Gripper

A clamping jaw and body technology, which is applied in the field of clamping devices for clamping multi-cavity injection molded parts, can solve the problems of low demoulding quality, fracture, and deformation of molded parts, and achieve the effect of improving the demoulding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

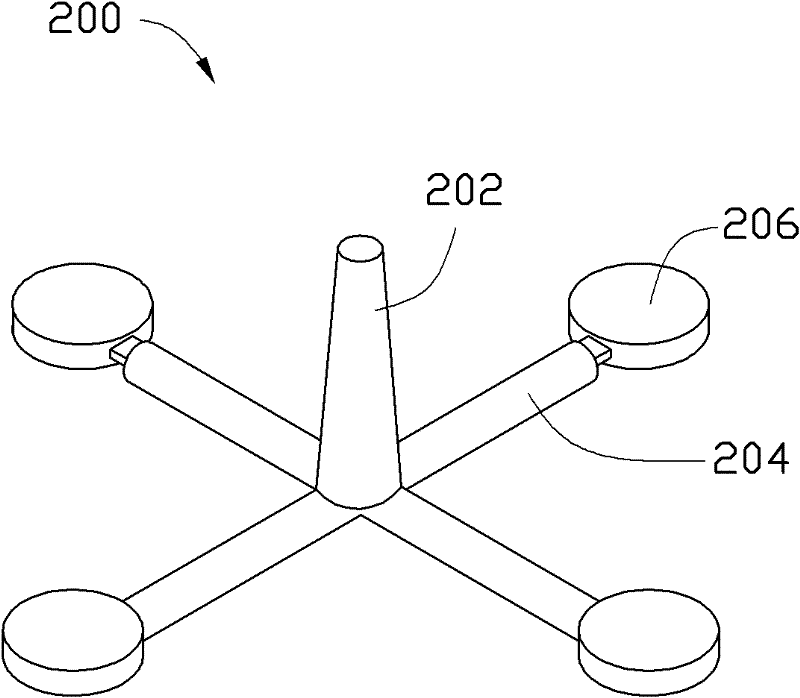

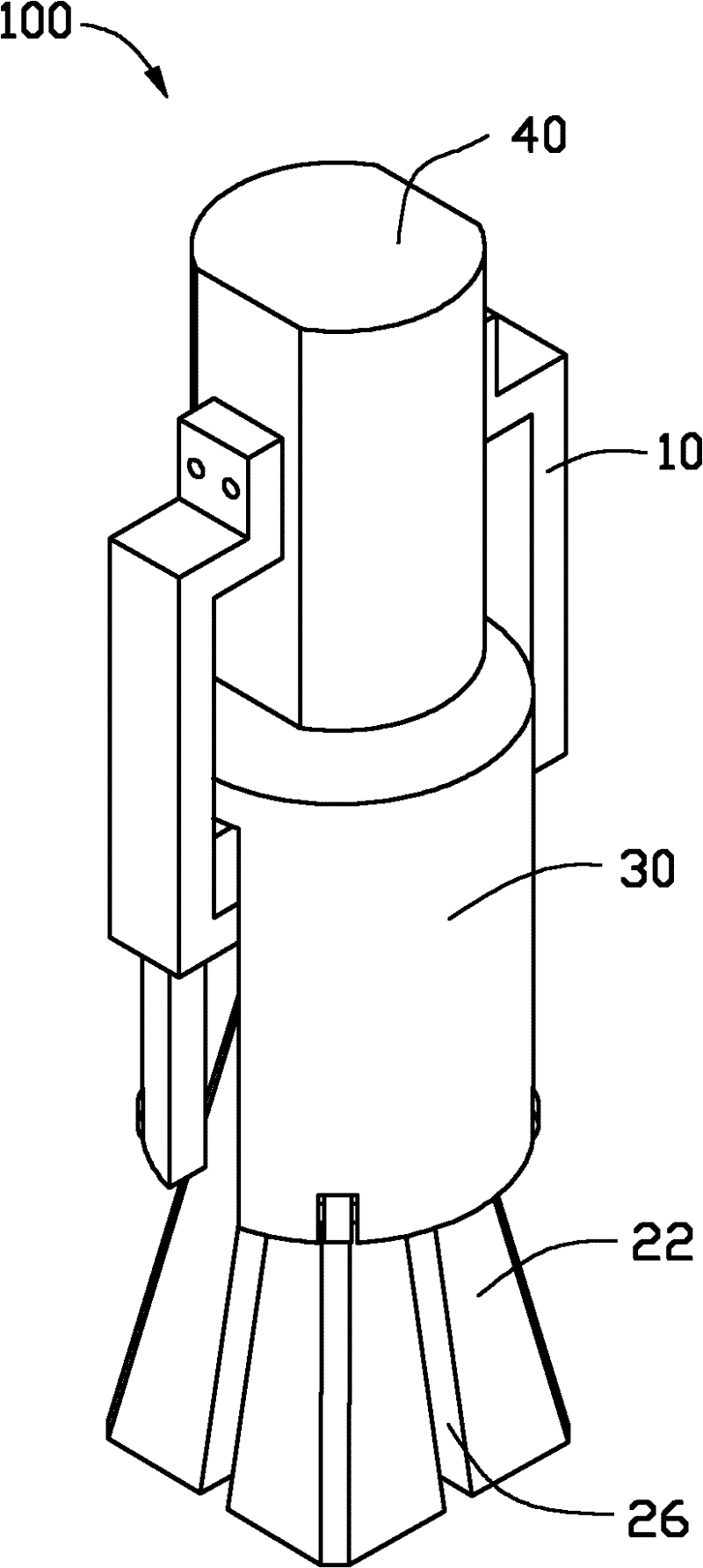

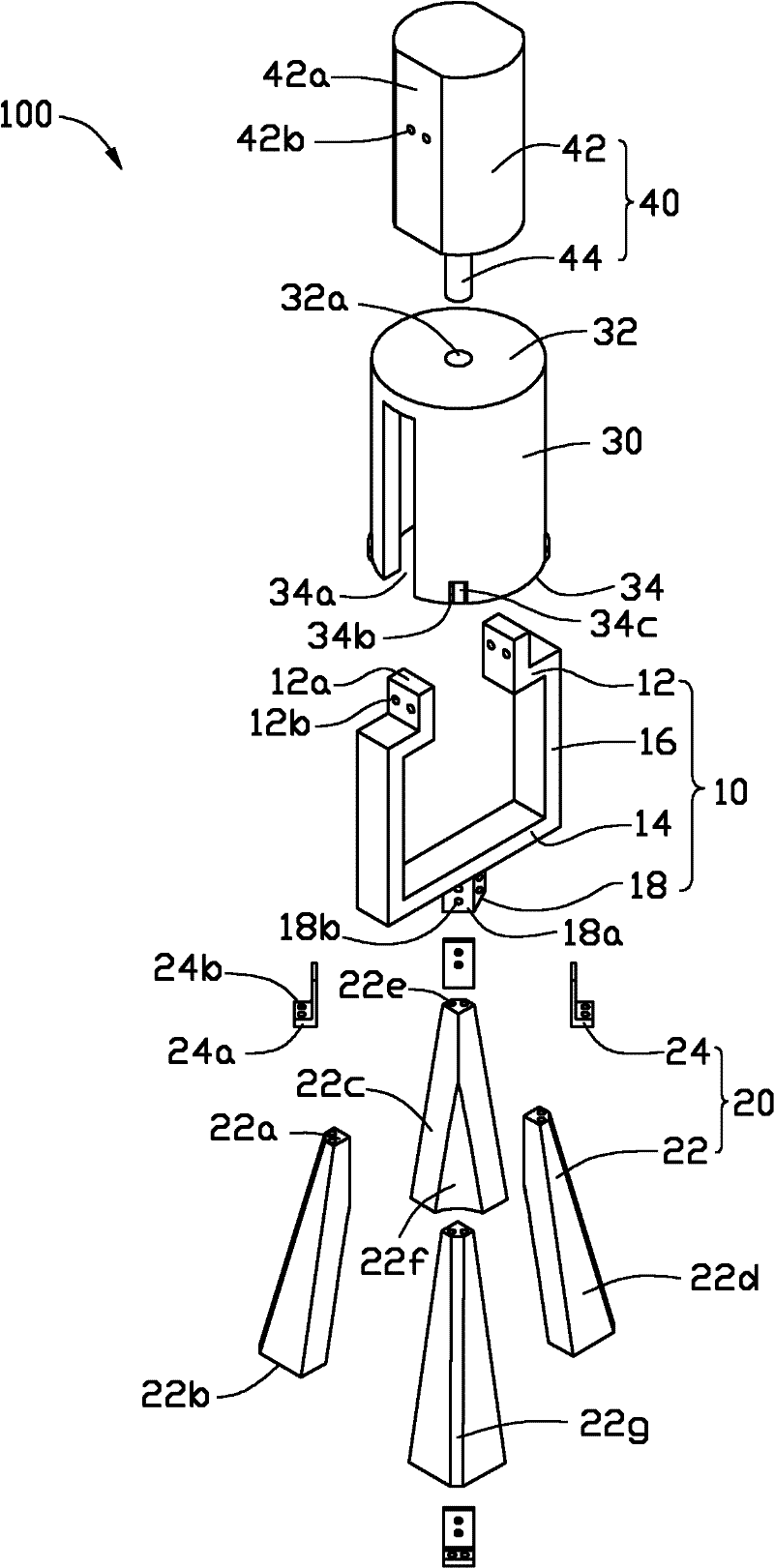

[0050] see Figure 1 to Figure 4 , the clamping device 100 of the preferred embodiment of the present invention is used to clamp a four-cavity lens forming part 200 for demoulding. The lens forming part 200 includes a material rod 202, four connecting rods 204 extending radially and equiangularly (90°) from the end of the material rod 202 and four lenses 206 ( Formed in the cavity (cavity) of the mold (not shown in the figure).

[0051] The clamping device 100 includes a fixed frame 10 , a plurality of jaws 20 , a sleeve 30 and a linear driving device 40 . Each jaw 20 includes a jaw body 22 and an elastic element 24 for fixing the jaw body 22 to the fixed frame 10 . A plurality of jaw bodies 22 are distributed in bundles. A gap 26 for accommodating a corresponding connecting rod 204 exists between every two adjacent jaw bodies 22 . The sleeve 30 is inserted into the plurality of jaw bodies 22 from one side of the plurality of elastic elements 24 and constrains the pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com