Method for producing linear alpha-olefins (LAOs) through Fischer-Tropsch synthesis of solvent phase

A Fischer-Tropsch synthesis and solvent-phase technology, applied in the preparation of liquid hydrocarbon mixtures, hydrocarbon production from carbon oxides, organic chemistry, etc., can solve the difficulties of supercritical solvent separation and circulation, the prospect of industrialization is not clear, and increase process compression Power consumption and other issues, to achieve the effect of low production cost, wide application range, or modulation of the secondary reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

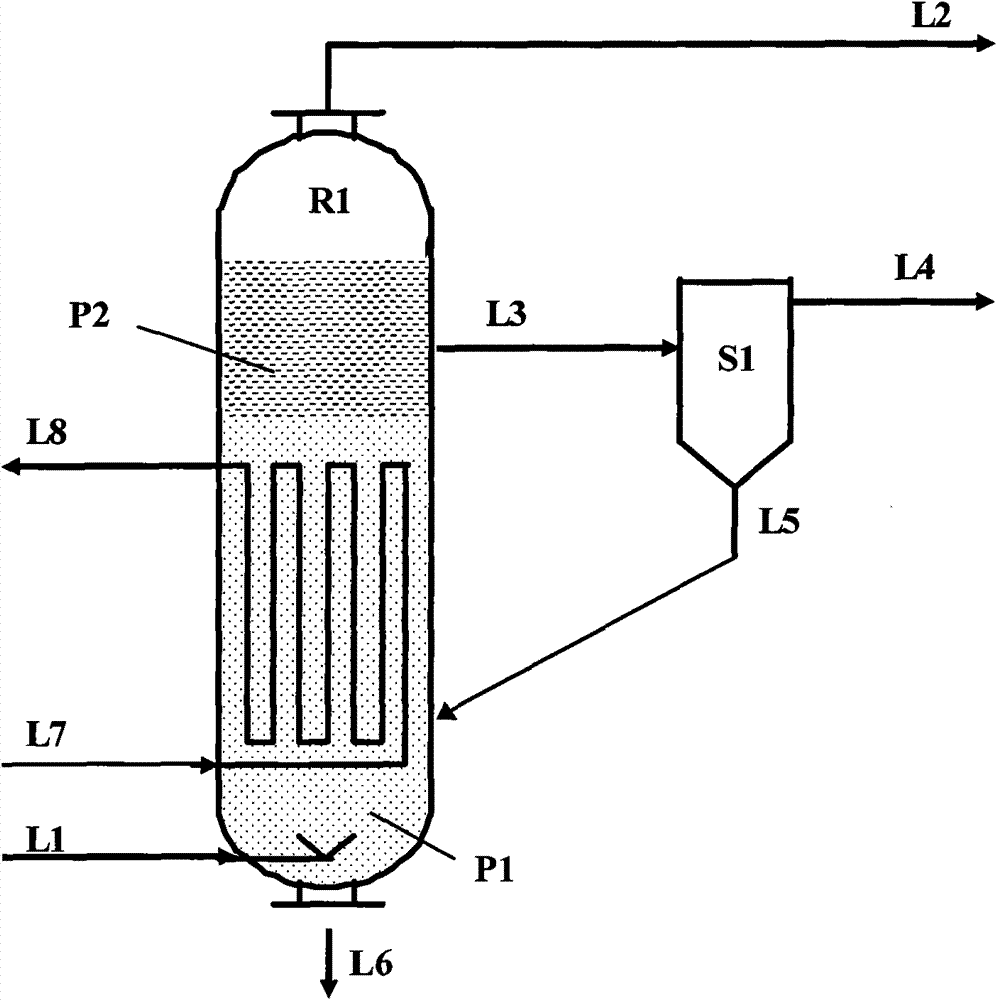

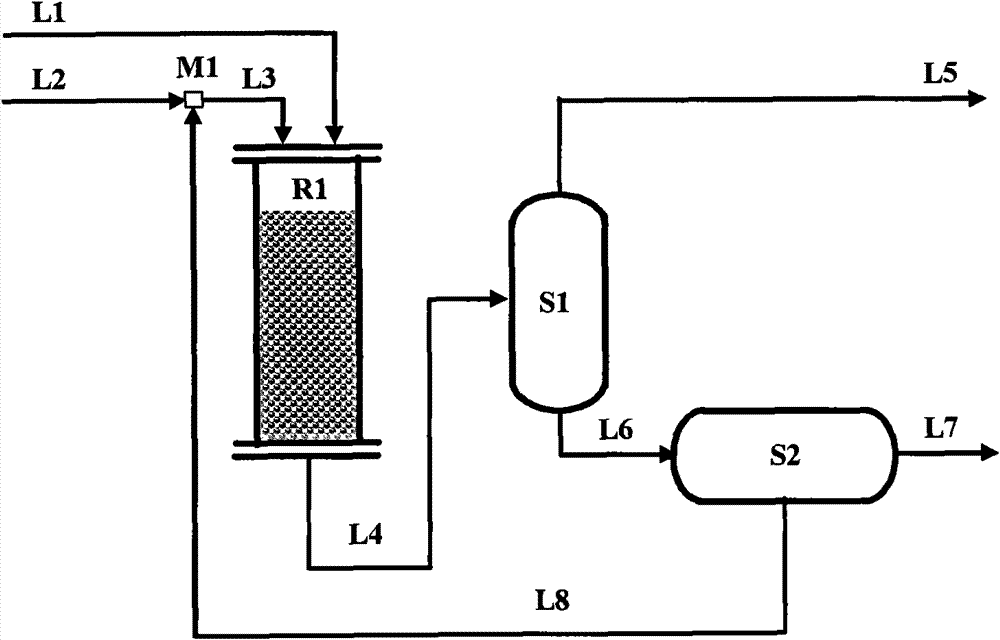

Method used

Image

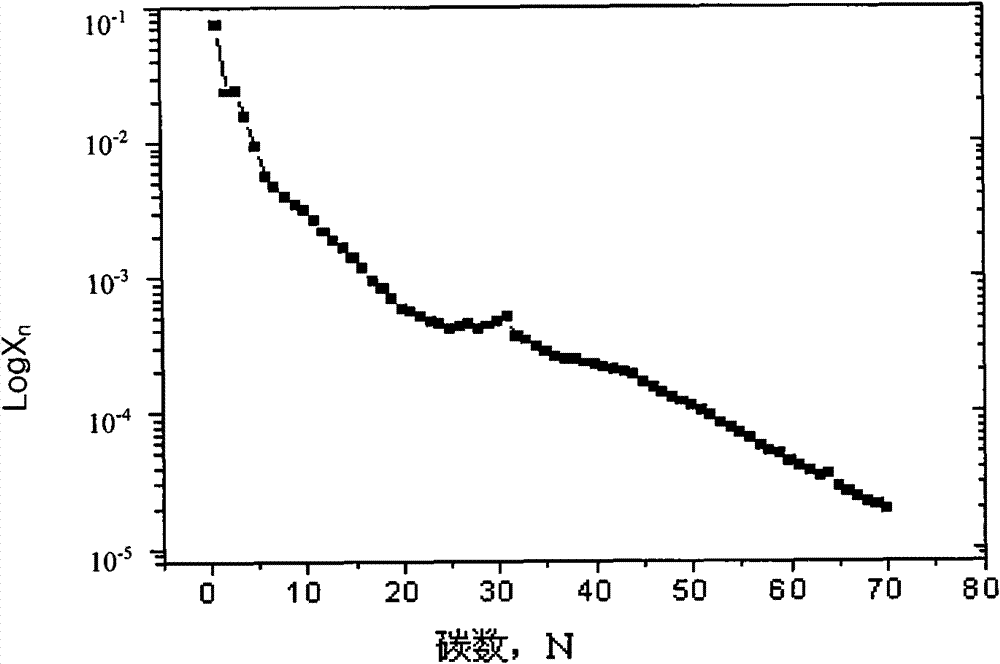

Examples

Embodiment 1

[0094] Weigh 1.00 g of the Fischer-Tropsch synthesis industrial Fe-based catalyst (with a particle size of 0.2-0.5 mm), pour it into a quartz tube reactor with quartz wool sealed in the middle, then seal the other end of the catalyst with quartz wool, and then place the reactor Put it into the resistance furnace, and connect the gas inlet and outlet pipelines. The reaction temperature is set to 230°C, and the space velocity is set to 3000h -1 , pressure 1atm, synthesis gas H 2 / CO is 2.0 to start reverting. After 20 hours of reduction, the temperature began to drop naturally. When the temperature of the catalyst section of the reaction tube drops below 20°C, inject a small amount of solvent polyethylene glycol 1000 into the reaction tube to wet the catalyst before stopping the reduction.

[0095] The reduced catalyst was transferred to a 100ml continuously stirred reactor under the protection of polyethylene glycol 1000. After closing the reactor cover and tightening the s...

Embodiment 2

[0100] Weigh 1.00g of Fischer-Tropsch synthesis industrial Fe-based catalyst (particle size 0.2-0.5mm), pour it into a quartz tube reactor with quartz wool sealed in the middle, seal the other end of the catalyst with quartz wool, and then put the reactor into In the resistance furnace, and connect the gas inlet and outlet pipelines. The reaction temperature is set to 230°C, and the space velocity is set to 3000h -1 , pressure 1atm, synthesis gas H 2 / CO is 2.0 to start reverting. After 20 hours of reduction, the temperature began to drop naturally. When the temperature of the catalyst section of the reaction tube drops below 20°C, inject a small amount of solvent tetraethylene glycol into the reaction tube to wet the catalyst before stopping the reduction.

[0101] The reduced catalyst was transferred to a 100ml continuous stirring reactor under the protection of tetraethylene glycol. After closing the reactor cover and tightening the screws, connect the inlet and outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com