Method for improving the purity of methane in biogas produced by anaerobic digestion of sludge

An anaerobic digestion and biogas technology, which is applied in the field of environmental engineering, can solve the problems of low added value of biogas and low efficiency of biogas, and achieve the effects of enhancing destruction, improving acid hydrolysis, and improving methane purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

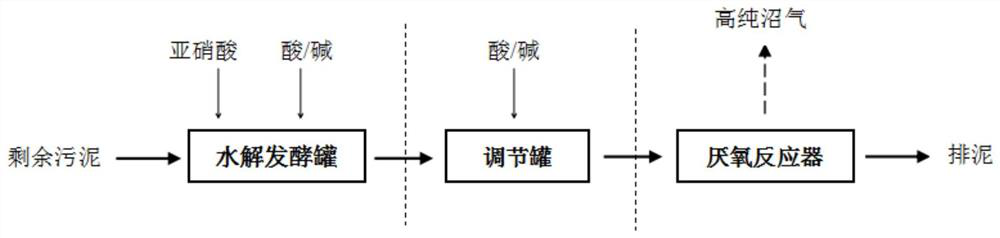

[0022] This example relates to a method for improving the purity of methane in biogas produced by anaerobic digestion of sludge. The process flow is as follows figure 1 As shown, it specifically includes the following steps:

[0023] A sewage plant in Shanghai, the object is the residual sludge of the secondary sedimentation tank, the solid content of the sludge after thickening is 20g / L. In the stage of hydrolytic acidification, the dosage of calcium nitrite is 500mg N / L (that is, 2.36g Ca(NO 2 ) 2 / L), while using 6M HCl solution to gradually adjust the pH of the fermentation mixture to 6.0, and the temperature was controlled at 37±2°C. Control the residence time of the sludge to 3 days, and keep the ORP in the hydrolysis fermentation tank at -100mV. After hydrolysis to produce acid, it is transported to the adjustment tank, and the pH is adjusted back to 6.5 with 5M NaOH solution, and then transported to the anaerobic reactor. The abundance of hydrogenotrophic methanogen...

Embodiment 2

[0025] This embodiment relates to a method for improving the purity of methane in biogas produced by anaerobic digestion of sludge, which specifically includes the following steps:

[0026] For a domestic sewage plant in Shanghai, the object is the residual sludge in the secondary sedimentation tank, and the solid content of the sludge after thickening is 40g / L. The dosage of calcium nitrite is 2000mg N / L (that is, 9.43g Ca(NO 2 ) 2 / L), use 6M HCl solution to gradually adjust the pH of the fermentation mixture to 4.0, control the temperature at 37±2°C, and mix well. The sludge residence time in the hydrolysis fermentation tank is 1d, and the ORP in the hydrolysis fermentation tank is kept at -200mV. After hydrolysis to produce acid, it is transported to the adjustment tank, and the pH is adjusted back to 6.3 with 5M NaOH solution, and then transported to the anaerobic reactor. The abundance of hydrogenotrophic methanogen Methanobacterium reaches 40%. The sludge residence t...

Embodiment 3

[0028] This embodiment relates to a method for improving the purity of methane in biogas produced by anaerobic digestion of sludge, which specifically includes the following steps:

[0029] In a sewage plant in Shanghai, the object is to discharge sludge from the thickening tank. The solid content of the sludge is 30g / L, and the dosage of calcium nitrite is 1300mg N / L (ie, 6.13g Ca(NO 2 ) 2 / L), using 6M HCl solution to gradually adjust the pH of the fermentation mixture to 5.0, the temperature was controlled at 37±2°C, and the mixture was evenly mixed with continuous stirring. The sludge residence time in the hydrolysis fermentation tank is 2 days, and the ORP in the hydrolysis fermentation tank is kept at -300mV. After hydrolysis to produce acid, it is transported to the adjustment tank, and the pH is adjusted back to 6.0 with 5M NaOH solution, and then transported to the anaerobic reactor, where the abundance of hydrogenotrophic methanogen Methanobacterium reaches 50%. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com