A block anaerobic treatment method for organic wastewater

A technology for anaerobic treatment and organic wastewater, applied in the field of water treatment, can solve the problems of low treatment efficiency, imprecise process control, difficulty in the proliferation of granular sludge, etc., and achieve the effect of reducing consumption, improving reaction efficiency and reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

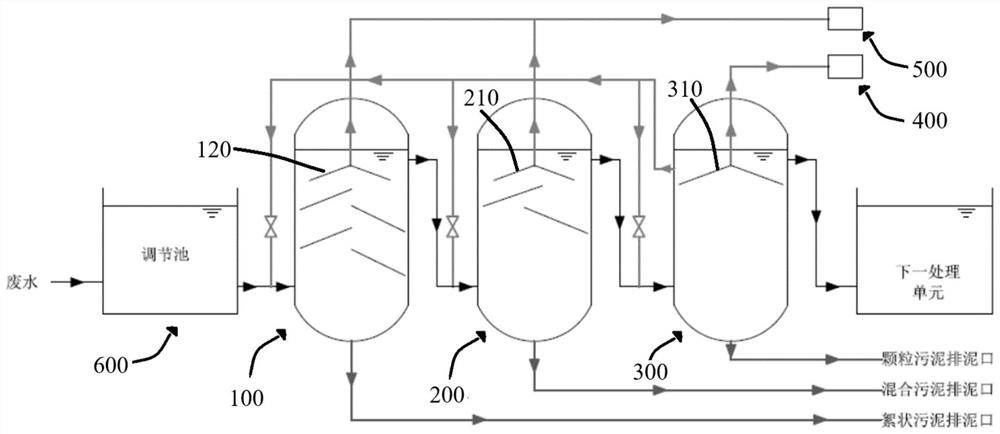

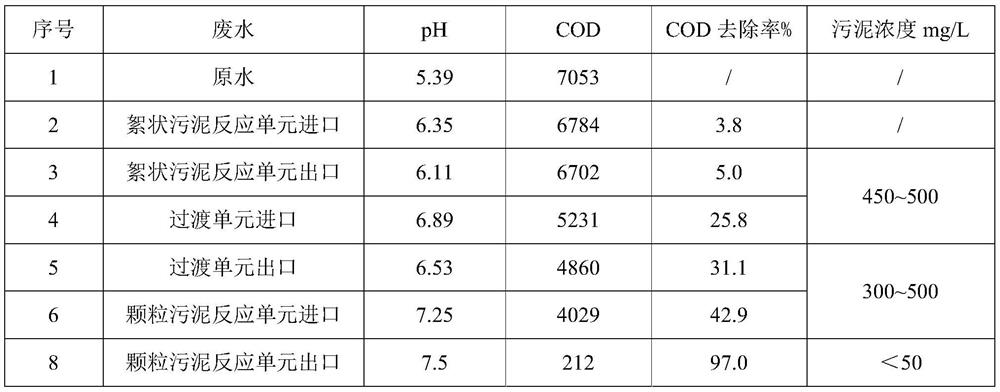

[0053] The diameter of the flocculent sludge treatment unit 100 in this embodiment is 3.5m, and the total effective height is 1.5m. Four sludge baffles are arranged in the flocculent sludge treatment unit 100, and the baffles and the side walls of the reactor adopt The bracket is connected to prevent the sludge dead zone. The total length of the bracket and the sludge baffle is 1.5m, and a sludge baffle is arranged symmetrically every 0.3m. The angle between the baffle and the side wall of the reactor is 70 degrees The diameter of the transition unit 200 is 3.5m, and the total effective height is 4m. Two sludge baffles are arranged in the transition unit 200, and the baffles and the reactor side walls are connected by brackets to prevent sludge dead zones. The total length of the sludge baffle is 1.0m, and the left and right baffles are symmetrically arranged at a height of 2.5m in the transition unit. The angle between the baffle and the side wall of the reactor is 65 degrees,...

Embodiment 2

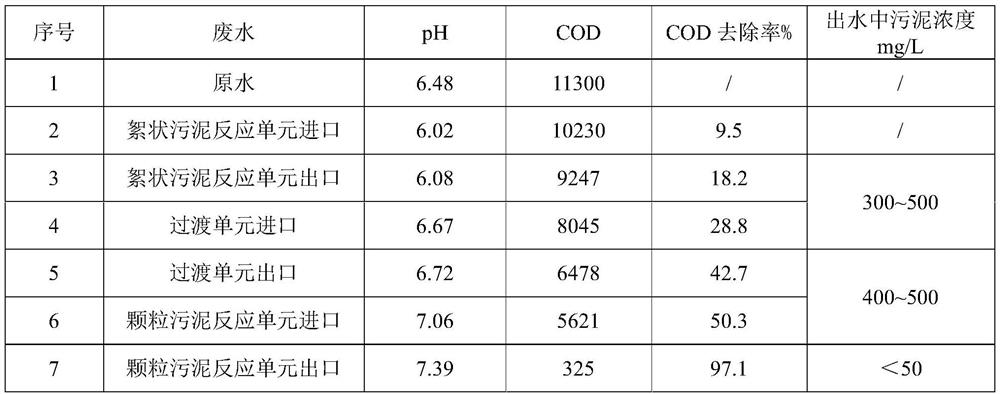

[0069] The diameter of the flocculent sludge treatment unit 100 described in this embodiment is 4.8m, and the total effective height is 2.0m. Four sludge baffles are arranged in the reactor of the flocculent sludge treatment unit 100, and the baffles and the reactor The side walls are connected by brackets to prevent sludge dead zones. The total length of the brackets and sludge baffles is 1.8m, and a sludge baffle is arranged symmetrically every 0.4m. The angle between the baffles and the side wall of the reactor The diameter of the transition unit 200 is 4.0m, and the total effective height is 4m. There are 4 sludge baffles in the transition unit 200, and the baffles are connected to the side wall of the reactor by brackets to prevent sludge dead zone , the total length of the bracket and the sludge baffle is 1.5m, and the baffles are symmetrically arranged at the transition unit heights of 2.0m and 3.0m, and the angle between the baffle and the side wall of the reactor is 65...

Embodiment 3

[0085] The device in this embodiment is a tower structure, and the flocculent sludge treatment unit 100, the transition unit 200, and the granular sludge unit 300 are integrated into a reaction tower, and the diameter of the reaction tower is 3.5m. The total effective height of the flocculent sludge treatment unit 100 in this embodiment is 2.0m, and two sludge baffles are arranged inside, and the baffles are connected to the side wall of the reactor by brackets to prevent sludge dead zones. The total length with the sludge baffle is 0.8m, and a sludge baffle is arranged symmetrically at an effective height of 1.5m. The angle between the baffle and the side wall of the reactor is 60 degrees. In the flocculent sludge treatment unit 100 100 two-phase separators 120 are arranged on the inner top, and a partition with holes is arranged between the flocculent sludge treatment unit 100 and the transition unit 200, and through holes of 0.3 to 0.5 mm are arranged on the partition; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com