Preparation method of high-performance aluminum alloy blistering mold

A technology of plastic-absorbing mold and aluminum alloy, which is applied in the preparation of aluminum-alloy plastic-absorbing mold and high-performance aluminum-alloy plastic-absorbing mold. Low service life and other problems, to achieve the effect of improving demoulding efficiency and finished product quality, excellent self-lubricating performance, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

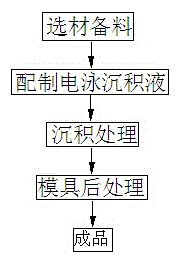

[0015] The specific preparation steps of the high-performance aluminum alloy blister mold mentioned in the present invention are as follows:

[0016] a) Material selection and preparation, the pretreatment process of the aluminum alloy mold includes: sandpaper grinding, degreasing treatment, water rinsing and drying, etc.; the sandpaper uses No. 1000 water sandpaper; the average particle diameter of the selected molybdenum disulfide particles is 2-2.5 um,

[0017] b) Preparation of electrophoretic deposition solution. The main components and percentage ratio of the electrophoretic deposition solution are: 7% molybdenum disulfide particles, 0.2% surfactant, and the rest is deionized water; triton solution is selected as the surfactant; The preparation process is as follows: Put the raw materials into the electromagnetic stirrer, control the rotation speed of the mixing drum at 400r / min, control the temperature of the mixing drum at about 35°C, and the time is about 1.2 hours; ...

Embodiment 2

[0021] The specific preparation steps of the high-performance aluminum alloy blister mold mentioned in the present invention are as follows:

[0022] a) Material selection and preparation, the pretreatment process of the aluminum alloy mold includes: sandpaper grinding, degreasing treatment, water rinsing and drying, etc.; the sandpaper uses No. 1000 water sandpaper; the average particle diameter of the selected molybdenum disulfide particles is 2-2.5 um,

[0023] b) Prepare the electrophoretic deposition solution, the main components and percentage ratio of the electrophoretic deposition solution are: 8% molybdenum disulfide particles, 0.25% surfactant, and the rest is deionized water; triton solution is selected as the surfactant; The preparation process is as follows: put the raw materials into the electromagnetic stirrer, control the rotation speed of the mixing drum at 450r / min, control the temperature of the mixing drum at about 35°C, and the time is about 1 hour;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com