Method for anaerobic fermentation of livestock and poultry manure

A technology of livestock manure and anaerobic fermentation, applied in chemical instruments and methods, animal husbandry wastewater treatment, biological sludge treatment, etc., can solve problems such as high energy consumption and low efficiency, reduce operating costs, improve efficiency, promote Effects of anaerobic digestion of livestock manure for methane production potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

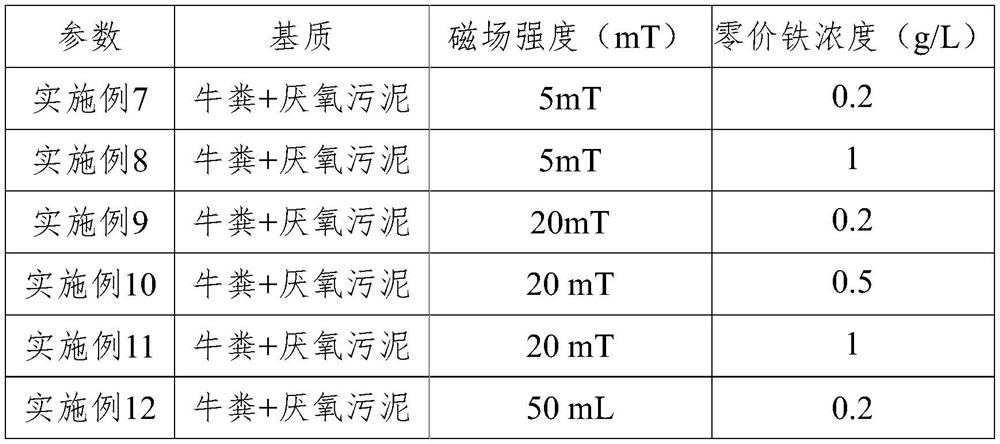

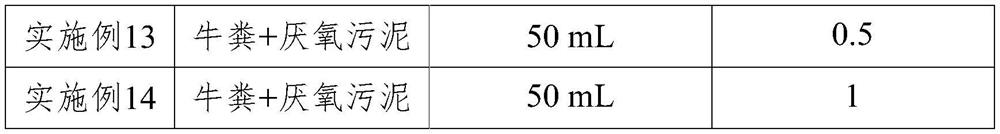

Examples

Embodiment 1~6

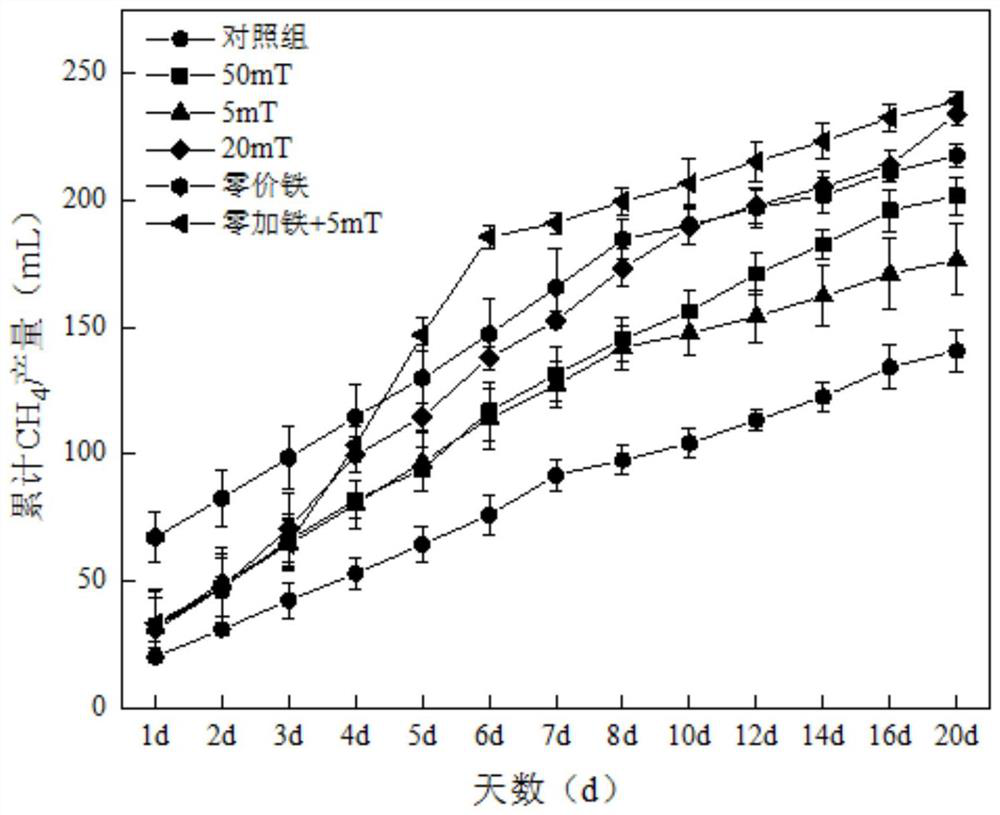

[0046] S1. Before inoculation of anaerobic sludge, anaerobic culture was carried out with livestock and poultry manure for 14 days, and 43 g of cow manure was mixed with 120 g of anaerobic sludge to obtain fermentation raw materials. Nitrogen blowing and dragging for 2 minutes to maintain a strict anaerobic environment in the reaction flask;

[0047] S2. Place the anaerobic reaction flask in a water bath for anaerobic fermentation, shake it manually 3 times in the morning and noon every day to make the fermentation liquid evenly mixed, and set the reaction temperature to 37°C during the entire experiment, and recover methane at the same time.

Embodiment 2~4

[0049]S1. Before inoculation of anaerobic sludge, anaerobic culture was carried out with livestock and poultry manure for 14 days, and 43 g of cow manure was mixed with 120 g of anaerobic sludge to obtain fermentation raw materials. Nitrogen was blown for 2 minutes to maintain a strict anaerobic environment in the reaction flask;

[0050] S2. Apply a magnetic field of 5mT, 20mT, and 50mT outside the anaerobic bottle respectively;

[0051] S3. Place the anaerobic reaction flask in a water bath for anaerobic fermentation, shake it manually 3 times in the morning and noon every day to make the fermentation liquid mix evenly, and set the reaction temperature to 37°C during the entire experiment, and recover methane at the same time.

Embodiment 5

[0053] S1, 43g of cow dung is mixed with 120g of anaerobic sludge to obtain fermentation raw materials, and the remaining part is added to 150mL with water, and is loaded into an anaerobic reaction flask; with nitrogen blowing for 2min to maintain a strict anaerobic environment in the reaction flask;

[0054] S2. Add zero iron 0.5g / L to the anaerobic reaction bottle;

[0055] S3. Place the anaerobic reaction flask in a water bath for anaerobic fermentation, shake it manually 3 times in the morning and noon every day to make the fermentation liquid mix evenly, and set the reaction temperature to 37°C during the entire experiment, and recover methane at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com