Injection mold cooling system facilitating demolding

A technology of injection molds and cooling systems, applied in the field of injection molds, can solve the problems of reducing processing efficiency, patterns, deformation of plastic products, etc., and achieve the effects of improving production efficiency, improving demoulding quality, and accelerating cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

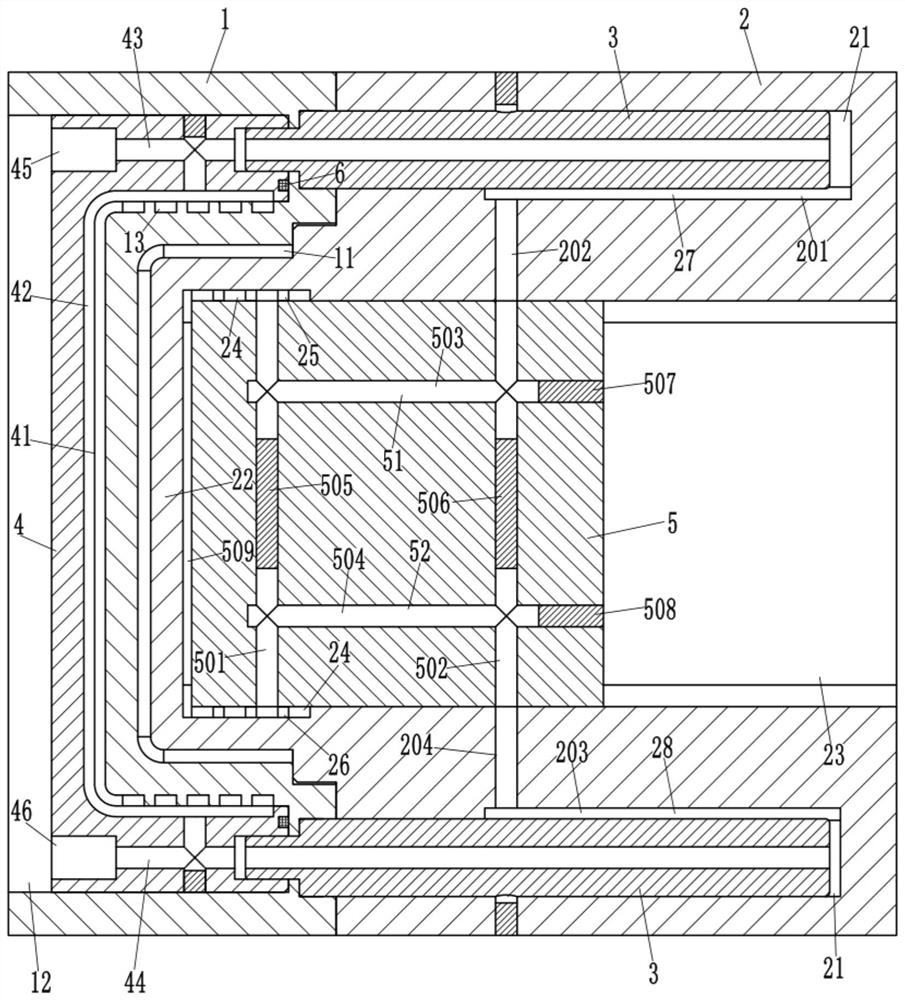

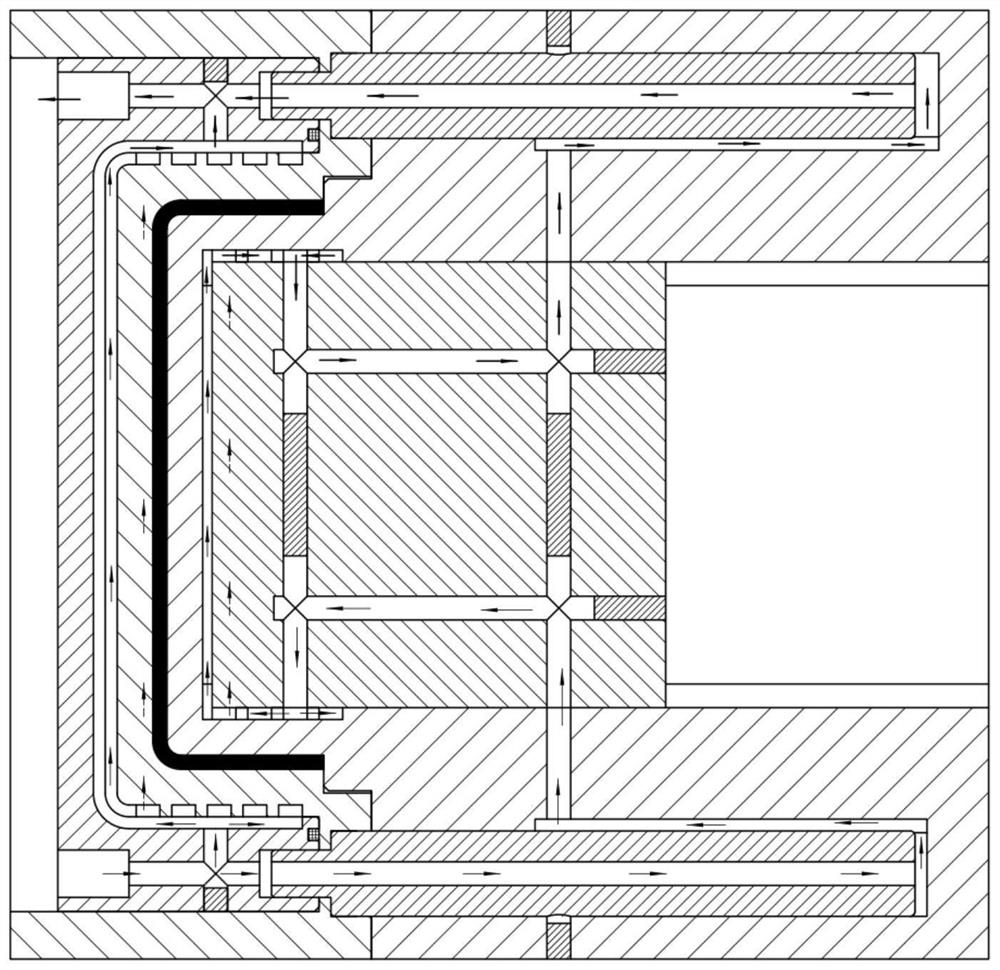

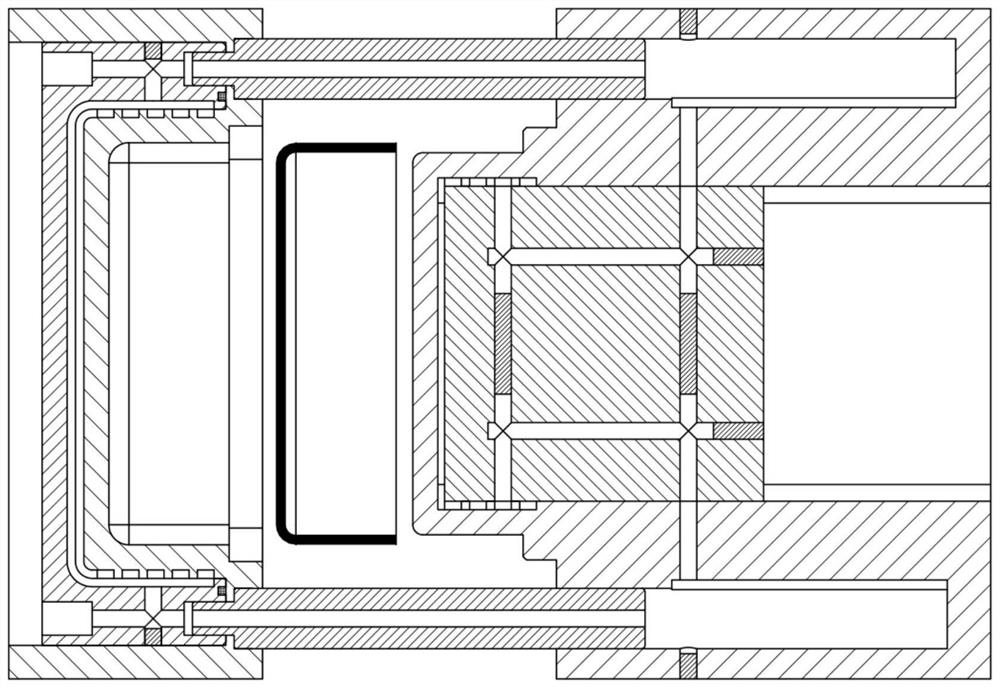

[0026] Examples such as Figure 1 to Figure 3 As shown, an injection mold cooling system for easy demoulding includes a concave mold 1 and a convex mold 2 arranged on the left and right. The concave mold 1 is fixed with two guide tubes 3 arranged up and down, and the guide tubes 3 are inserted into the convex mold. In the guide hole 21 of the mold 2;

[0027] The die 1 is formed with a cavity 11 with a right opening and a first cooling cavity 12 with a left opening. The outer wall of the cavity 11 is formed with a plurality of first annular grooves 13. Inside the first cooling cavity 12 A cooling water turning part 4 is fixed, and a groove 41 matching the outer wall of the cavity 11 is formed in the cooling water turning part 4, and a U-shaped sinking groove 42 is formed in the groove 41;

[0028] The water outlet main channel 43 and the water inlet main channel 44 which are arranged up and down and communicate with the U-shaped sinker 42 are formed in the cooling water trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com