Preparation method and application of copper metal organic framework derived porous carbon composite material

A technology of organic framework and composite materials, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, water treatment of special compounds, etc., to achieve low production cost, strong catalytic degradation ability, and sufficient source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

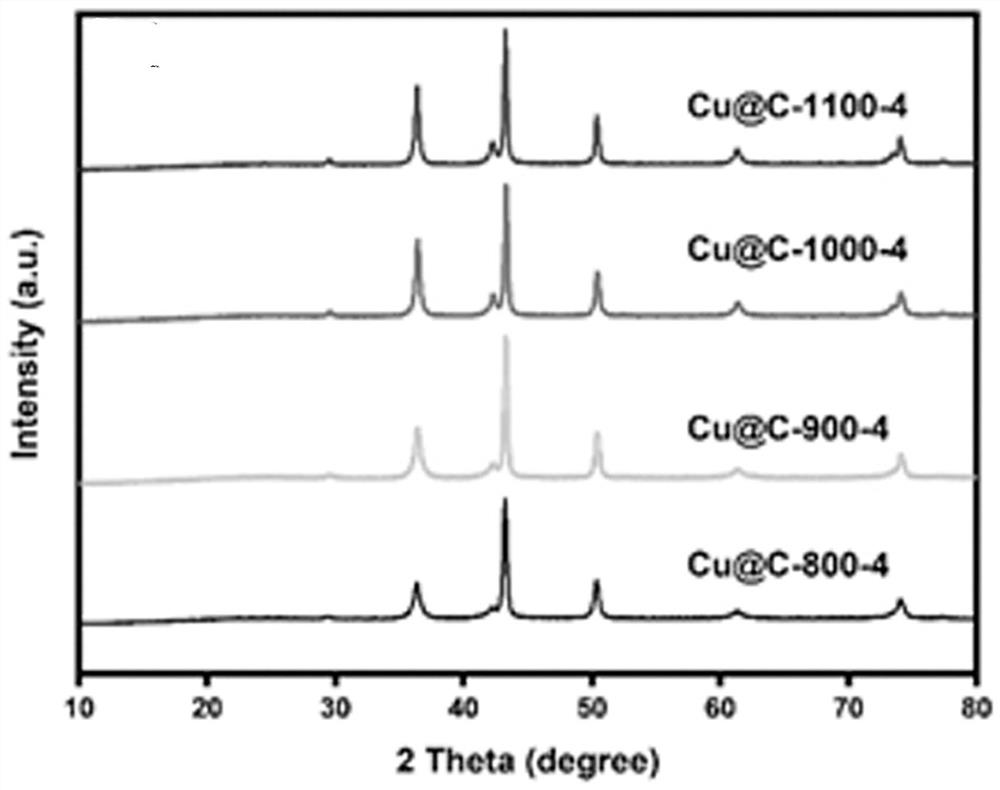

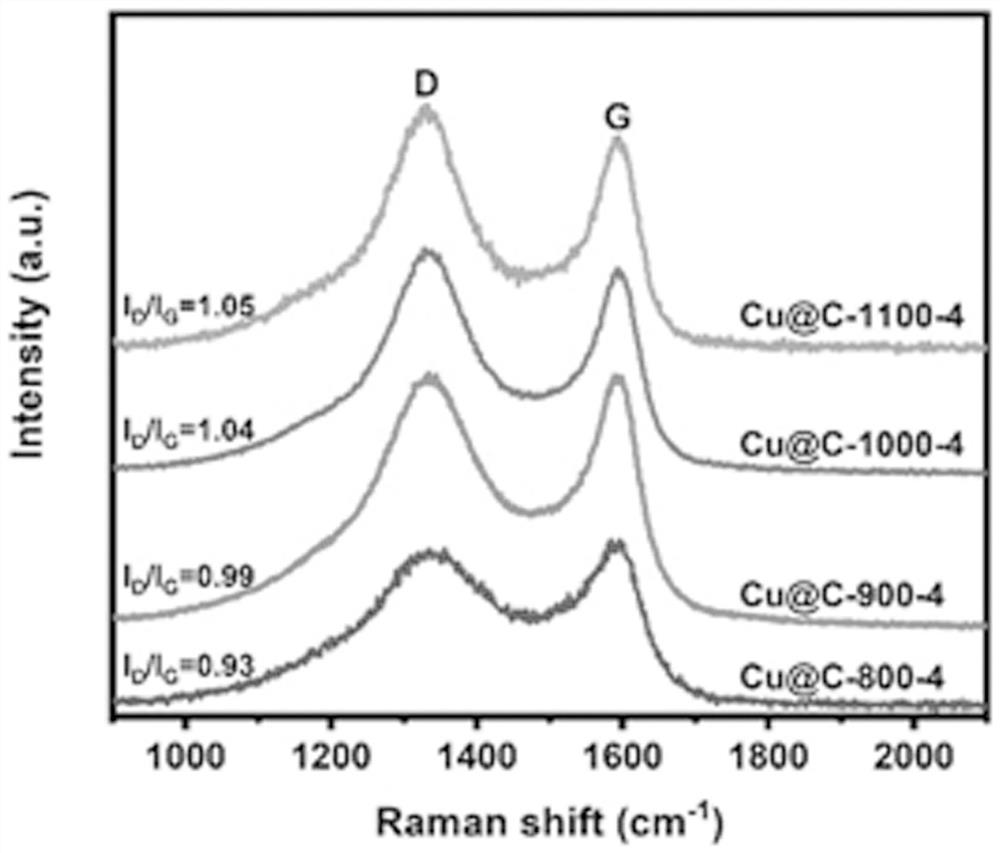

[0042] Preparation of Porous Carbon Composite Material Cu@C-800-4 Derived from Copper Metal Organic Framework

[0043] 1) Dissolve 0.05mmol of 4-21 ligand and 0.10mol of copper (II) trifluoromethanesulfonate in 10mL of acetonitrile, and stir at room temperature for 20min to form a mixed solution A, then add 20μL of triethylamine dropwise to mix In solution A, shake evenly to obtain mixed solution B; place the vial containing mixed solution B in a drying oven with a temperature of 80°C for 24 hours to react for 24 hours, after natural cooling, filter out crystal C with filter paper, and dry naturally at room temperature to obtain Copper metal organic framework compound MOF;

[0044] 2) Put the crucible containing the copper metal-organic framework compound MOF into a tubular muffle furnace for calcination at a calcination temperature of 800°C for 4 hours, wherein the tubular muffle furnace maintains a heating rate of 5°C during the heating process / min, nitrogen gas was introd...

Embodiment 2

[0046] Preparation of porous carbon composite material Cu@C-900-4 derived from copper metal organic framework

[0047] 1) Dissolve 0.05mmol of 4-21 ligand and 0.10mol of copper (II) trifluoromethanesulfonate in 10mL of acetonitrile, and stir at room temperature for 20min to form a mixed solution A, then add 20μL of triethylamine dropwise to mix In solution A, shake evenly to obtain mixed solution B; place the vial containing mixed solution B in a drying oven with a temperature of 80°C for 24 hours to react for 24 hours, after natural cooling, filter out crystal C with filter paper, and dry naturally at room temperature to obtain Copper metal organic framework compound MOF;

[0048] 2) Put the crucible containing the copper metal organic framework compound MOF into a tubular muffle furnace for calcination at a calcination temperature of 900°C for 4 hours, wherein the tubular muffle furnace maintains a heating rate of 5°C during the heating process / min, nitrogen gas was introd...

Embodiment 3

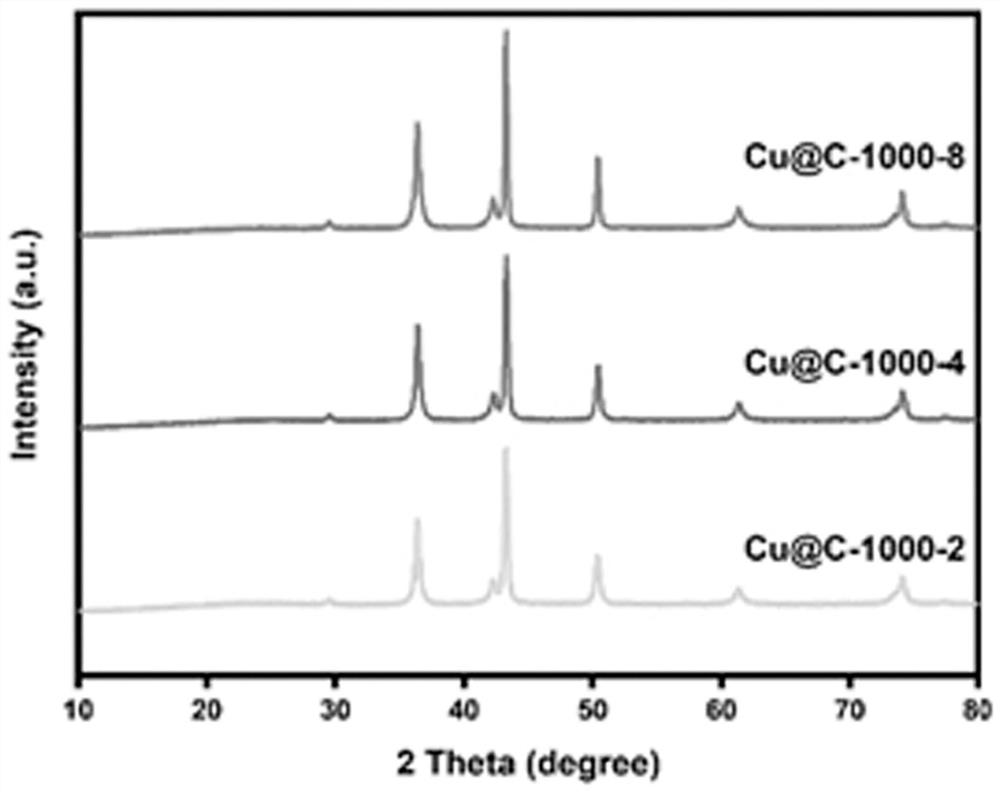

[0050] Preparation of Porous Carbon Composite Material Cu@C-1000-4 Derived from Copper Metal Organic Framework

[0051] 1) Dissolve 0.05mmol of 4-21 ligand and 0.10mol of copper (II) trifluoromethanesulfonate in 10mL of acetonitrile, and stir at room temperature for 20min to form a mixed solution A, then add 20μL of triethylamine dropwise to mix In solution A, shake evenly to obtain mixed solution B; place the vial containing mixed solution B in a drying oven with a temperature of 80°C for 24 hours to react for 24 hours, after natural cooling, filter out crystal C with filter paper, and dry naturally at room temperature to obtain Copper metal organic framework compound MOF;

[0052] 2) Put the crucible containing the copper metal organic framework compound MOF into a tubular muffle furnace for calcination at a calcination temperature of 1000°C for 4 hours, wherein the tubular muffle furnace maintains a heating rate of 5°C during the heating process / min, nitrogen gas was intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com