Hydroxy-containing multi-sulfonated ricinoleate and preparation method thereof

A polysulfonated castor and oleate technology, which is applied in the direction of sulfuric acid ester preparation, organic chemistry, petroleum industry, etc., can solve the problems of application limitation, poor lubricity, stability and corrosion resistance, and achieve low cost and good Water solubility and stability, the effect of sufficient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

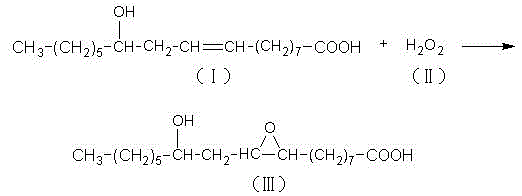

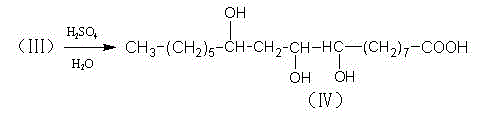

Method used

Image

Examples

Embodiment 1

[0017] In the there-necked flask equipped with stirring device, reflux condensing device and thermometer, add 100 grams of ricinoleic acid, 12 grams of acetic acid and 0.5 gram of cation exchange resin, under the catalysis of 1.2 grams of concentrated sulfuric acid, drop 34.2 grams of hydrogen peroxide, in At a temperature of 60°C to 80°C, carry out epoxidation reaction for 2 to 4 hours to generate epoxidized ricinoleic acid, stop the reaction, put the reaction material in 4 to 5 times the volume of hot water for hydrolysis, separate liquid, and use warm water Wash the product, take the oil layer, and obtain the hydrolyzed product trihydroxyricinoleic acid. The trihydroxyricinoleic acid is placed in a reaction flask in an ice-water bath, and 90 grams of concentrated sulfuric acid is added dropwise, stirred, and the sulfonation reaction is carried out for 1 to 2 hours. Generate hydroxyl-containing polysulfonated ricinoleic acid, and finally neutralize and wash with saturated sod...

Embodiment 2

[0019] In the there-necked flask equipped with stirring device, reflux condensing device and thermometer, add 95 grams of ricinoleic acid, 10 grams of acetic acid and 0.5 grams of cation exchange resin, under the catalysis of 1.1 grams of concentrated sulfuric acid, drop 35.6 grams of hydrogen peroxide, in At a temperature of 60°C to 80°C, carry out epoxidation reaction for 2 to 4 hours to generate epoxidized ricinoleic acid, stop the reaction, put the reaction material in 4 to 5 times the volume of hot water for hydrolysis, separate liquid, and use warm water Wash the product, take the oil layer, and obtain the hydrolyzed product trihydroxyricinoleic acid. The trihydroxyricinoleic acid is placed in a reaction flask in an ice-water bath, and 80 grams of concentrated sulfuric acid is added dropwise, stirred, and the sulfonation reaction is carried out for 1 to 2 hours. Generate hydroxyl-containing polysulfonated ricinoleic acid, and finally neutralize and wash with saturated sod...

Embodiment 3

[0021] In the there-necked flask equipped with stirring device, reflux condensing device and thermometer, add 90 grams of ricinoleic acid, 9 grams of acetic acid and 0.5 gram of cation exchange resin, under the catalysis of 1 gram of concentrated sulfuric acid, drop 35 grams of hydrogen peroxide, and At a temperature of 60°C to 80°C, carry out epoxidation reaction for 2 to 4 hours to generate epoxidized ricinoleic acid, stop the reaction, put the reaction material in 4 to 5 times the volume of hot water for hydrolysis, separate liquid, and use warm water Wash the product, take the oil layer, and obtain the hydrolyzed product trihydroxyricinoleic acid. The trihydroxyricinoleic acid is placed in a reaction flask in an ice-water bath, and 70 grams of concentrated sulfuric acid is added dropwise, stirred, and the sulfonation reaction is carried out for 1 to 2 hours. Generate hydroxyl-containing polysulfonated ricinoleic acid, and finally neutralize and wash with saturated sodium bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com