Ultraviolet-cured aluminum formwork release agent with high number of turnover times and preparation method of ultraviolet-cured aluminum formwork release agent

A technology of ultraviolet light and aluminum template, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of coating pollution, low cycle turnover, high energy consumption of film formation, etc., achieve energy saving, convenient on-site operation, and no three wastes pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

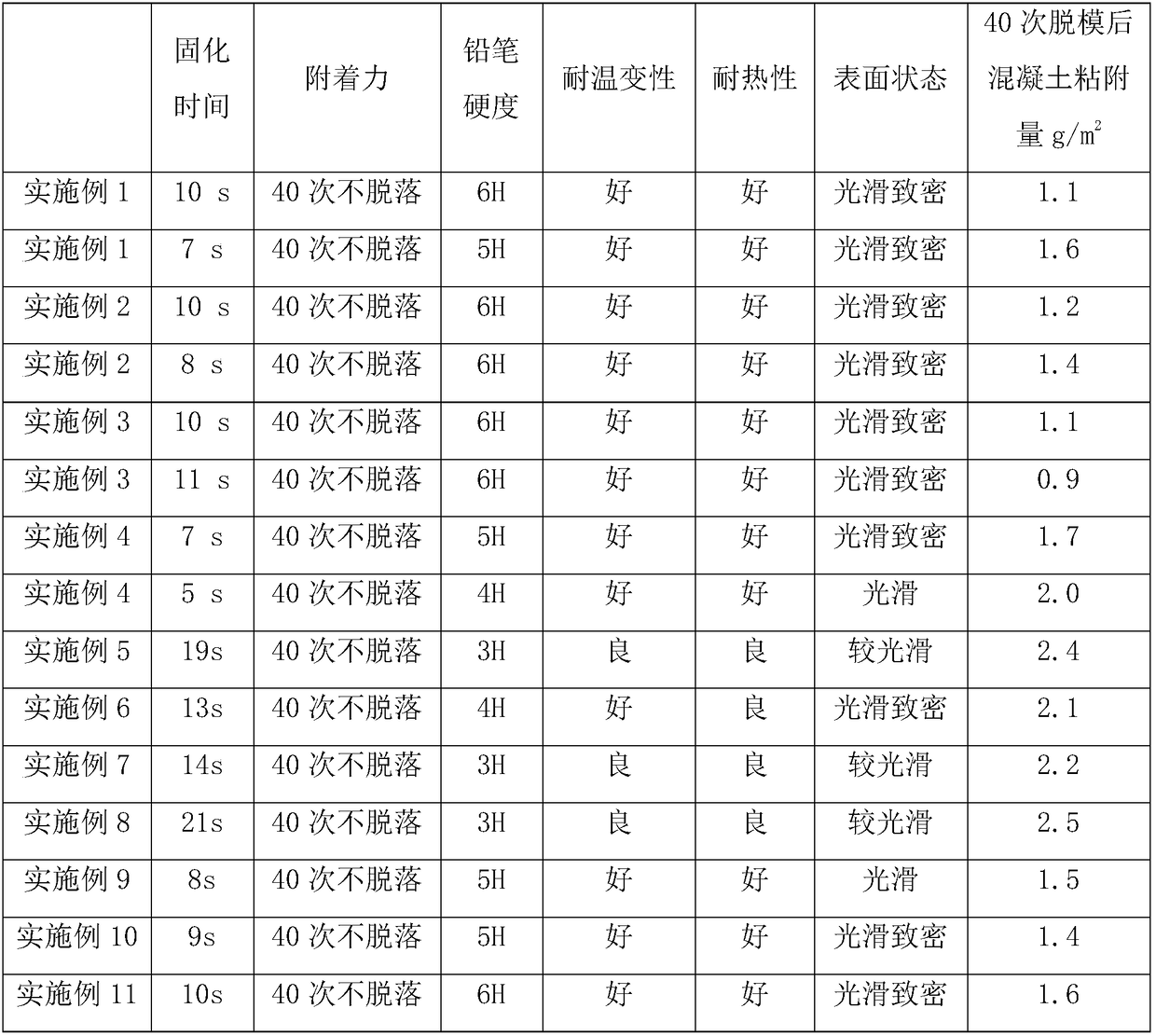

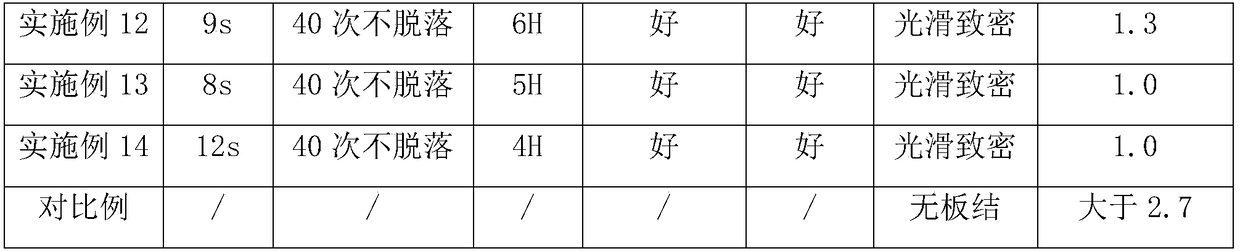

Examples

Embodiment 1

[0028] Weigh 1 part of acrylic acid, 2 parts of hydroxyethyl acrylate, 2 parts of isophthalic acid, 4 parts of phthalic anhydride, 1 part of trimellitic anhydride, 1 part of epichlorohydrin, 2 parts of ethylene glycol diglycidyl ether, epoxy resin Add 3 parts into a three-necked flask equipped with stirring, heating and cooling devices, heat and stir, control the temperature in the reactor to 80-130°C, stop heating when the acid value is less than 1mg KOH / g and cool to room temperature to obtain the modified permanent acrylic epoxy resin.

[0029] Raise the temperature of the stainless steel reaction kettle equipped with a disc dispersion stirring device to 30°C, add 7 parts of modified acrylic epoxy resin, 2 parts of UV monomer diluent pentaerythritol triacrylic acid monomer diluent, adhesion promoter A 0.5 part of hydroxyethyl acrylate phosphate, 0.5 part of leveling agent MONENG-1153, 0.3 part of surface slip agent GWN-N, ultraviolet photoinitiator (2,4,6-trimethylbenzoyl) ...

Embodiment 2

[0031] Weigh 2 parts of acrylic acid, 3 parts of hydroxyethyl acrylate, 1 part of isophthalic acid, 5 parts of phthalic anhydride, 1 part of trimellitic anhydride, 2 parts of epichlorohydrin, 1 part of ethylene glycol diglycidyl ether, epoxy resin Add 3 parts into a three-necked flask equipped with stirring, heating and cooling devices, heat and stir, control the temperature in the reactor to 80-130°C, stop heating when the acid value is less than 1mg KOH / g and cool to room temperature to obtain the modified modified acrylic epoxy resin.

[0032] Heat the stainless steel reaction kettle equipped with a disc dispersion stirring device to 40°C, add 7 parts of modified acrylic epoxy resin, 2 parts of UV monomer diluent trimethylolpropane triacrylate, adhesion promoter 0.5 parts of ethylene glycol diglycidyl ether dimethacrylate phosphate, 0.5 parts of leveling agent XYS-5630A, 0.3 parts of surface slip agent GWC-L, ultraviolet photoinitiator 2-hydroxy-methyl-1- 0.5 parts of phen...

Embodiment 3

[0034] Weigh 2 parts of acrylic acid, 3 parts of hydroxyethyl acrylate, 2 parts of isophthalic acid, 4 parts of phthalic anhydride, 2 parts of trimellitic anhydride, 2 parts of epichlorohydrin, 2 parts of ethylene glycol diglycidyl ether, epoxy resin Add 4 parts into a three-necked flask equipped with stirring, heating and cooling devices, heat and stir, control the temperature in the reactor to 80-130°C, stop heating when the acid value is less than 1mg KOH / g and cool to room temperature to obtain the modified permanent acrylic epoxy resin.

[0035] Raise the temperature of the stainless steel reaction kettle equipped with a disc dispersion stirring device to 50°C, add 8 parts of modified acrylic epoxy resin, 1 part of UV monomer diluent hexanediol diacrylate, (meth)acrylic acid iso 1 part of bornyl ester, 0.5 part of adhesion promoter glyceryl dimethacrylate phosphate, 0.5 part of leveling agent BYK-306, 0.3 part of surface slip agent GWA-L, 0.3 part of ultraviolet photoinit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com