Method for producing methane from high-concentration phenol-containing wastewater

A high-concentration technology for phenol wastewater, applied in the field of methane production from high-concentration phenol-containing wastewater, can solve problems such as human environmental impact, human and microbial toxicity, and achieve the effects of optimizing transformation pathways, promoting electron transfer, and promoting methane production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

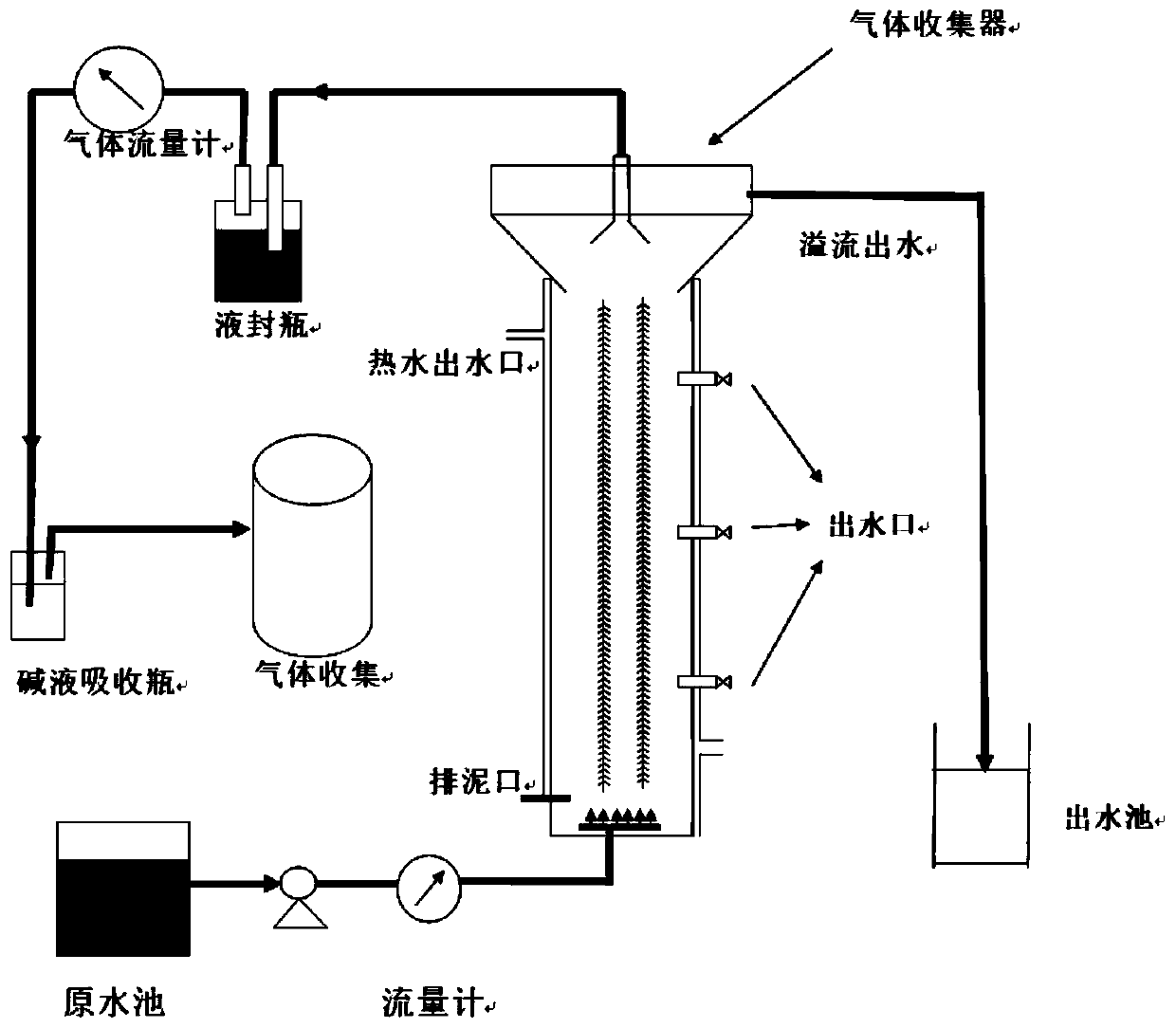

[0024] see figure 1 , take the mixed solution (GW+CGW, volume ratio 1:1) of high-concentration phenol-containing wastewater and glucose solution (COD=2000mg / L) as the influent water sample, enter from the bottom of the AF reactor, and pass the AF anaerobic reaction At the same time, the concentration of graphene added to the reactor is 10g / L, and the HRT of the system is maintained for 48 hours. The waste water is filtered through the filter membrane in the AF reactor, and the co-metabolism of the glucose substrate and the adsorption of graphene and the promotion of anaerobic Oxygen microbial electron transfer function, the treated wastewater finally flows out from the top. The generated methane gas is collected after passing through the liquid-sealed bottle and the lye absorption bottle.

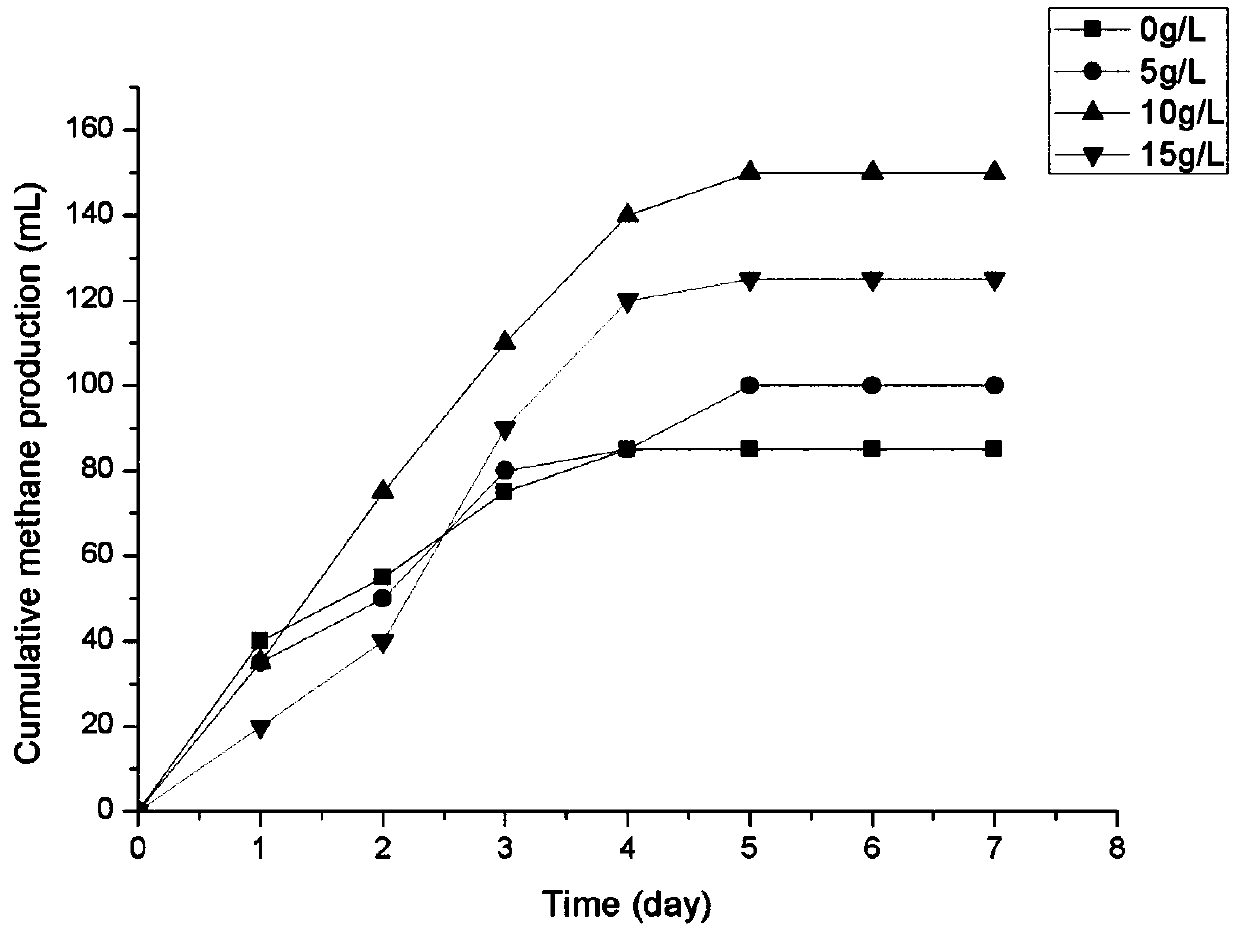

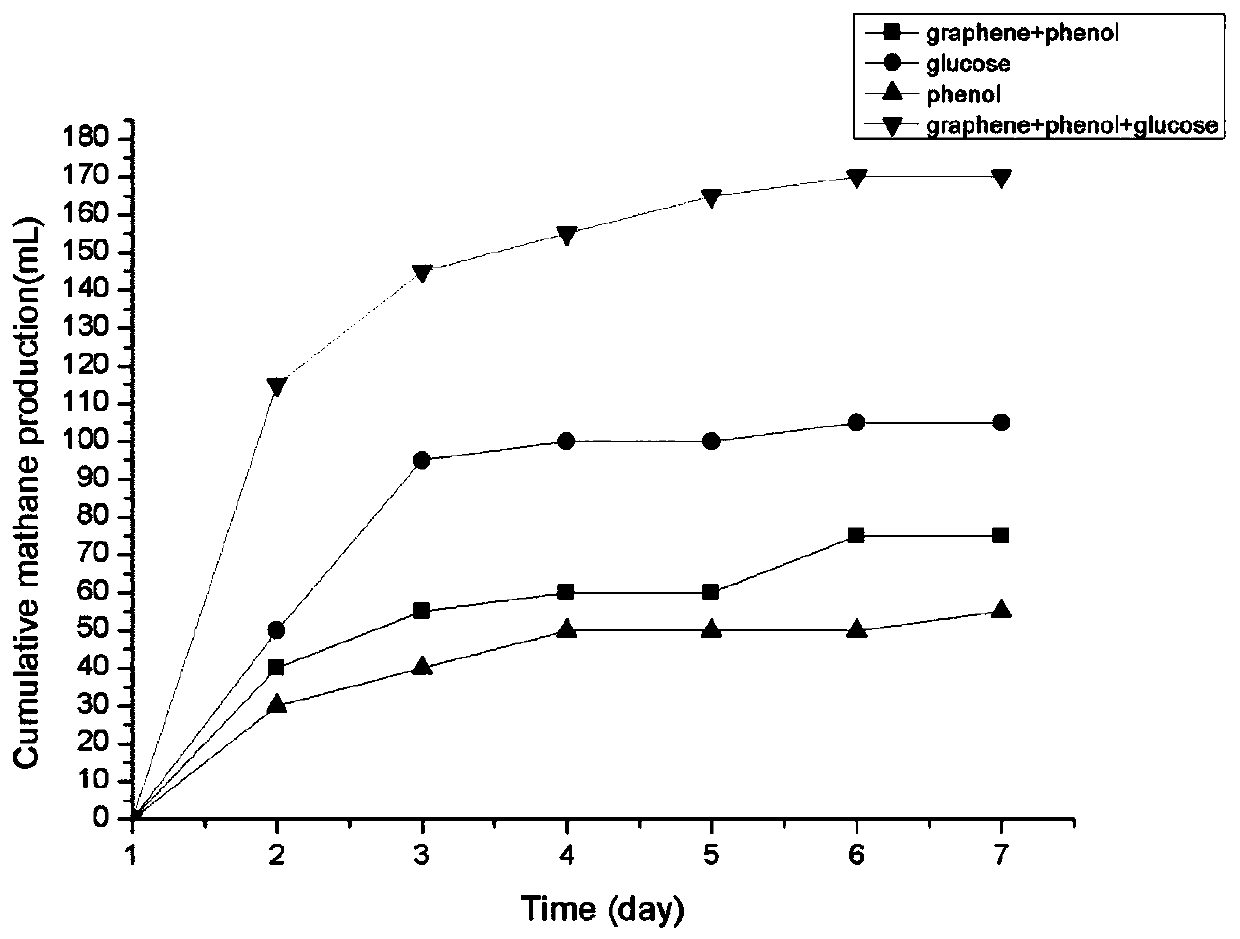

[0025] 1. Small test of accumulative methane production by adding graphene to phenolic wastewater

[0026] Take 4 380mL serum bottles and inoculate a certain amount of anaerobic sludge an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com