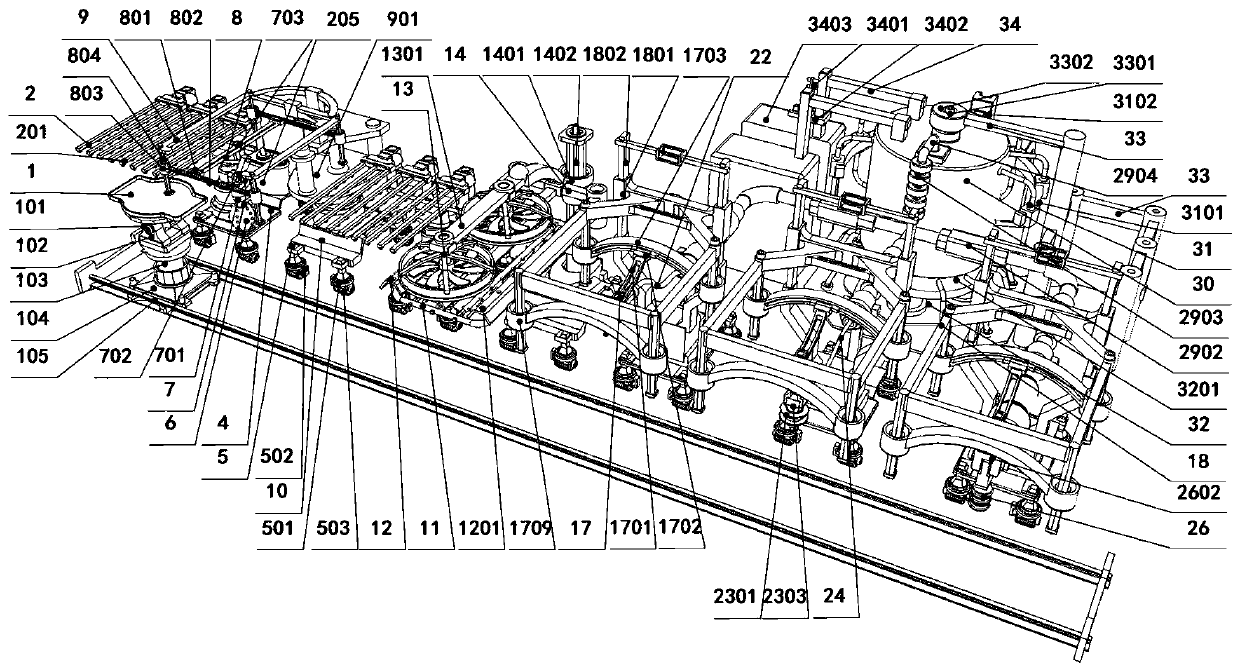

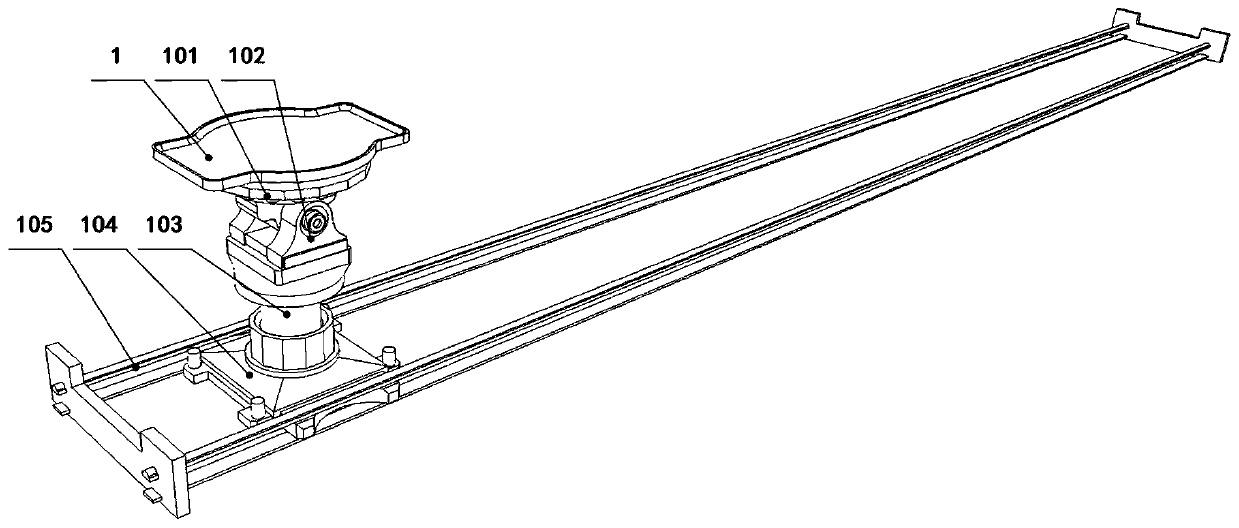

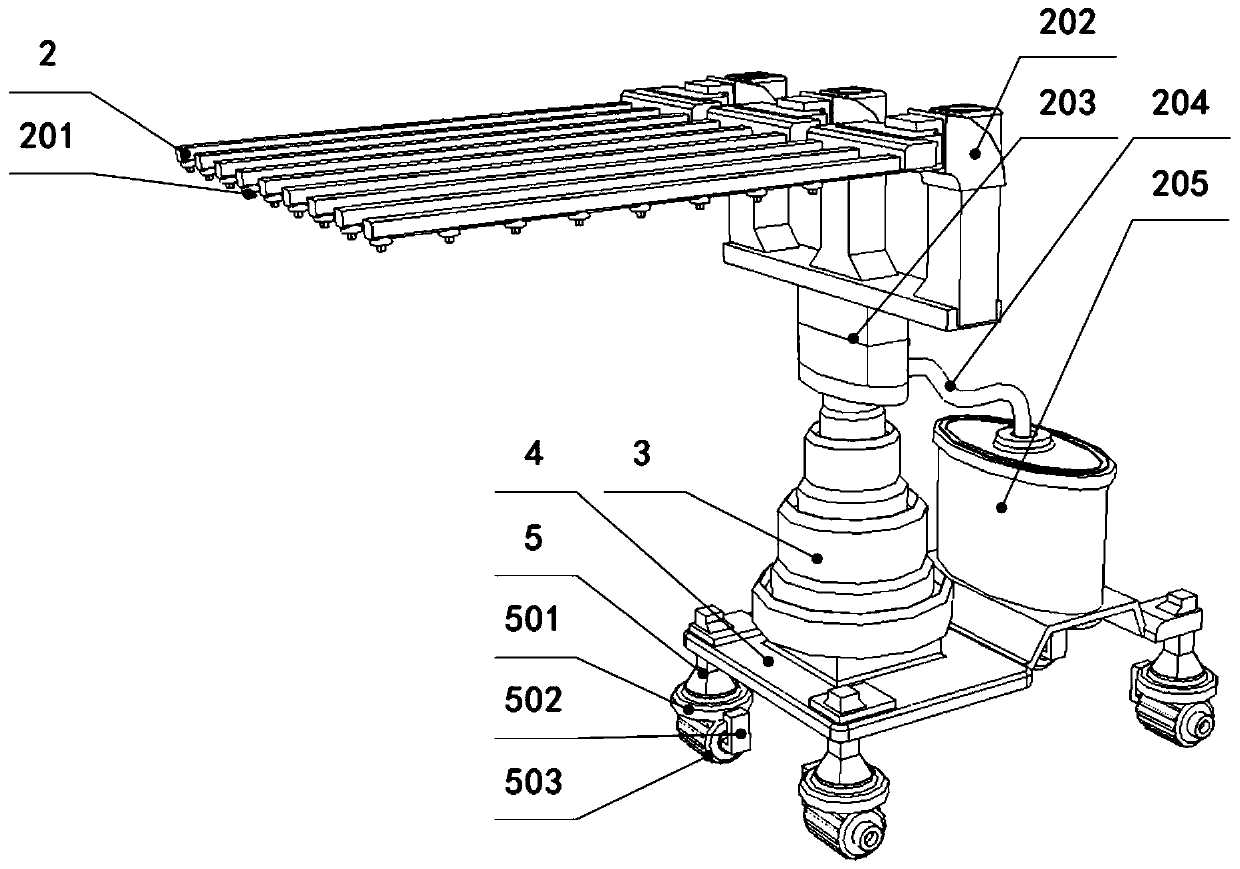

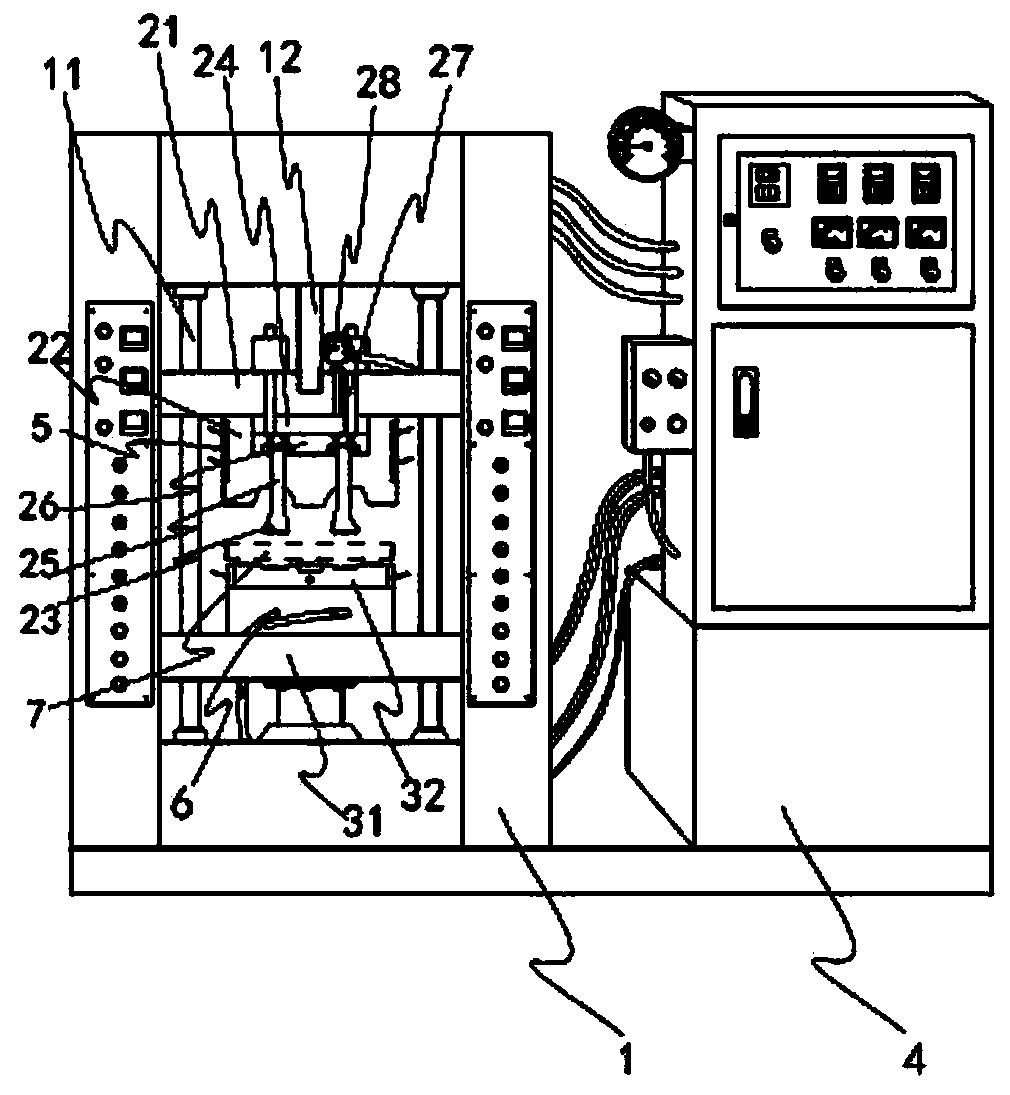

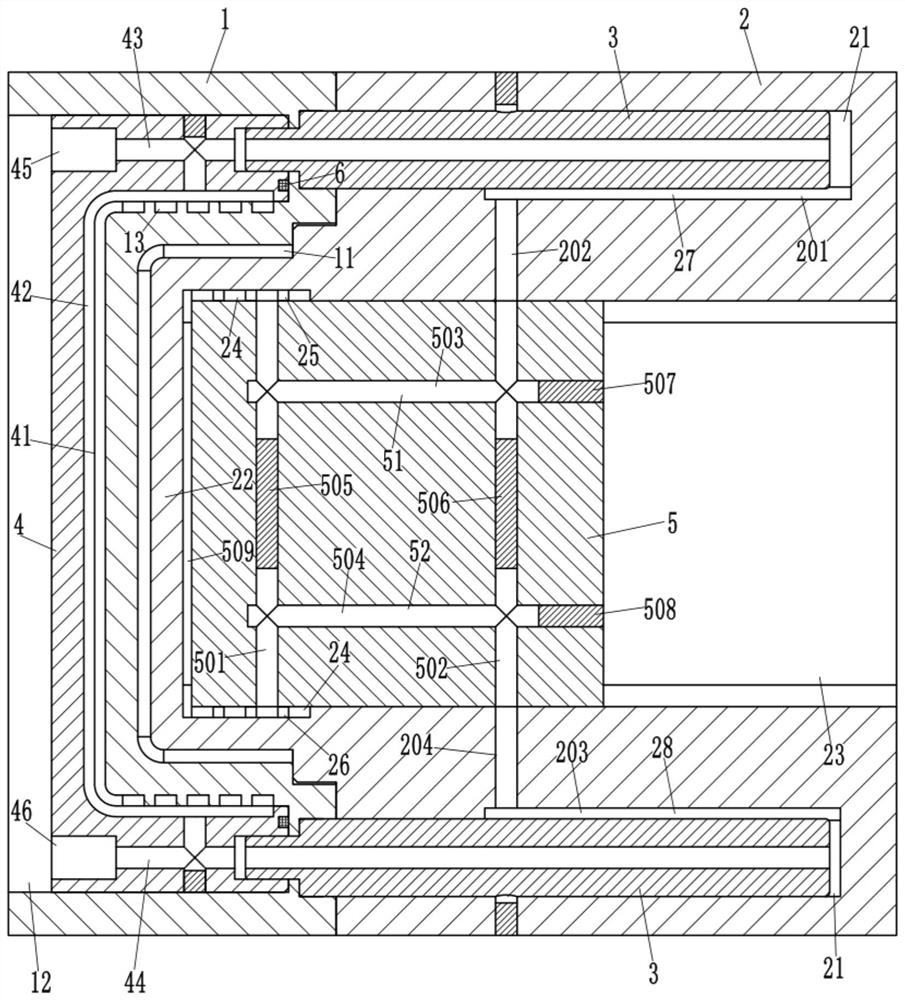

Intelligent spraying device for shield segment mold

ActiveCN111360986AThere will be no transgenderQuality improvementCeramic shaping apparatusCoating systemControl engineering

The invention discloses an intelligent spraying device for a shield segment mold. The intelligent spraying device comprises a moving system, a wiping system, a drying system, a sprinkle coating system, a spraying system, a roll coating system and a feeding system, wherein the wiping system, the drying system, the sprinkle coating system, the spraying system, the roll coating system and the feedingsystem are located on one side of the moving system in sequence. According to the intelligent spraying device for the shield segment mold, water removal and real-time quality inspection are carried out on a mold release agent through the feeding system before the material mixing operation, it is ensured that the supplied mold release agent raw material has low water content, denaturation due to long-term mixing with water of the release agent does not occur, and the mold release agent raw material and water are fully stirred under the constant temperature condition, so that the prepared moldrelease agent is good in quality and guarantees the follow-up coating operation; multi-time coating operation is carried out on the inner wall of the mold by means of multiple coating modes, the positions such as faces, points, wee positions, bent positions and irregular positions can be uniformly coated with the mold release agent, and the influence of the surface condition of the mold on the film forming quality of the mold release agent is weakened to the maximum extent, so that the demolding process of the mold in the follow-up operation process can be smoothly completed.

Owner:济南轨道中铁管片制造有限公司

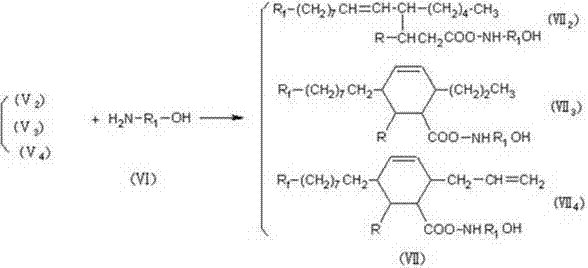

Method of synthesizing a fluorine-containing demoulding additive with agricultural processing side product cardanol

InactiveCN106892938AAdequate sources of raw materialsLow costAdditivesPhosphorus organic compoundsSide productProduct processing

The invention discloses a method of synthesizing a fluorine-containing demoulding additive with agricultural processing side product, cardanol. The method uses a natural and reproducible agricultural processing side product, cardanol, to synthesize a fluorine-containing ester demoulding additive, so that the method has abundant raw material source and low cost. The demoulding additive is added to a demoulding agent and can satisfy market demands of high-end fluorine-containing demoulding additives. The demoulding additive can improve demoulding efficiency and product processing quality, satisfies high-end market demands, and has excellent economic and social benefits.

Owner:修建东

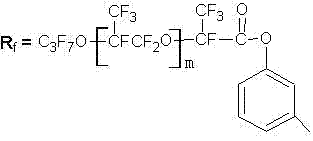

Preparation method of high-performance aluminum alloy blistering mold

InactiveCN105058636AProcess arrangement is reasonableThe preparation process is simpleElectrophoretic depositionLubrication

The invention discloses a preparation method of a high-performance aluminum alloy blistering mold. The preparation method comprises the following steps: (a) selecting and preparing materials; (b) preparing an electrophoretic deposition solution; (c) performing deposition; (d) performing after treatment of the mold. The invention discloses the preparation method of the high-performance aluminum alloy blistering mold; the preparation method is reasonable in procedure arrangement, simple and convenient in preparation process and moderate in cost; a molybdenum disulfide coating prepared on a working surface of the mold has the advantages of stable film forming property, high presentation quality and the like, so that the blistering mold is excellent in self-lubrication property, and the demolding efficiency and the finished product quality of a blister product are effectively improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

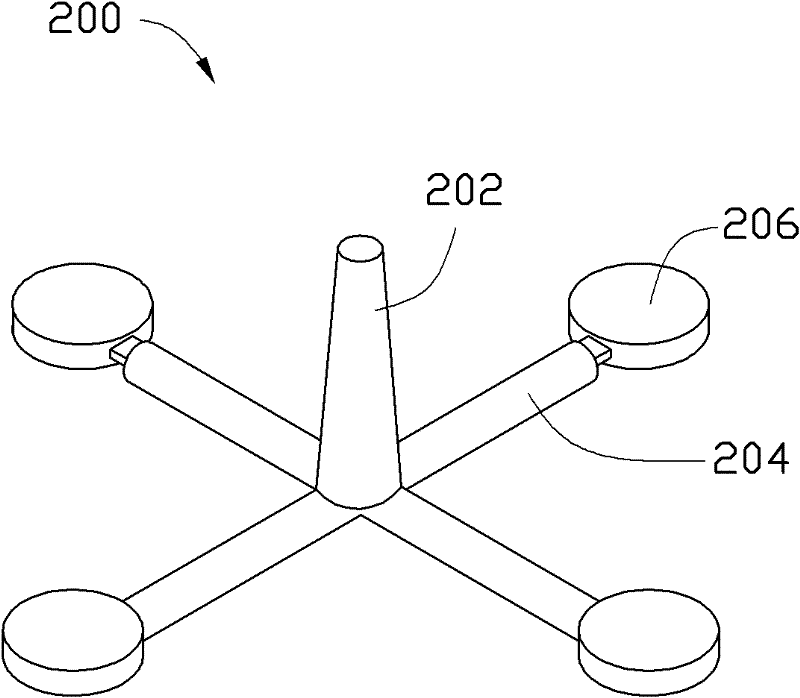

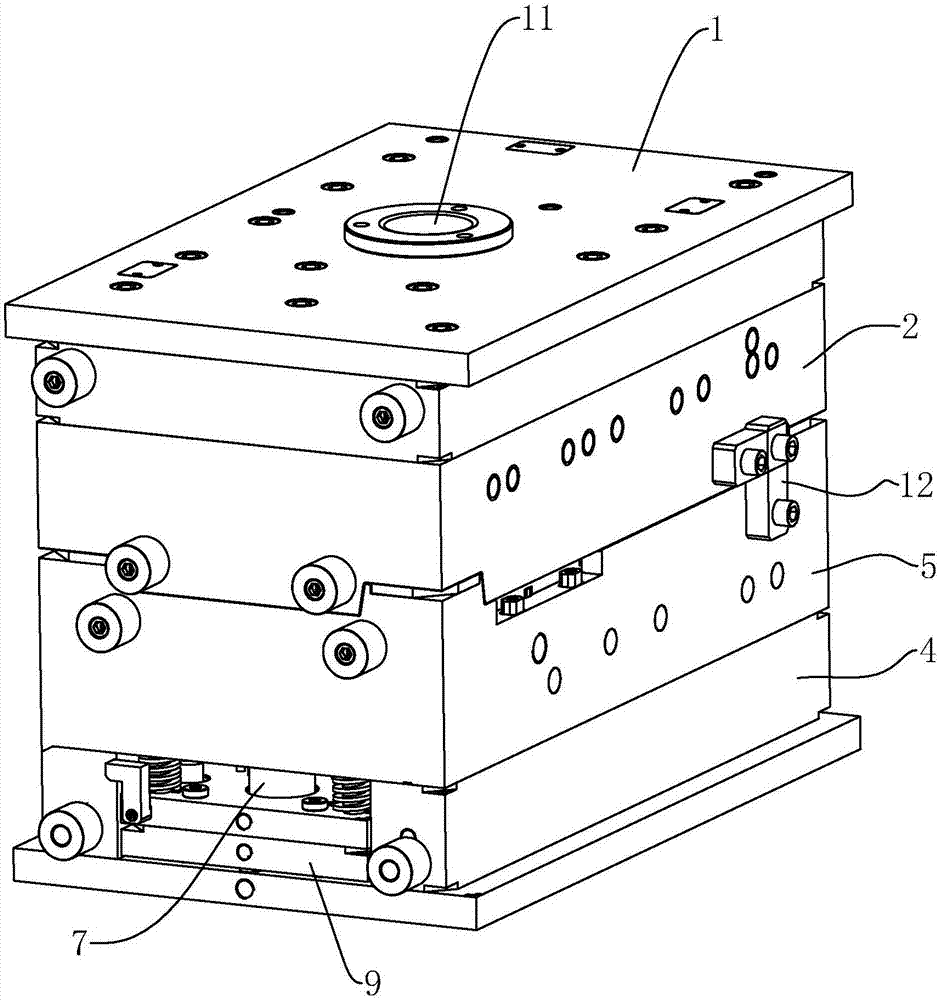

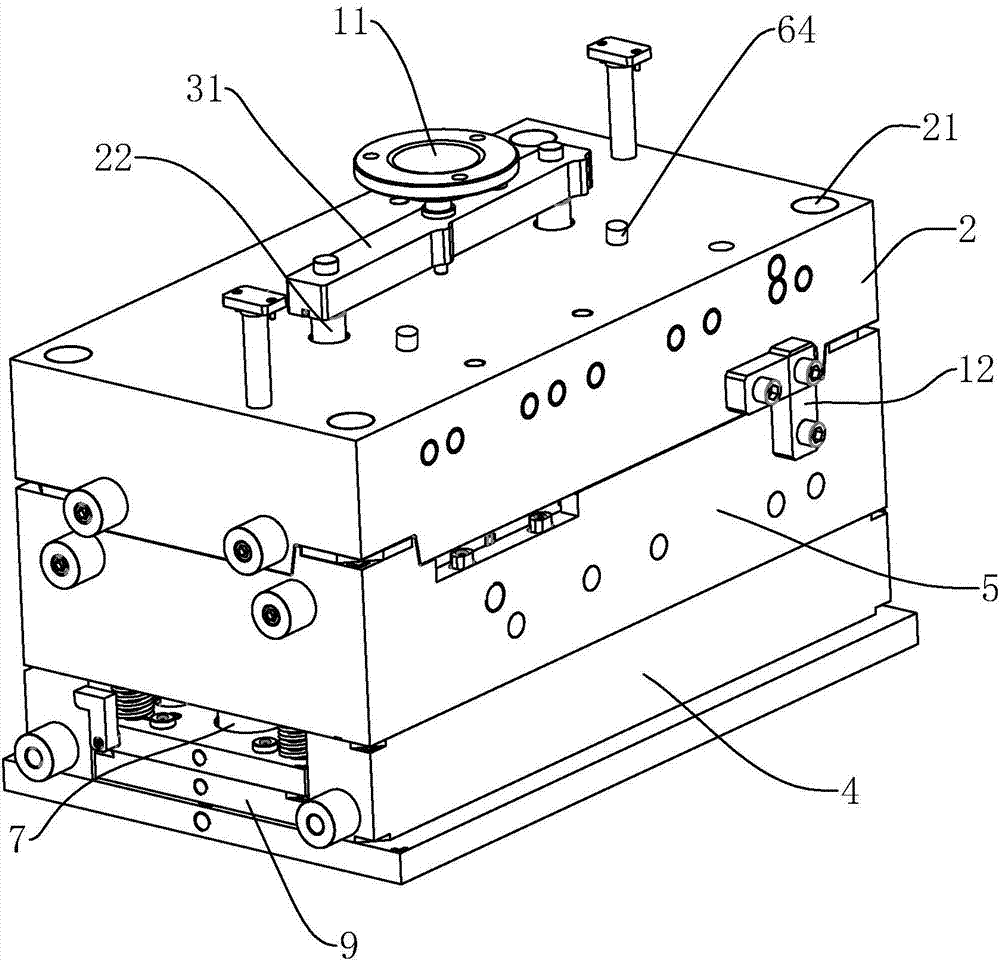

Column re-attachment demolding device

InactiveCN108566739AImprove release qualityIncrease success ratePrinted circuit assemblingEngineeringSupport plane

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Mold device easy to demold

The invention relates to a shoe-making mold, and discloses a mold device easy to demold. The mold device has a simple structure and is quickly demolded, and yield and production efficiency of injection molding is effectively improved, and the mold device is suitable for mass production and use. a telescopic cavity is arranged on an upper die core positioned above an upper mold cavity of the mold device; a brake rod is arranged on a shoe tree and can move up and down and penetrate into the telescopic cavity; a brake plate is fixedly connected to the end of the brake rod in the telescopic cavity; a telescopic base is arranged on the upper mold base, a telescopic rod capable of moving up and down penetrates through the telescopic base, and one end of the telescopic rod penetrates into the telescopic cavity and is connected with the brake plate; a pressurizing device is also arranged on the upper mold base, and a pressurizing end of the pressurizing device communicates with the telescopiccavity; and an exhaust valve is also arranged on the telescopic cavity.

Owner:MAOTAI FUJIAN SOLES CO LTD

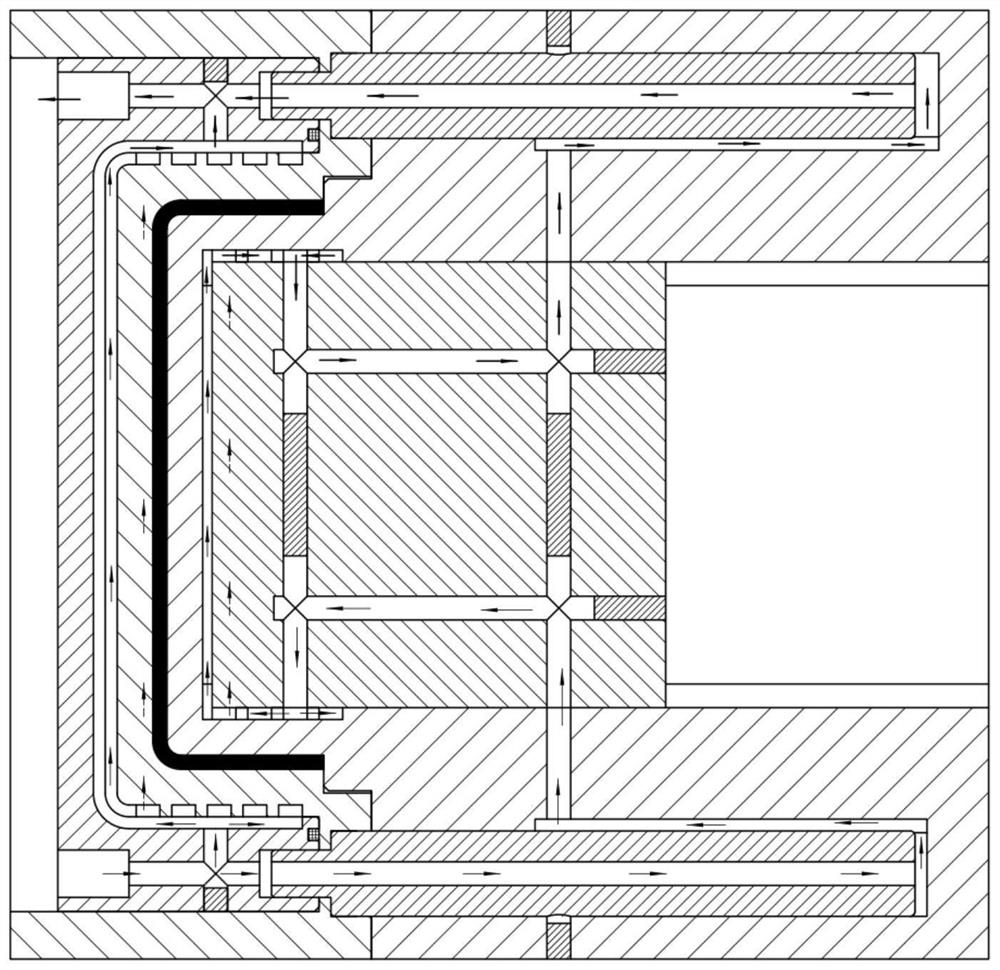

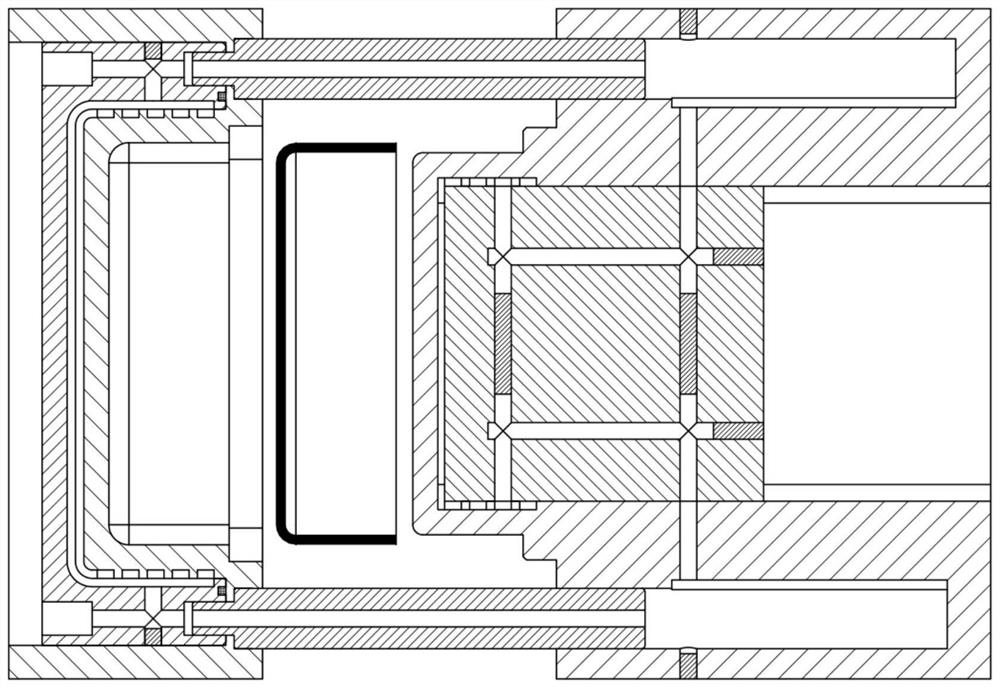

Injection mold cooling system facilitating demolding

The invention discloses an injection mold cooling system facilitating demolding. The injection mold cooling system comprises a female mold and a male mold, and cooling water runners are formed in theinner side of a mold core of the male mold and the outer side of a mold cavity of the female mold; cooling water enters from a water inlet main runner of a cooling water transfer part, and then the cooling water is divided into two paths to respectively flow towards the cooling water runners formed in the inner side of the mold core of the male mold and the outer side of the mold cavity of the female mold and finally enters a water drainage main runner of the cooling water transfer part; and the male mold and the female mold convey cooling water through guide pipes. According to the injectionmold cooling system, by rapidly cooling the mold cavity and the mold core, the time for cooling a plastic product is shortened, the demolding quality of the plastic product can be improved, and meanwhile, the production efficiency of the plastic product is improved.

Owner:何翠珊

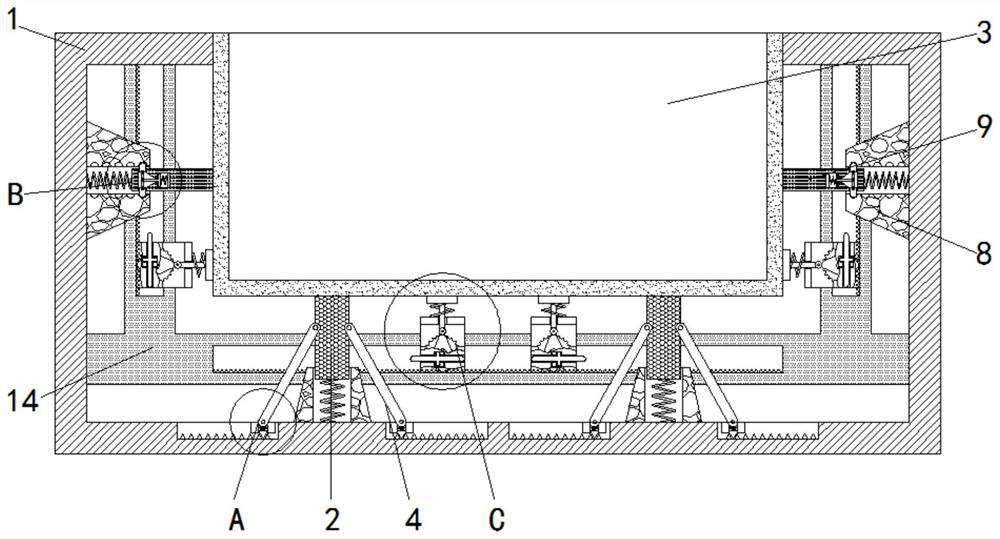

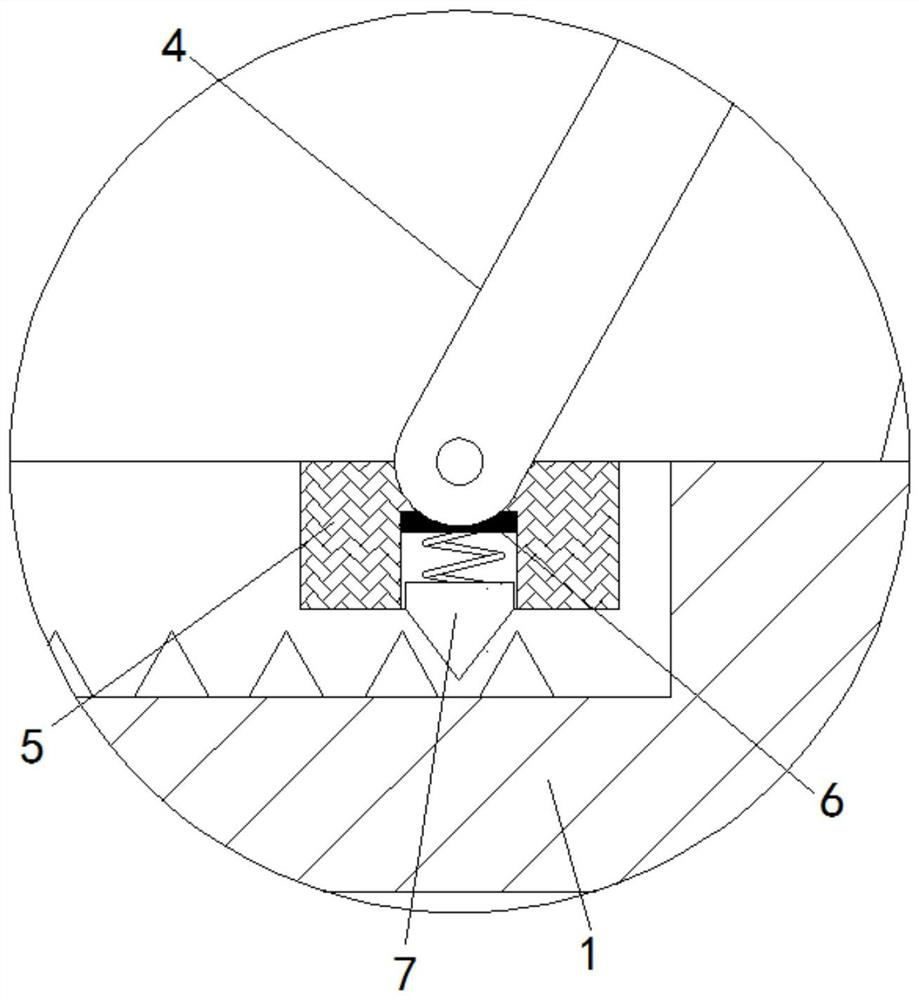

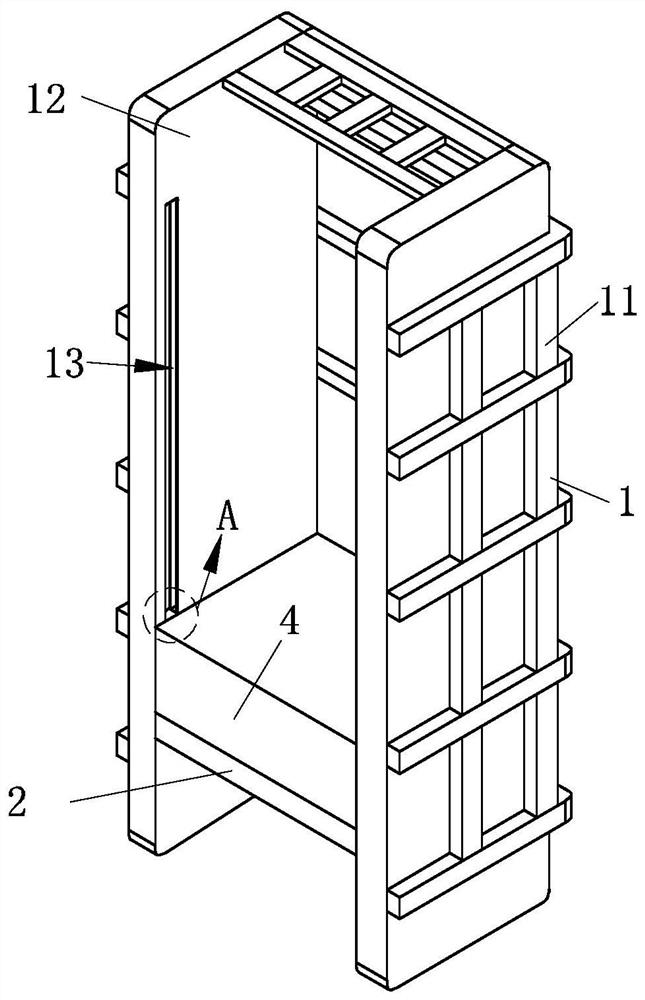

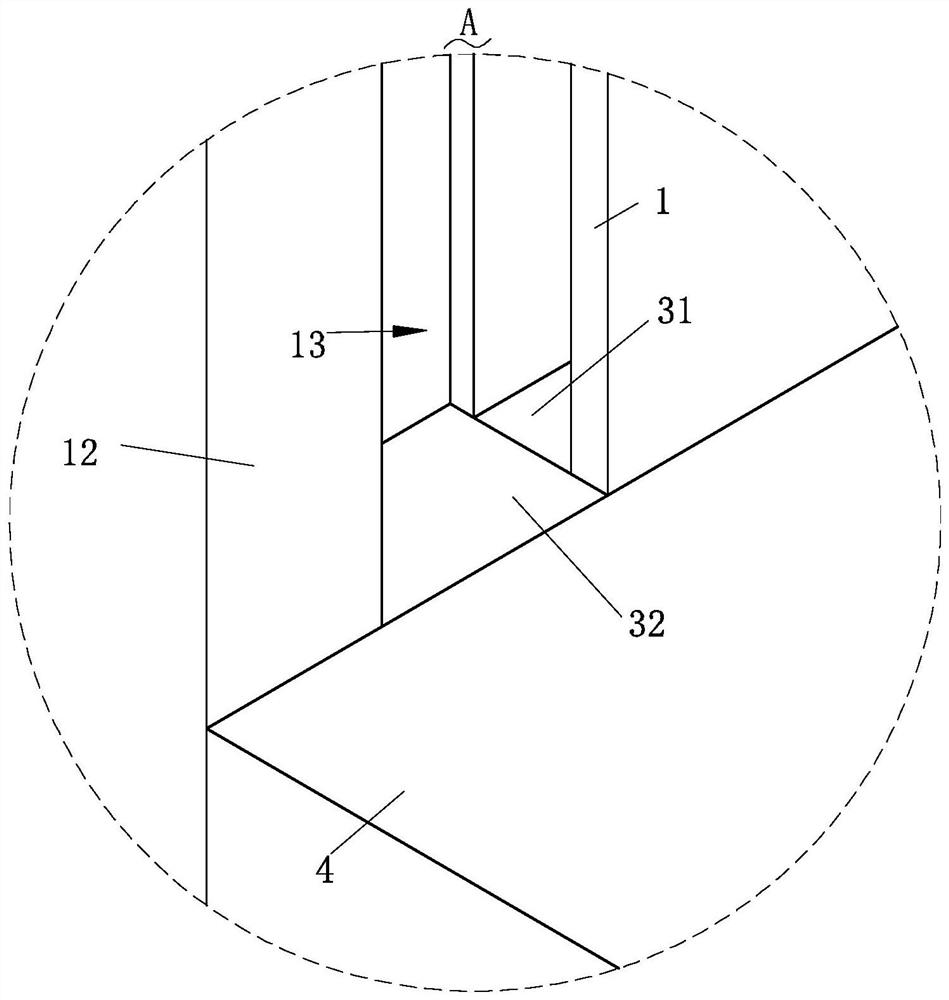

Forming device capable of realizing automatic demolding and used for prefabricated part

InactiveCN112959489AAutomatic demoulding reachesImprove release qualityDischarging arrangementGear wheelCam

The invention relates to the technical field of concrete prefabricated parts, and discloses a forming device capable of realizing automatic demolding and used for a prefabricated part. The forming device comprises a shell, a support rod is glidingly connected to the inner bottom of the shell, a mold is fixedly connected to the top of the support rod, a supporting rod is movably connected to the outer side of the support rod, a sliding box is glidingly connected to the interior of a guide rail, a gear is fixedly connected to the interior of the sliding box, a cam is fixedly connected to the front surface of the gear, an ejector rod is glidingly connected to the interior of the sliding box, a rubber hammer is glidingly connected to the top of the sliding box, and the outer side of the rubber hammer is sleeved with a supporting spring. According to the forming device capable of realizing automatic demolding and used for the prefabricated part, the gear rotates to drive the sliding box to move under the action of a tooth groove, the sliding box drives the rubber hammer to move, meanwhile, the gear rotates to drive the cam to rotate, the cam drives the rubber hammer to slide, and then through cooperative use of the rubber hammer and the supporting spring, the effects of automatic demolding and high demolding quality are achieved.

Owner:祝锡明

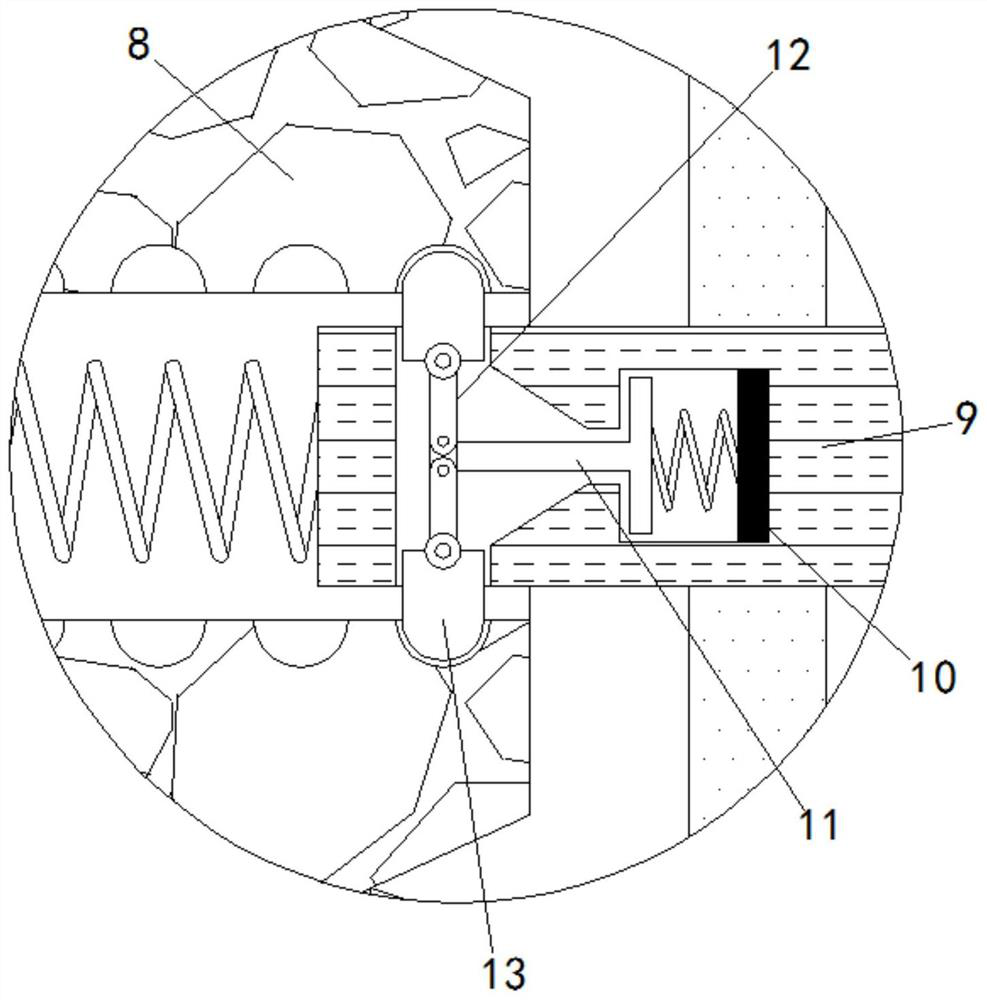

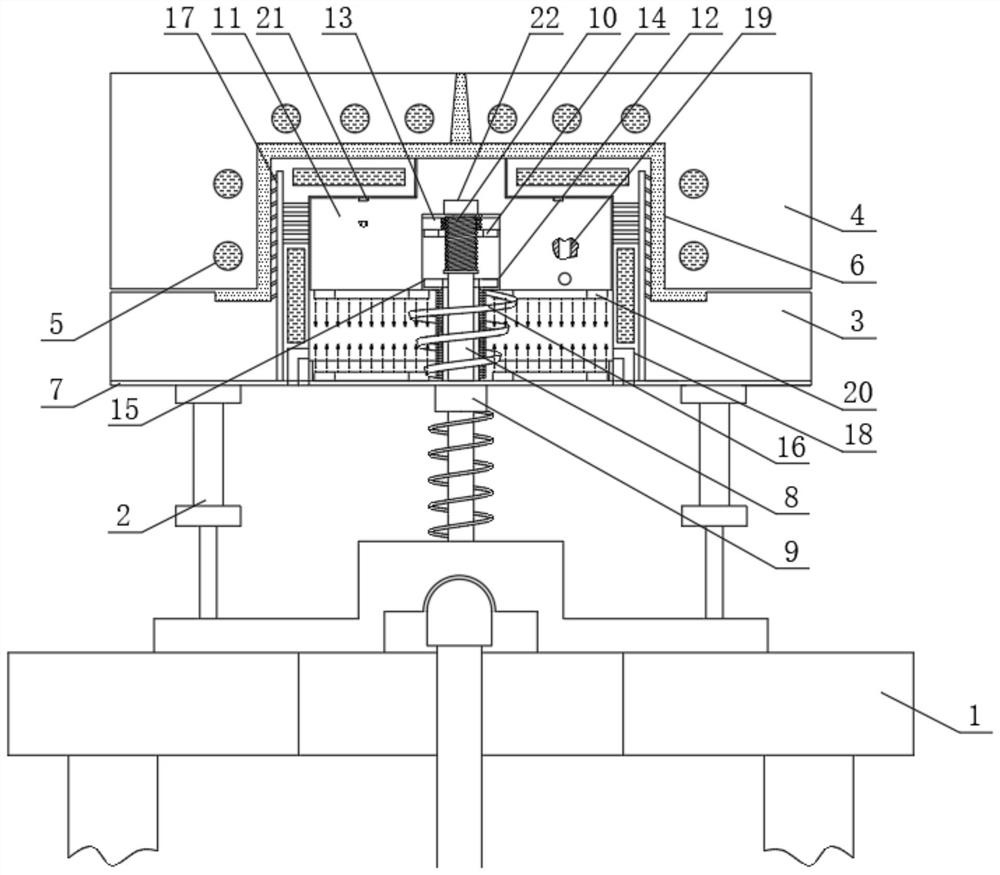

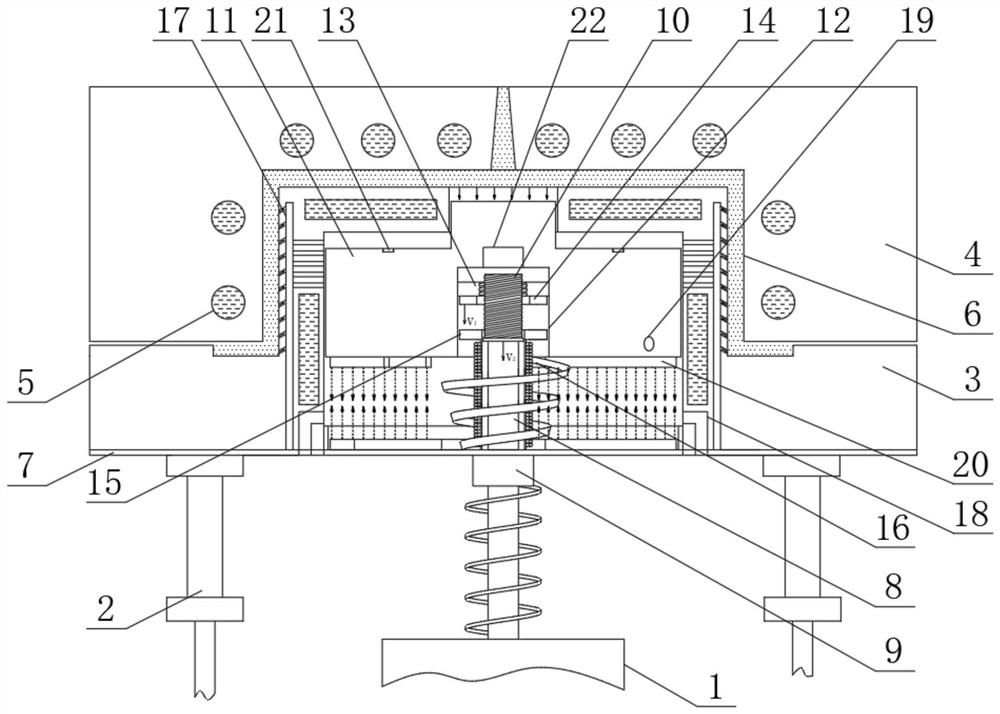

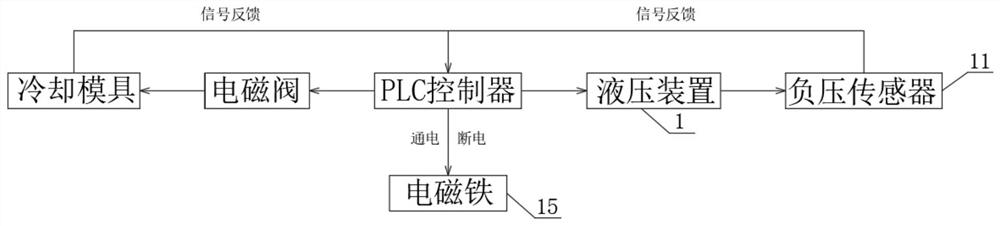

an injection mold

Owner:苏州宇鑫精密模具有限公司

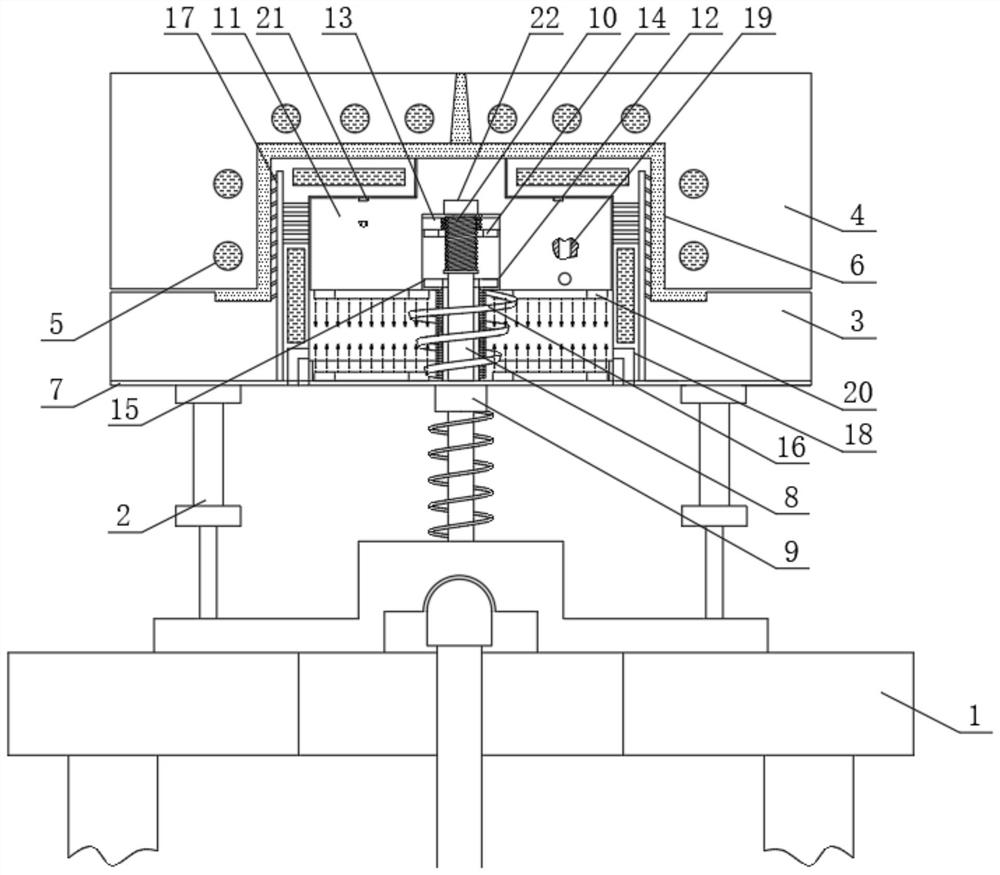

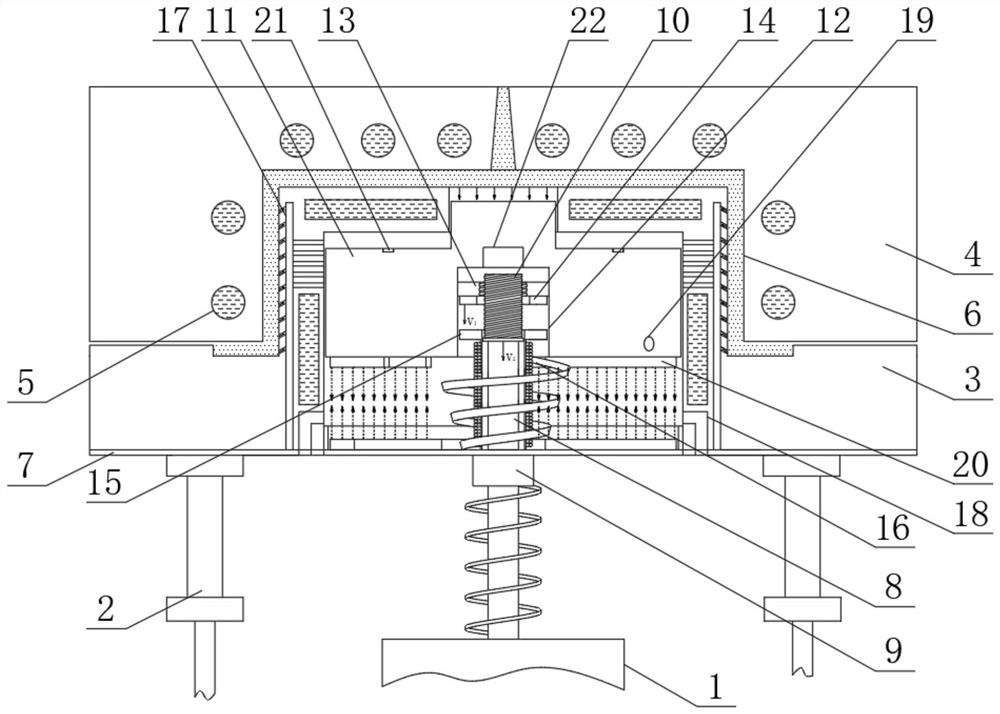

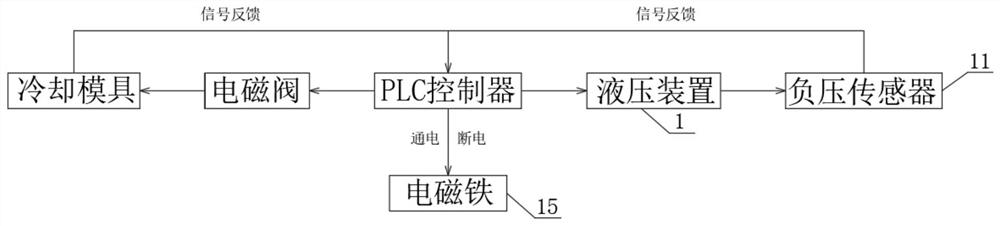

Injection mold

The invention relates to the technical field of injection molds, and discloses an injection mold. The injection mold comprises a hydraulic device, a hydraulic rod movable mold and a fixed mold, wherein the hydraulic device is in transmission connection with the movable mold through a hydraulic rod, a mold cavity is formed between the movable mold and the fixed mold, a cooling water channel is formed in the mold cavity, a pouring opening is formed in the middle of the fixed mold, the pouring opening communicates with the mold cavity and communicates with an injection molding machine, the middleof the movable mold is in a groove shape, the groove communicates with the mold cavity, a sealing piece is driven to move downwards under the action of a hollow electromagnet, and therefore gradually-changed negative pressure is formed between the sealing piece and the movable mold firstly. The gradually-changed negative pressure acts on the injection molding piece, slow separation between the outer wall of the injection molding piece and the inner wall of the fixed mold can be guaranteed, bonding resistance between the injection molding piece and the fixed mold disappears, separation from the fixed mold is achieved while the movable mold moves downwards, in the demolding process, the surface of the injection molding piece is not bonded with the fixed mold during demolding, resistance isrelatively small, and the surface quality of the injection molding piece during demolding is improved.

Owner:苏州宇鑫精密模具有限公司

Wear-resistant lining material and preparation method

The invention discloses a wear-resistant lining material and a preparation method. The preparation method includes following process steps: mixing raw material powder with an auxiliary; forming by pressing; sintering; subsequently processing. The wear-resistant lining material is mainly composed of silica, manganese dioxide, molybdenum disulfide, cerium oxide, cobalt oxide, silicon carbide, ZNS-730, chromium, tin, copper, phosphorus, graphite powder, zirconium, nickel, iron and unavoidable impurities. By improving ingredient proportioning and optimizing powder metallurgy process parameters, rare earth elements and strengthening elements are utilized to generate solution strengthening and dispersion strengthening effect. Compared with existing products, the lining material produced by the method is high in wear resistance and strength, low in friction coefficient and widely used for various wheel shafts, connecting rods and air pumps in industrial production.

Owner:WUHU SANDAO MATERIAL TECH CO LTD

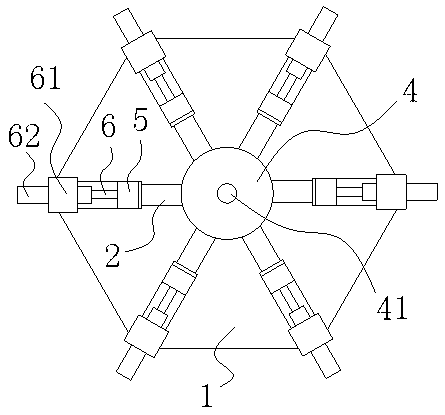

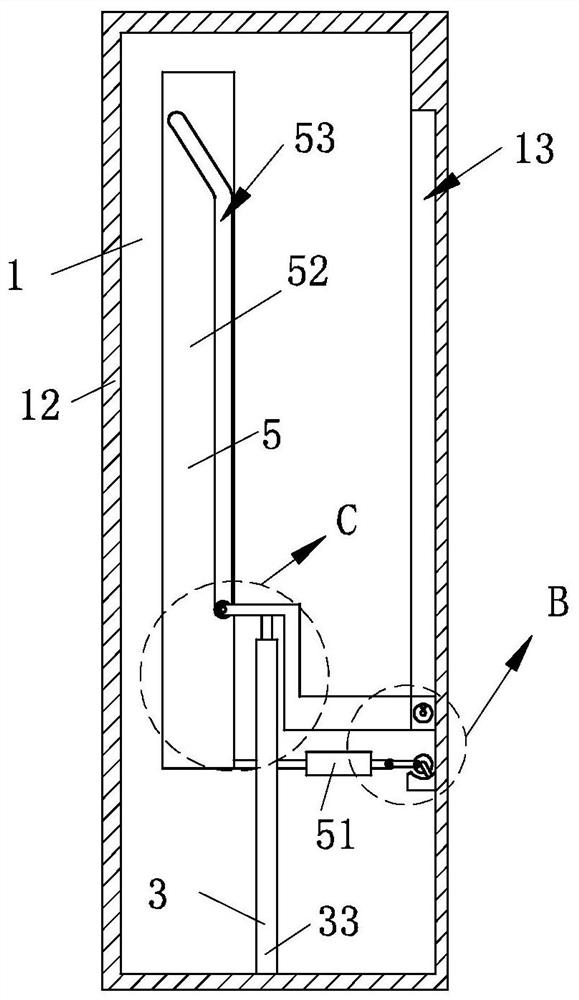

Industrial belt stripping machine adopting jack

PendingCN107775851AImprove demoulding efficiencyImprove release qualityBeltsStructural engineeringLeather belt

The invention provides an industrial belt stripping machine adopting a jack, which can be suitable for stripping of belt coils with various diameter specifications better and improving the stripping efficiency and the stripping quality. The industrial belt stripping machine comprises a base, wherein a plurality of rails are arranged on the base along the center in an outward radial shape; the jackis arranged at the center of the base; a supporting plate is arranged on the top surface of the jack; movable rail seats, which face the center of the base, are arranged on the rails; a face, which faces the center of the base, of each movable rail seat is a compacted face; each compacted face is provided with a soft base plate; and the movable rail seats are driven through push rods.

Owner:茂名市腾龙工业皮带有限公司

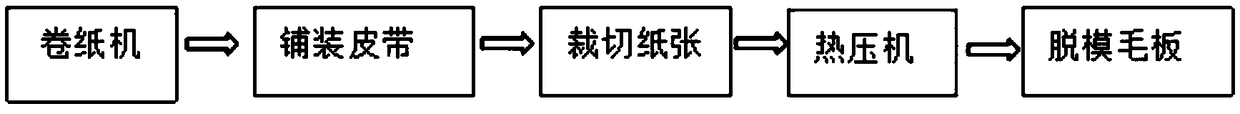

Technology for die releasing of MDI artificial board through special paper

InactiveCN109333746AEasy to demouldImprove demoulding efficiencySpecial paperReinforcing agents additionEngineeringHeat press

The invention provides a technology for die releasing of an MDI artificial board through special paper. The technology is characterized in that before a hot-pressing procedure is conducted, the special paper is laid between a hot-pressed board and an MDI artificial board blank, then the MDI artificial board blank is conveyed into a hot press, under the conditions that the hot-pressing temperatureis 150-220 DEG and the pressure is 2400-3800 kN / m<2>, after curing and releasing are conducted through the hot press, die releasing is conducted, and the special paper is hot-pressed and cured into arough board together with the MDI artificial board blank. The problem of die sticking of the MDI glue artificial board is solved.

Owner:上海世崛资产管理有限公司

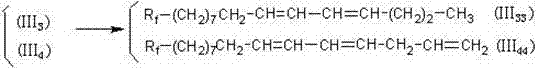

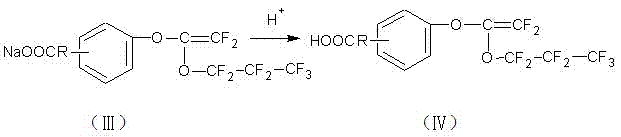

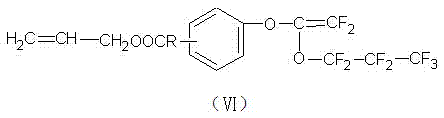

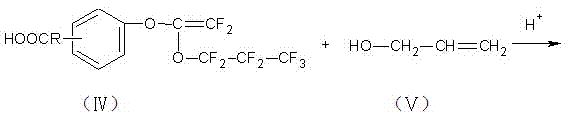

Preparation method of fluorine-containing hydroxyphenyl organic acid alkenyl ester demoulding intermediate

InactiveCN106892816ATo satisfy the market's needsImprove demoulding efficiencyPreparation from carboxylic acid saltsOrganic compound preparationSocial benefitsOrganic acid

The invention discloses a method for preparing a release intermediate of fluorine-containing hydroxyphenyl organic acid alkenyl ester, which is characterized in that: hydroxyphenyl organic acid and decarboxylated hexafluoropropylene oxide dimer undergo nucleophilic substitution reaction, The obtained sodium hydroxyphenyl organic acid substituted by hexafluoropropylene oxide dimer is acidified with acid solution to obtain the hydroxyphenyl organic acid substituted by decarboxylated hexafluoropropylene oxide dimer. And under the polymerization inhibitor, the hydroxyphenyl organic acid substituted by the decarboxylated hexafluoropropylene oxide dimer is finally esterified with propenyl alcohol to obtain the fluorine-containing hydroxyphenyl organic acid alkenyl ester release intermediate; the Fluorine-based release intermediates can be further reacted with acrylic compounds to synthesize high-efficiency fluorine-containing release agents, which can improve release efficiency and product processing quality, meet the high-end needs of the market, and have good economic and social benefits.

Owner:修建东

A kind of easy demoulding aluminum alloy formwork and preparation method thereof

ActiveCN109652835BImprove demoulding efficiencyExtended service lifeAnodisationDextran coatingsPolyvinyl alcoholStearic acid

The invention relates to the technical field of aluminum alloy templates, in particular to an easily-demoulded aluminum alloy template and a preparing method thereof. The aluminum alloy template comprises an aluminum alloy base body and a demoulding layer attached to the surface of the aluminum alloy base body. Raw materials for preparing the demoulding layer include, by weight, 1-5 parts of polyvinyl alcohol, 4-6 parts of stearic acid, 3-5 parts of octadecanamide, 4-8 parts of konjac glucomannan, 15-20 parts of konjaku flour, 15-20 parts of sodium alga acid, 1-3 parts of sodium borate, 5-7 parts of modified shell powder, 5-10 parts of modified silicon dioxide, 2-4 parts of aluminum sulfate, 2-6 parts of sodium methyl silicate, 1-3 parts of sodium dodecyl sulfate and 0.3-0.7 part of organic silicon defoamer. The demoulding layer is directly formed on the surface of the aluminum alloy base body, demoulding is easier, the cyclic usage frequency is larger, the concrete demoulding qualityis improved to a certain degree, and the demoulding efficiency of the aluminum alloy template is improved.

Owner:重庆新久融科技有限公司

A kind of aluminum template release agent of high turnover times ultraviolet light curing and preparation method thereof

ActiveCN109401560BReduce pollutionNo pollution in the processEpoxy resin coatingsUltraviolet lightsMaterials science

The invention provides a high-turnover UV-cured aluminum template release agent, which comprises the following components calculated in parts by weight: 6-10 parts of modified acrylic epoxy resin, 1-3 parts of UV monomer diluent, and 0.1-0.6 parts of force accelerator, 0.1-0.6 parts of leveling agent, 0.1-0.4 parts of surface slippery agent, 0.3-0.9 parts of ultraviolet photoinitiator; modified acrylic epoxy resin is made of acrylic acid, hydroxyethyl acrylate, methane It is prepared by modifying epoxy resin with one or more of phthalic acid, phthalic anhydride, trimellitic anhydride, ethylene glycol diglycidyl ether, and epichlorohydrin. The present invention also provides a preparation method of the above-mentioned release agent. The release agent of the present invention is coated on the aluminum alloy formwork, and is irradiated with ultraviolet light at room temperature to make it solidify into a film. It is used in the concrete pouring process. The demoulding quality of the concrete is good, the surface is smooth and pollution-free, and there is no concrete on the surface of the formwork. Residue, the template can be used up to 100 times after one application of the release agent, prolonging the service life of the template.

Owner:HUNAN HUITIAN HIGH MOLECULAR TECH CO LTD

A pouring mold with self-cooling function

ActiveCN112829149BImprove inspection and maintenance efficiencyQuality improvementMechanical engineeringMold removal

The invention relates to the technical field of pouring molds with self-cooling function, in particular to a pouring mold with self-cooling function, including a supporting structure, a first pouring structure, a driving structure, a second pouring structure, and a transmission structure , the first demoulding structure and the second demoulding structure; it is convenient to drive the second casting structure to rotate 90 degrees through the driving structure while lifting, so as to make the second casting structure face the operator, thereby greatly improving Improve the efficiency and quality of the inspection and maintenance of the second casting structure, and then facilitate the drive structure to drive the transmission structure, so that the transmission structure drives the first casting structure to rotate, thereby greatly improving the efficiency and quality of the inspection and maintenance of the first casting structure Quality: it is convenient to use the drive structure to drive the second pouring structure to rotate, so that the first demoulding structure is in contact with the supporting structure, so that the first demoulding structure can quickly demould the workpiece inside the second pouring structure.

Owner:宁波永朝模具有限公司

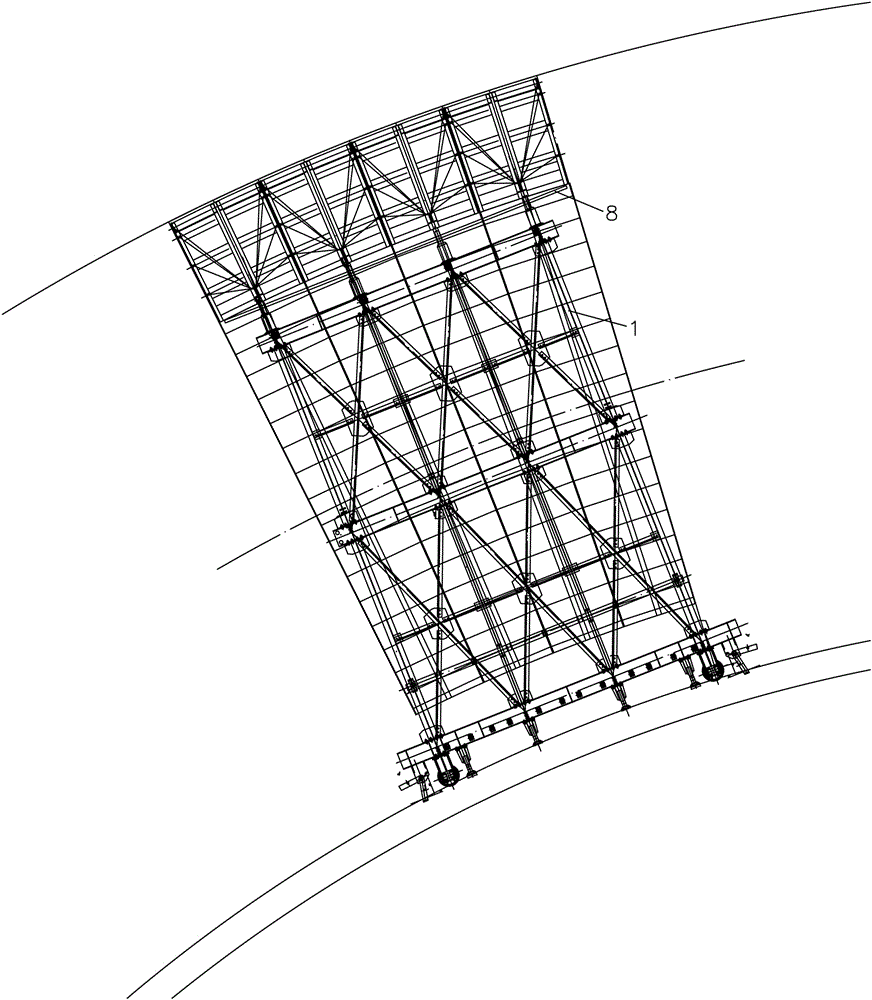

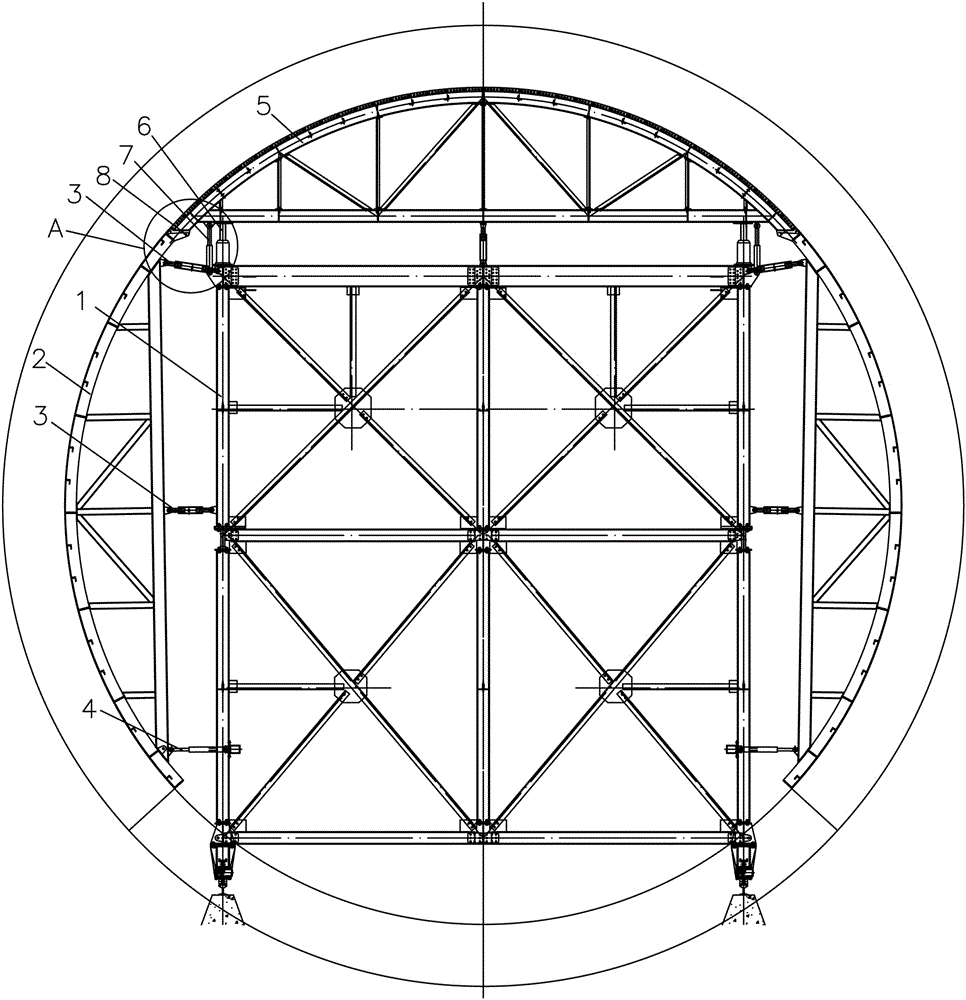

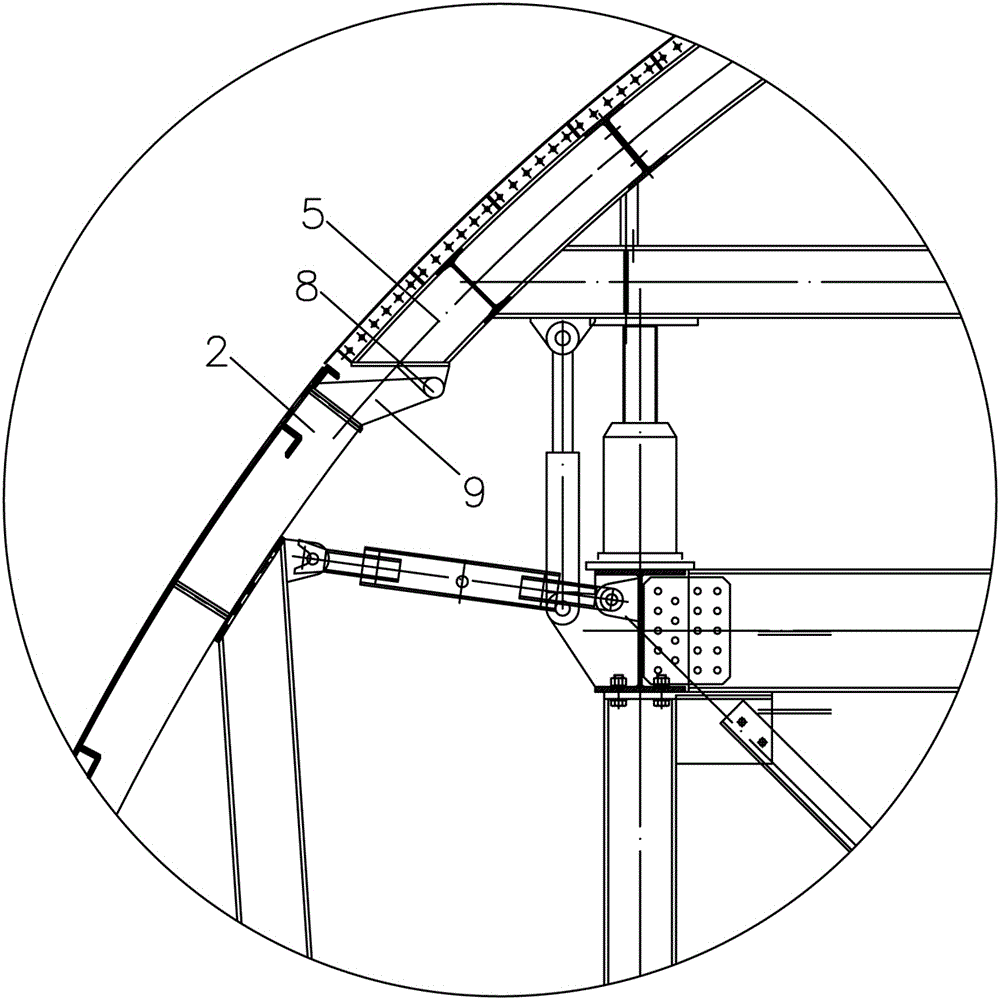

Anti-interference device and method for demoulding and anti-interference of steel mold trolley with three-dimensional space curved surface

ActiveCN104373137BAchieve demouldingNo deformationUnderground chambersTunnel liningThree-dimensional spaceEngineering

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

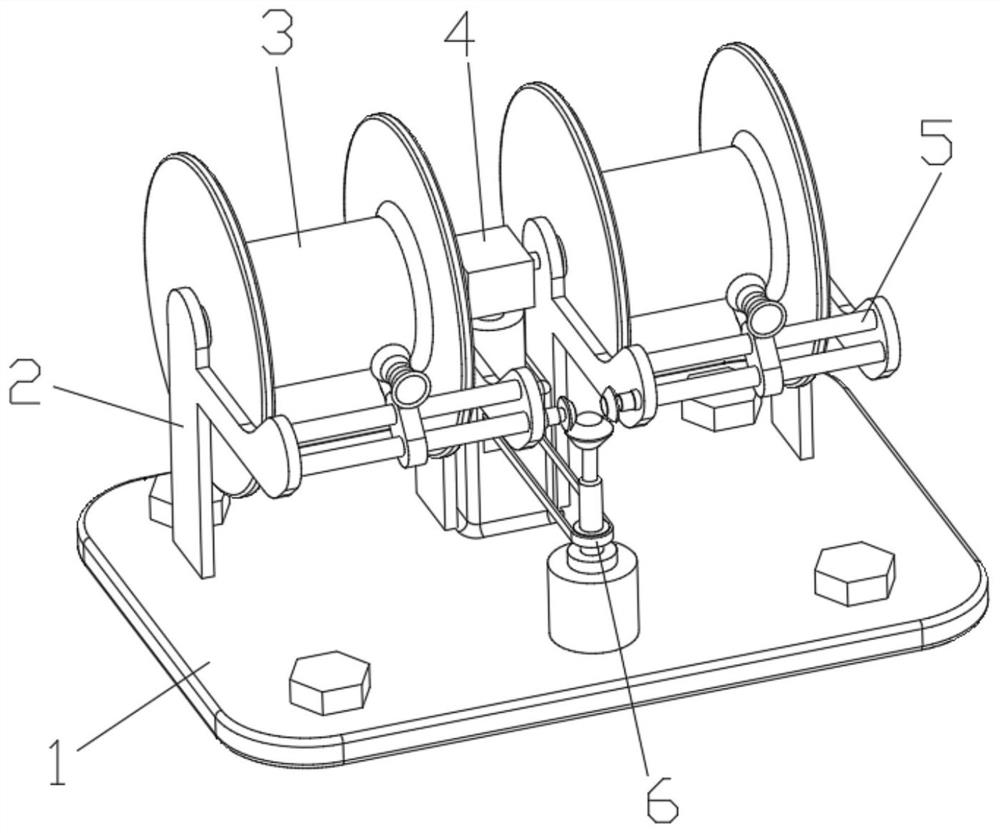

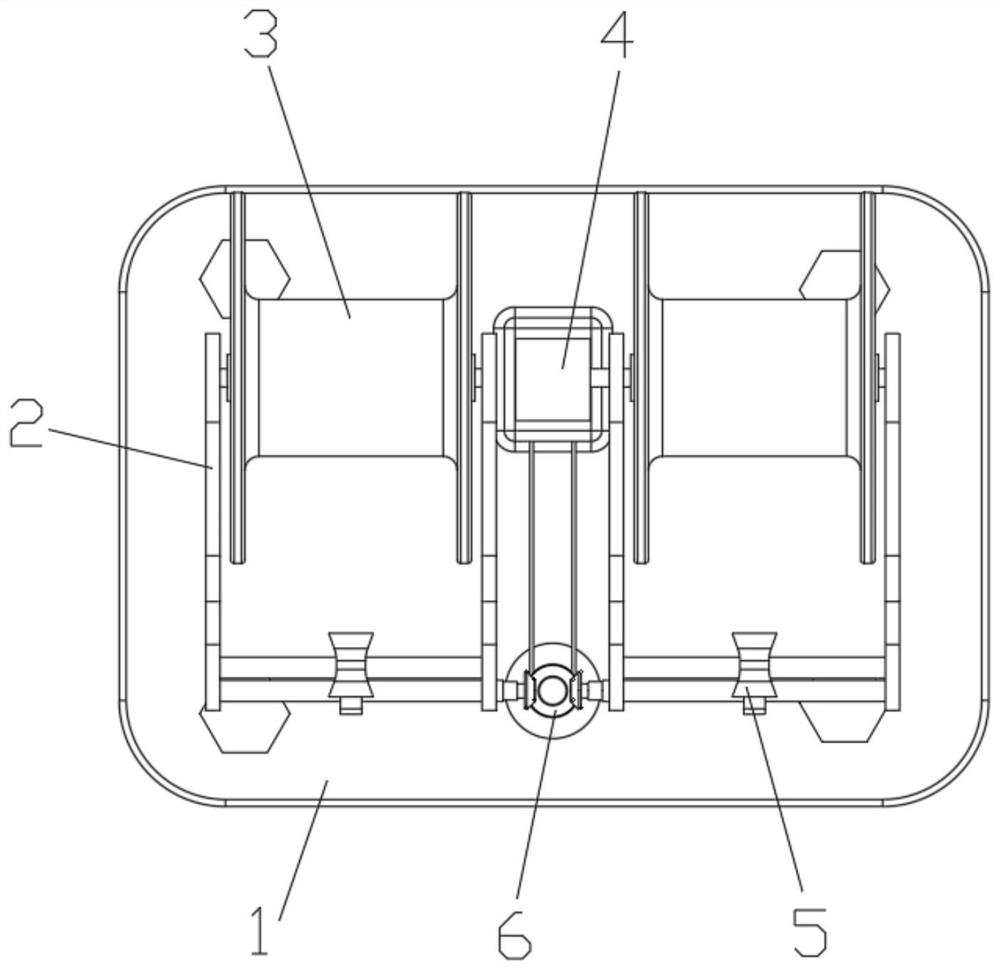

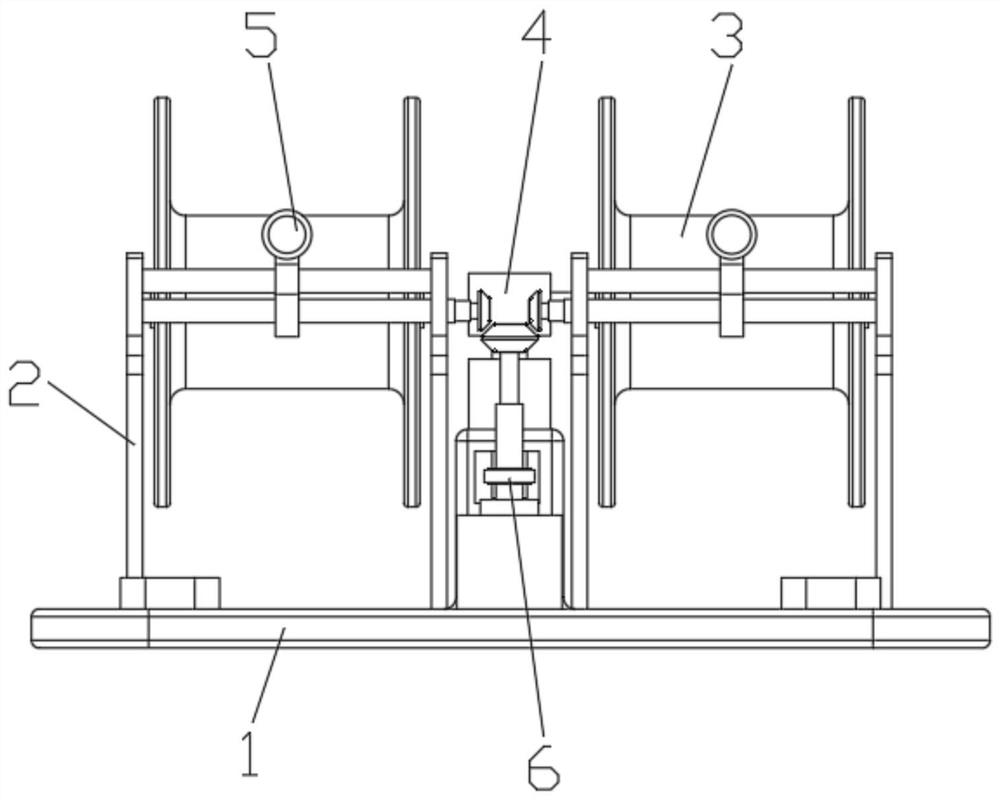

A multifunctional cable retracting device and its control method

The present invention provides a multifunctional cable retracting device and its control method, comprising: a base, multiple mounting frames, two winding mechanisms and a first power mechanism, and multiple mounting frames are fixed on the top surface of the base , the winding mechanism is rotatably arranged between two adjacent installation frames. In the multi-functional cable retracting device of the present invention, the two winding drums rotate in opposite directions at the same time, which facilitates the replacement of worn-out and aging cables in the project with new ones, instead of the traditional need to perform two consecutive operations successively, saving energy. Time and convenient operation, reduce labor intensity; improve the flexibility of use, adapt to a variety of construction scenarios; avoid two cables intertwined with each other, ensure smooth operation, improve the quality of new cables, and extend the service life of new cables ; Only one double-axis motor is used, saving production cost and working electric energy.

Owner:广东和星建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com