Composite material as well as preparation method and application thereof

A composite material and inner layer technology, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of single applicability of regeneration and recovery process, low specific surface area moisture content, and reduced harmful element content, etc. Avoid the effect of difficult separation, high specific surface area, and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

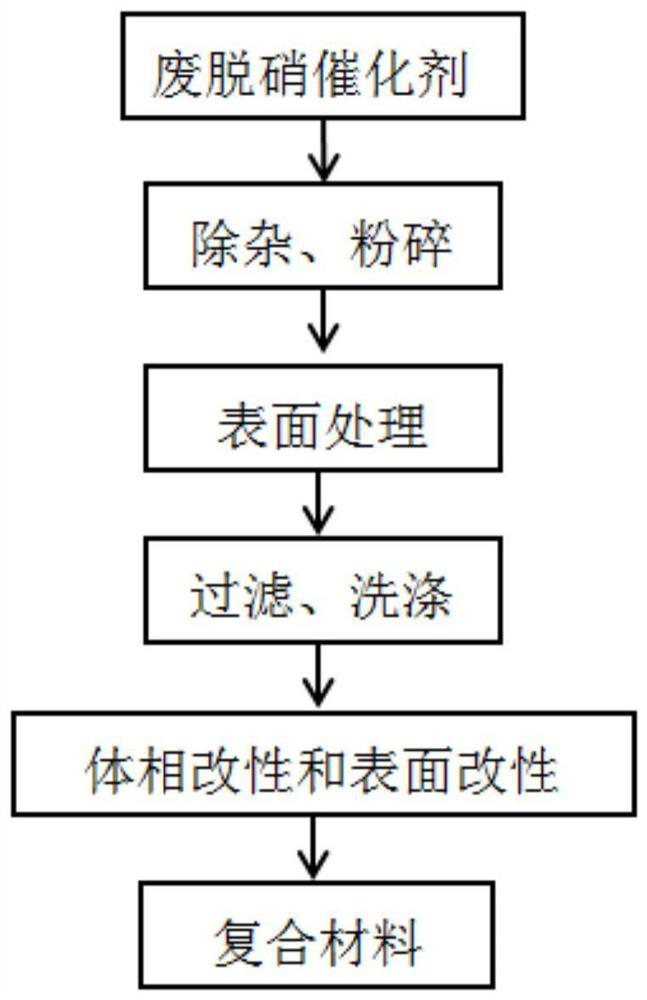

[0100] (1) Preparation of composite materials

[0101] a) 100 grams of waste denitrification catalyst was cleaned and soot blown under negative pressure, then ultrasonically cleaned and dried, then ball milled to 400 mesh, and then 600ml of NaOH solution with a mass fraction of 20wt% was added, treated at 180°C for 1 hour, and centrifuged. The solid-to-liquid ratio of spent denitration catalyst powder to surface treatment agent is 1:6g / mL.

[0102] b) Wash the filter residue in step a) three times with 200ml water respectively, then heat and stir 10wt% dilute sulfuric acid solution at 90°C for 30min, then wash with deionized water until the conductivity is 80μs / cm, and mix with water , beating to obtain a slurry, add 3wt% titanyl sulfate and 1wt% silane coupling agent to the above slurry, stir at room temperature for 1.5 hours, filter, then put the filter cake in an oven, and dry at 120°C After 24 hours, composite material A1 was obtained, with a moisture content of 8wt% and ...

Embodiment 2

[0104] (1) Preparation of composite materials

[0105] a) 100 grams of the waste denitration catalyst was cleaned, ultrasonically cleaned and dried, and then ball-milled to 400 mesh, then 200ml of NaOH solution with a mass fraction of 35wt% was added, reacted at 120°C for 4 hours, and then filtered to obtain a liquid phase and a solid phase, wherein , the solid-to-liquid ratio of the spent denitration catalyst powder to the surface treatment agent is 1:2g / mL.

[0106] b) The solid phase in step a) is first washed with deionized water until the conductivity is 69 μs / cm, then mixed with water and beaten to obtain a slurry, and 10 wt% is added to the above slurry Metatitanic acid and 1wt% silane coupling agent, stirred at 40°C for 1 hour, filtered to obtain a filter cake, then put the filter cake in an oven, and dried at 120°C for 24h to obtain composite material A2, containing water The ratio is 3.3wt%, and the specific surface area is 85m 2 / g, based on the total weight of th...

Embodiment 3

[0108] a) 100 grams of the waste denitration catalyst was cleaned, ultrasonically cleaned and dried, and ball-milled to 400 mesh, then 200ml of NaOH solution with a mass fraction of 25wt% was added, reacted at 135°C for 5 hours, and then filtered to obtain a liquid phase and a solid phase, wherein , the solid-to-liquid ratio of the spent denitrification catalyst powder to the surface treatment agent is 1:6g / mL, wherein the spent catalyst is a spent denitrification catalyst.

[0109] b) The solid phase in step a) is first washed with deionized water until the conductivity is 85 μs / cm, then mixed with water, beaten to obtain a slurry, and 6 wt% is added to the above slurry h 2 o 2 After 3 hours of treatment, add 6wt% titanium sulfate and stir at 50°C for 2 hours, filter to obtain a filter cake, and finally place the filter cake in an oven and dry at 120°C for 24 hours to obtain composite material A3. is 4.2wt%, and the specific surface area is 88m 2 / g, based on the total wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com