Conveying device

A delivery device and proximal technology, applied in the field of medical devices, can solve problems such as inability to adjust, position deviation, etc., and achieve the effect of precise release and improved release quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

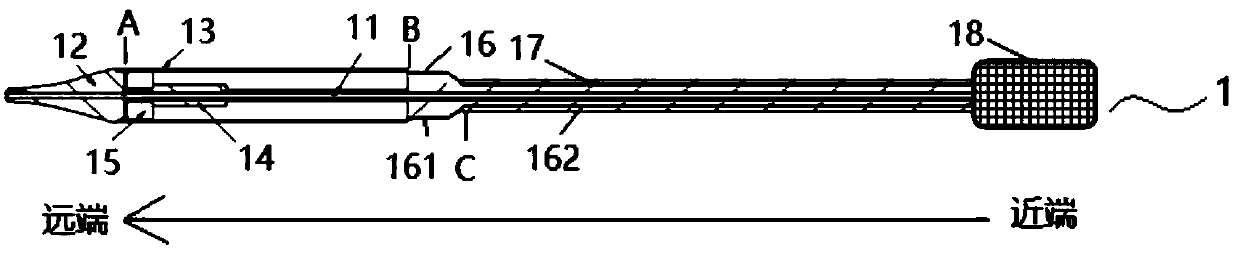

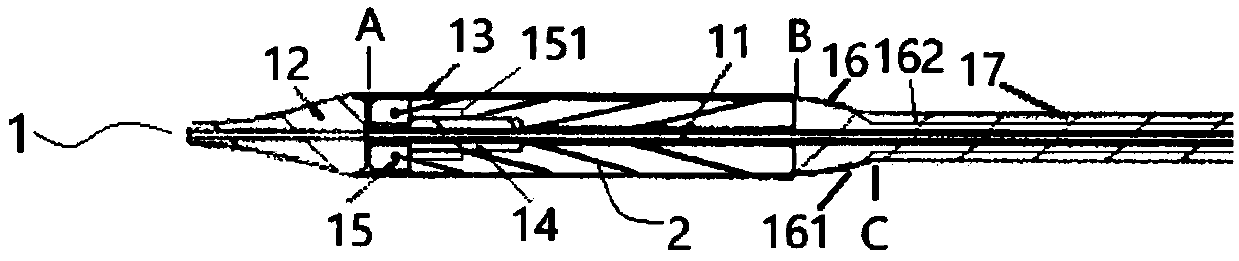

[0036] Such as figure 1 As shown, the delivery device 1 in this embodiment is composed of a catheter assembly and a handle 18 . Specifically, the catheter assembly includes: an inner core tube 11 , a guide head 12 , a sheath tube 13 , an inner tube 14 , a fixing head 15 , a transition part 16 and a bending control tube 17 .

[0037] Wherein, the proximal end of the inner core tube 11 is connected with the movable part of the inner core tube in the handle 18, so that the handle 18 can drive the axial movement of the inner core tube 11; in addition, the distal end of the inner core tube 11 is fixedly connected with the guide head 12 , the distal end of the sheath tube 13 is smoothly and fixedly connected to the proximal end of the guide head 12 at A, and the sheath tube 13 is sheathed outside the inner core tube 11 . In this way, after the inner core tube 11 is driven, it can drive the guide head 12 and the sheath tube 13 to move axially together.

[0038]Optionally, the guide...

Embodiment 2

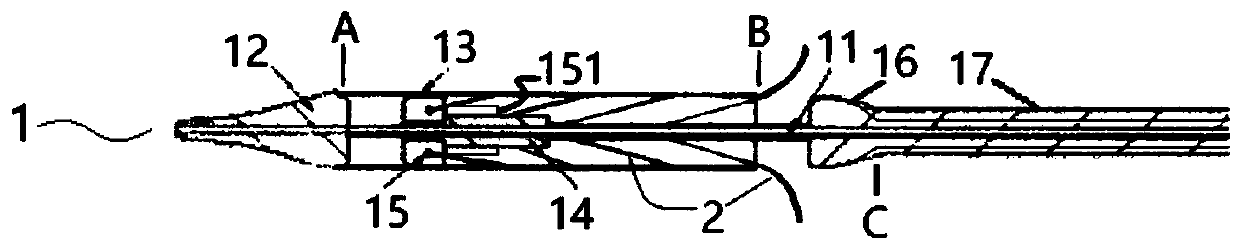

[0064]The transition part 16 in the first embodiment includes two parts, the transition part 161 and the conduit part 162 , which are connected to each other, and the structure is relatively complicated, and the implantation operation process of the implant body 2 is also relatively complicated. Based on this, if Figure 5 As shown, the transition part 16 has been modified in this embodiment, and another structure of the delivery device 1' for the implant is proposed.

[0065] Such as Figure 5 As shown, the transition part 16 in the present embodiment does not have the catheter part 162, only the transition part 161, in this case, the proximal end of the transition part 161 is directly and smoothly fixedly connected with the distal end of the bending control tube 17, through The axial movement of the bending control tube 17 controls the axial movement of the transition portion 161 . The structure of other parts of the delivery device 1' of the implant in this embodiment and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com