Method of synthesizing a fluorine-containing demoulding additive with agricultural processing side product cardanol

A release additive and agricultural processing technology, applied in additives, petroleum industry, lubricating composition, etc., can solve the problems of high-efficiency fluorine release agent dependence on imports, etc., to improve release efficiency and product processing quality, sufficient source of raw materials, Effects that meet high-end needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

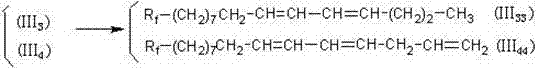

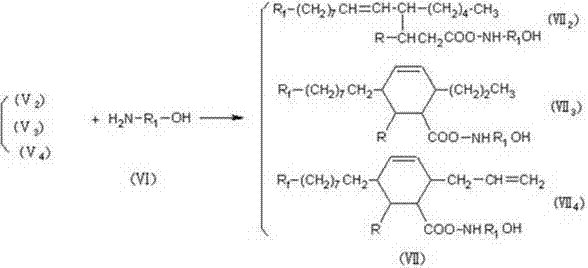

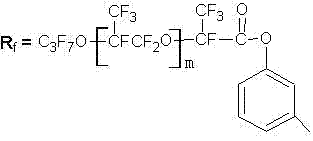

Method used

Image

Examples

Embodiment 2

[0031] In a four-neck flask equipped with a stirring device, a reflux condensing device, and a thermometer, add 100 mL of acetone, 30 g of cardanol, and 51 g of hexafluoropropylene oxide oligomer, start stirring, and slowly add 2.0 g of N,N-dimethyl Hexylcyclohexylamine, kept in an oil bath at a temperature of 20°C to 30°C, after a nucleophilic substitution reaction for 8 to 9 hours, the acetone was evaporated to obtain a fluorine-containing mixed phenol product substituted by a hexafluoropropylene oxide oligomer , and then add 2 grams of sulfuric acid to the four-necked bottle, heat up to 85°C to 95°C and keep it for 1 to 2 hours, then add 9.6 grams of 2-valeric acid, 1.5 grams of p-benzoquinone and 1.0 grams of methane to the four-necked bottle Sulfonic acid, continue to heat up to 175 ° C ~ 185 ° C for 8 hours, lower the temperature, dilute the reactant with dilute sodium hydroxide solution, filter, take the filtrate, and generate the product, add 25 grams of monoethanolamin...

Embodiment 3

[0033]In a four-necked flask equipped with a stirring device, a reflux condensing device and a thermometer, add 100 mL of acetone, 35 g of cardanol and 54 g of hexafluoropropylene oxide oligomer, start stirring, and slowly add 1.5 g of N-ethylmorpholine , kept in an oil bath at a temperature of 25°C to 35°C, carried out a nucleophilic substitution reaction for 7 to 8 hours, then distilled off the acetone to obtain a fluorine-containing mixed phenol product substituted by a hexafluoropropylene oxide oligomer, and then added to four Add 3 grams of sulfuric acid into the bottle, heat up to 85°C-95°C and keep it for 1-2 hours, then add 9.8 grams of trans-crotonic acid, 2.0 grams of p-benzoquinone and 1.4 grams of methanesulfonic acid into the four-necked bottle, Continue to raise the temperature to 185°C to 195°C to react for 7 hours, lower the temperature, dilute the reactant with dilute sodium hydroxide solution, filter, take the filtrate, and generate the product, add 26 grams o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com