BGA ball planting device and method

A technology of planting balls and solder balls, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. It can solve the problems of high BGA scrap rate, increase BGA cycle, and high recycling cost, so as to reduce costs and scrap rates. , speed up the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

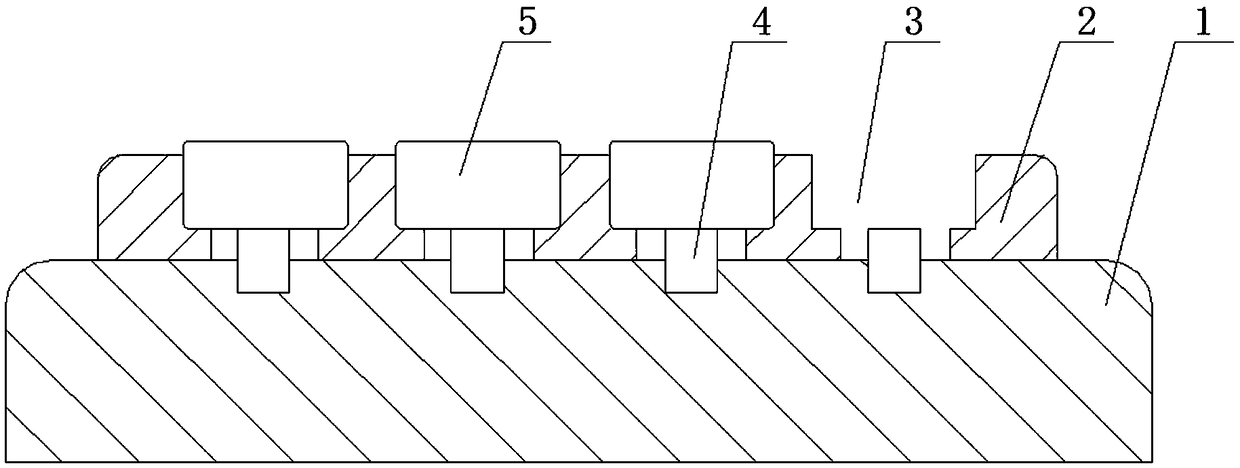

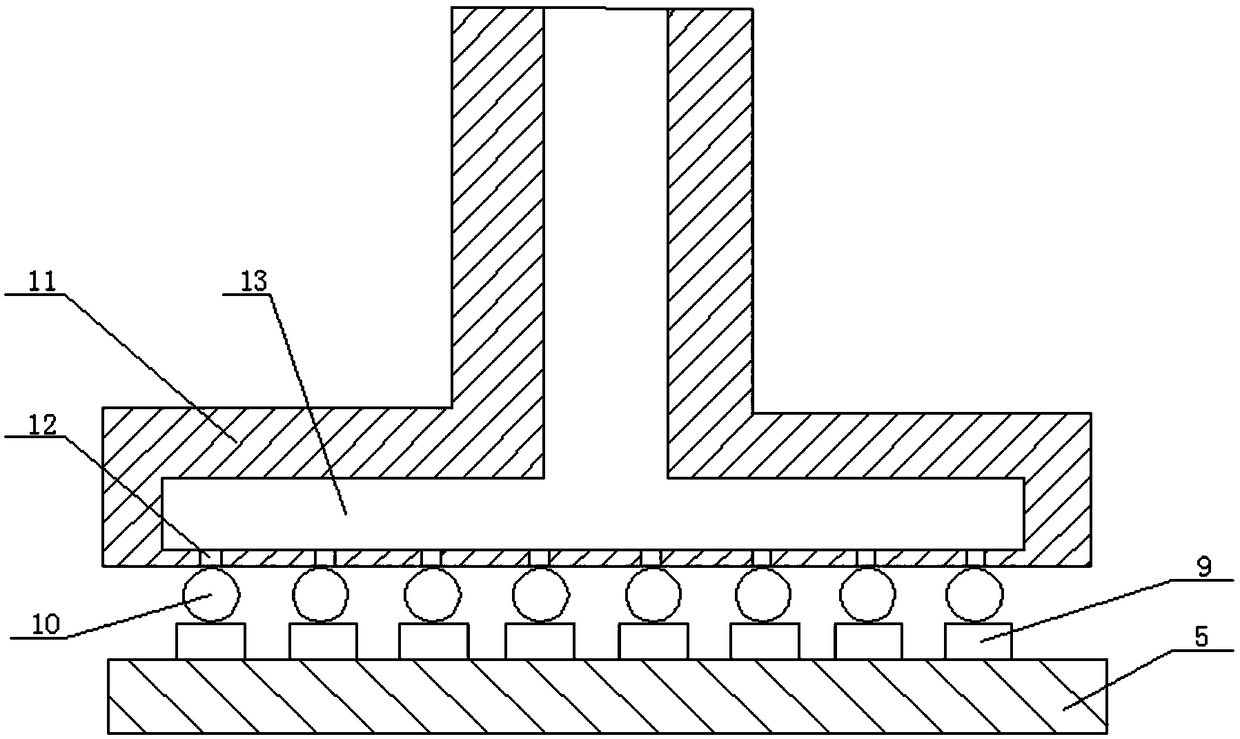

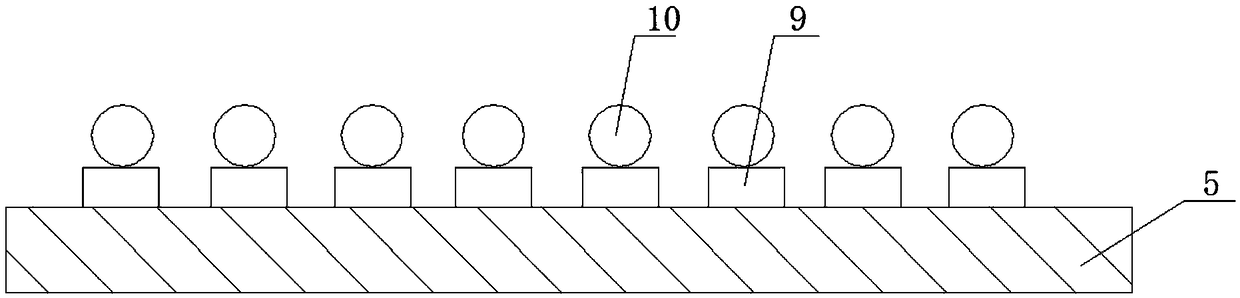

[0031] A BGA ball planting device, comprising a printing machine and a placement machine, the printing machine is provided with a printing fixture, the printing fixture includes a supporting base 1, and the supporting base 1 is provided with a support carrier 2, the The support carrier 2 is connected with the supporting base 1, and the support carrier 2 is provided with a groove 3, and the groove 3 is provided with a plurality of, and the cross-sectional shape of the groove 3 in the vertical direction is an inverted convex shape . A suction nozzle 4 is provided inside the groove 3 , the lower end of the suction nozzle 4 is connected to the support base 1 , and the upper end of the suction nozzle 1 sucks the lower surface of the BGA 5 . Because the support carrier 2 is provided with a plurality of grooves 3, and the plurality of grooves 3 can place a plurality of BGAs 5, so the printing fixture can realize simultaneous printing of a plurality of BGAs 5 at one time, thereby incr...

Embodiment 2

[0040] A BGA ball planting device, comprising a printing machine and a ball planting jig two, the printing machine is provided with a printing jig, and the printing jig includes a support base 1, and the support base 1 is provided with a support carrier 2, The supporting carrier 2 is connected with the supporting base 1, the supporting carrier 2 is provided with grooves 3, and the grooves 3 are provided with a plurality, and the cross-sectional shape of the grooves 3 in the vertical direction is inverted. convex. A suction nozzle 4 is provided inside the groove 3 , the lower end of the suction nozzle 4 is connected to the support base 1 , and the upper end of the suction nozzle 1 sucks the lower surface of the BGA 5 . Because the support carrier 2 is provided with a plurality of grooves 3, and the plurality of grooves 3 can place a plurality of BGAs 5, so the printing fixture can realize simultaneous printing of a plurality of BGAs 5 at one time, thereby increasing the printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com