Waste wool processing and recycling device for garment production

A technology of recycling and clothing, which is applied in the field of clothing production, can solve the problems of indistinguishable waste cashmere from high-quality cashmere, low percentage of successful recycling, and tilted stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

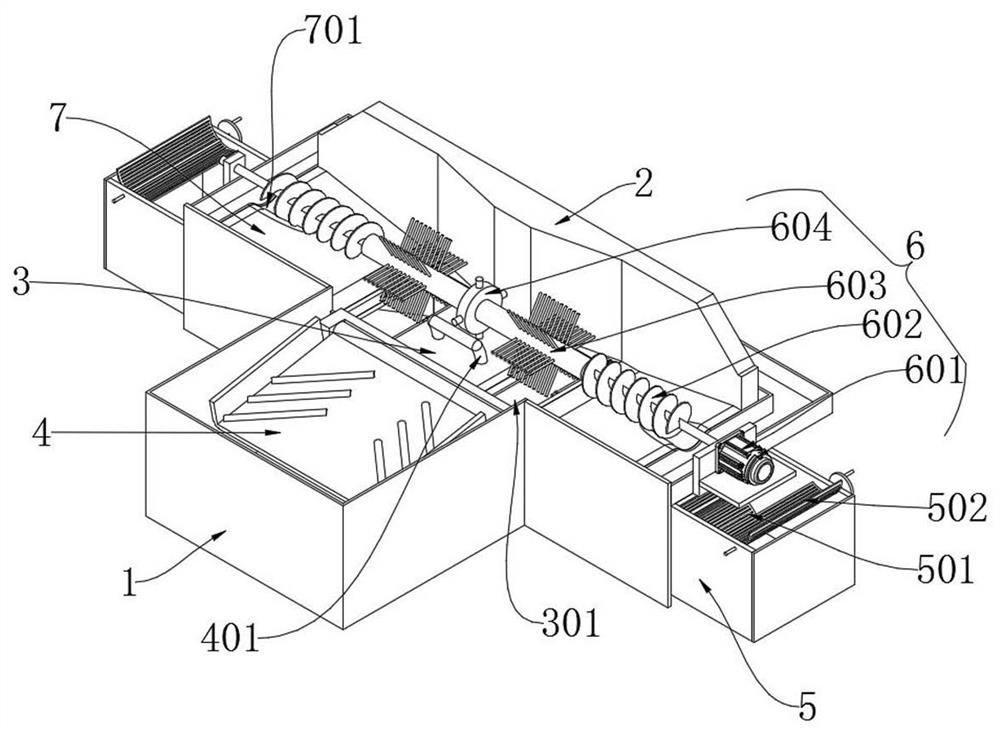

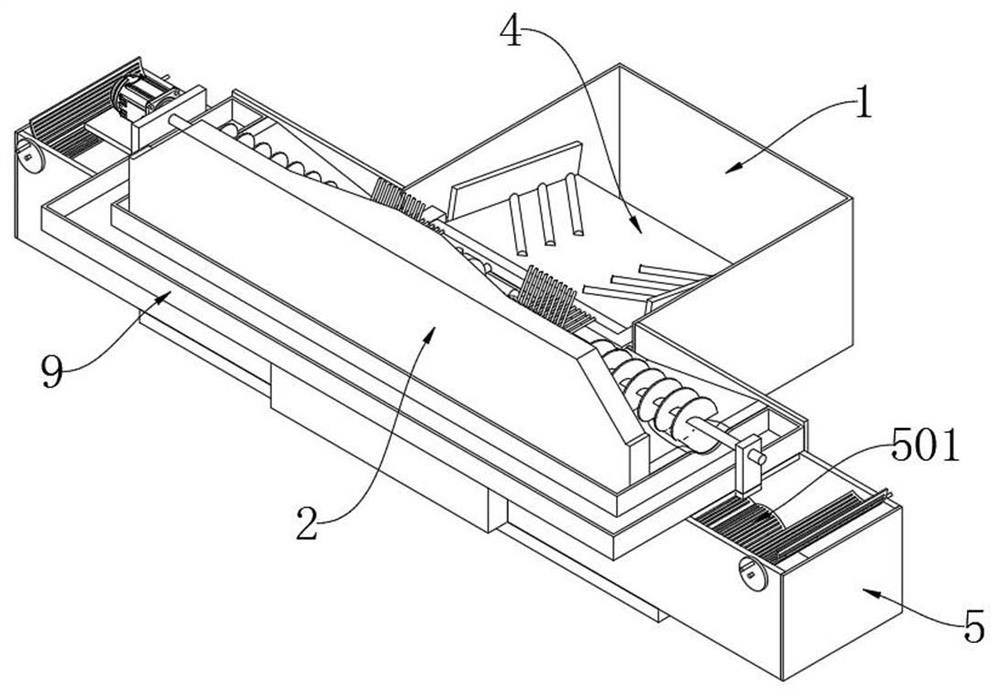

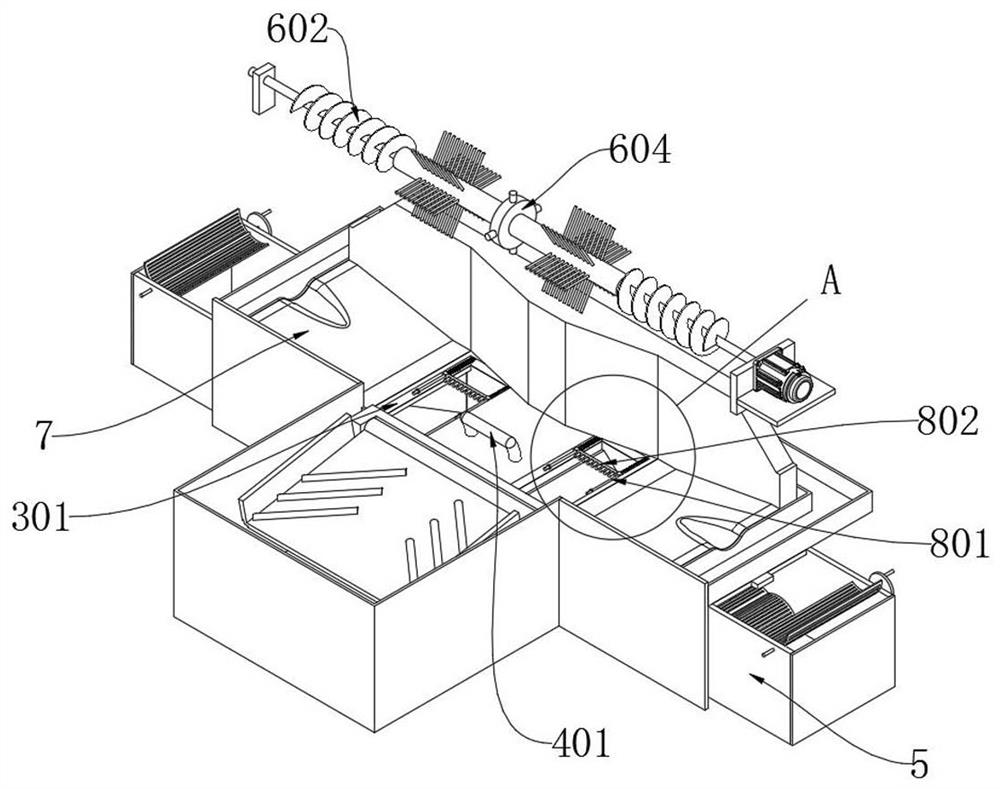

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The invention provides a waste cashmere processing and recovery treatment device for garment production, comprising a cashmere feeding box 1; the cashmere feeding box 1 is a T-shaped structure; The retaining wall 2 is fixedly installed horizontally and vertically upward; the left and right ends of the diversion box 3 are fixedly connected with the cleaning box 5 respectively; The top inner end of the cleaning box 5 is fixedly equipped with a separation ramp 7; the outer ends of the left and right two separation ramps 7 are fixedly connected with a U-shaped waste cashmere collection box 9; the upper middle of the left and right two separation ramps 7 Between horizontally fixedly installs the velvet feeding conveying mechanism 6; The left and right ends of the shunt box 3 vertically fixedly installs the rejecting mechanism 8 respectively.

[0035] Wherein, the cashmere box 1 includes a bottom box 101, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com