Demolding method in nanoimprint technology process

A nano-imprinting and technical technology, applied in the field of micro-nano processing, can solve the problems of tearing and demolding force, deformation of nano-imprinting structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The present invention takes ultrasonic-assisted demoulding in the process of nano hot embossing technology as a specific embodiment.

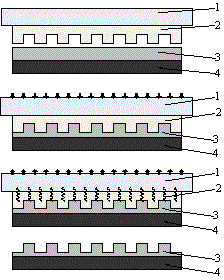

[0016] see figure 1 As shown, an ultrasonic-assisted demoulding method in the process of nano-hot embossing technology, firstly, the nano-imprint polymer is coated on the substrate, heated to melt and soften, and the embossed adhesive layer 3 is formed; then the template 2 Press into the embossed adhesive layer 3; after the embossed adhesive layer 3 is cured and shaped, use the ultrasonic emission device 1 on the upper part of the template 2 to emit ultrasonic waves to the template 2 to assist the separation of the template 2 and the formed embossed adhesive layer 3, and remove the template 2. Complete the demoulding process.

[0017] The ultrasonic waves emitted by the ultrasonic emitting device 1 on the upper part of the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com