Preparation method of fluorine-containing hydroxyphenyl organic acid alkenyl ester demoulding intermediate

A technology of fluorine-containing hydroxyphenyl and organic acids, which is applied in the field of mold release additive synthesis, can solve the problems of high-efficiency fluorine mold release agents relying on imports, and achieve improved mold release efficiency and product processing quality, good economic and social benefits, The effect of simple and easy reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

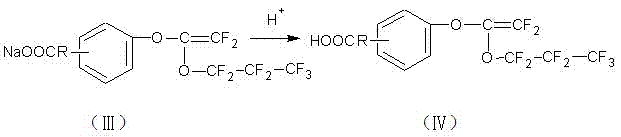

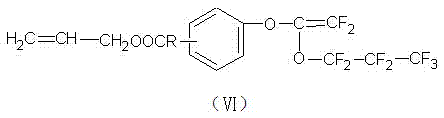

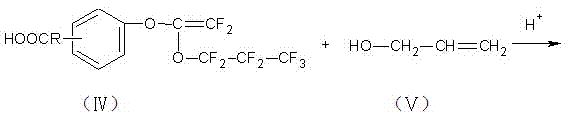

Method used

Image

Examples

Embodiment 1

[0023] In a four-neck flask equipped with a stirring device, a reflux condenser and a thermometer, add 100 mL of N,N-dimethylacetamide, 25 g of p-phenol acetic acid and 1.2 g of decarboxylated hexafluoropropylene oxide dimer, turn on the stirring, Slowly add 25 grams of triethylamine, keep the temperature of 25℃~35℃ in the water bath, carry out the nucleophilic substitution reaction for 6 hours, add 60mL of water to the four-neck flask to dilute the reaction material, and add the mass concentration of 20 under stirring. % Sodium hydroxide solution, adjust the pH value to about 10, filter, take the filtrate, slowly pour a dilute hydrochloric acid solution with a mass concentration of 20% into the filtrate under stirring, adjust the pH value to about 1.0, precipitate solid products, filter Then the filter cake was washed repeatedly with water and dried to obtain the hydroxyphenyl organic acid substituted by the decarboxylated hexafluoropropylene oxide dimer, and the hydroxyphenyl ...

Embodiment 2

[0025] In a four-neck flask equipped with a stirring device, a reflux condenser and a thermometer, add 100 mL of N,N-dimethylacetamide, 30 grams of p-phenol propionic acid and 60 grams of decarboxylated hexafluoropropylene oxide dimer, and turn on the stirring , Slowly add 1.8 g of triethylamine, keep the temperature of 25℃~35℃ in the water bath, carry out the nucleophilic substitution reaction for 7 hours, add 60mL of water to the four-neck flask to dilute the reaction material, add the mass concentration of 20% sodium hydroxide solution, adjust the pH value to about 10, filter, take the filtrate, slowly pour a dilute hydrochloric acid solution with a mass concentration of 20% into the filtrate under stirring, adjust the pH value to about 1.0, and precipitate a solid product. After filtration, the filter cake was washed repeatedly with water and dried to obtain decarboxylated hexafluoropropylene oxide dimer substituted hydroxyphenyl organic acid, and decarboxylated hexafluoropr...

Embodiment 3

[0027] In a four-neck flask equipped with a stirring device, a reflux condenser and a thermometer, add 100 mL of N,N-dimethylacetamide, 20 grams of m-phenolic acid and 50 grams of decarboxylated hexafluoropropylene oxide dimer, turn on the stirring, Slowly add 1.0 g of triethylamine, keep the temperature of 25℃~35℃ in the water bath, carry out the nucleophilic substitution reaction for 5 hours, add 60mL water to the four-neck flask to dilute the reaction material, and add the mass concentration of 20 under stirring. % Sodium hydroxide solution, adjust the pH value to about 10, filter, take the filtrate, slowly pour a dilute hydrochloric acid solution with a mass concentration of 20% into the filtrate under stirring, adjust the pH value to about 1.0, precipitate solid products, filter Then the filter cake was washed repeatedly with water and dried to obtain the hydroxyphenyl organic acid substituted by the decarboxylated hexafluoropropylene oxide dimer, and the hydroxyphenyl orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com