Device and method for biosynthesizing methane based on carbon emission reduction CO2

A biosynthesis and carbon emission reduction technology, applied in enzymology/microbiology devices, methods of stress-stimulating microbial growth, biosynthesis, etc., can solve the problems of carbon emission reduction and energy recycling, etc. Recycling efficiency, simple replacement, and the effect of enhancing methane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

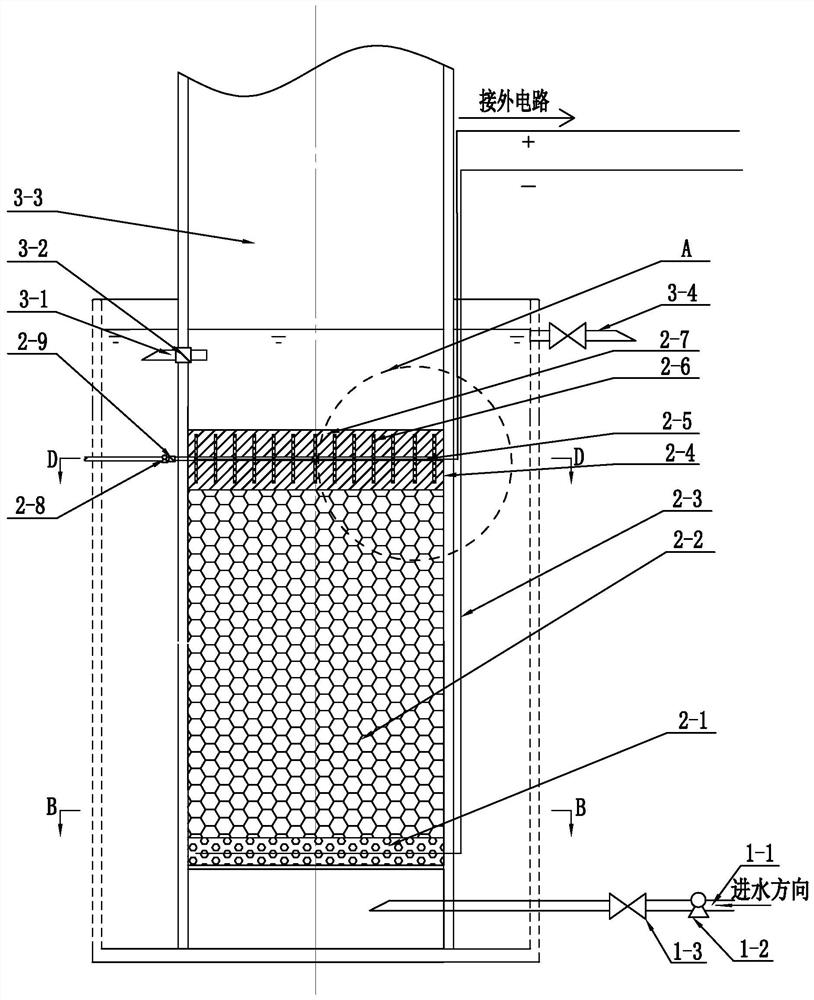

[0032] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of specific embodiment one, the height of the one-way drain pipe 3-1 is lower than the height of the treated water drain pipe 3-4 (to avoid methane gas from the one-way drain pipe 3 -1 leaks out and all the gas enters the methane collection device).

specific Embodiment approach 3

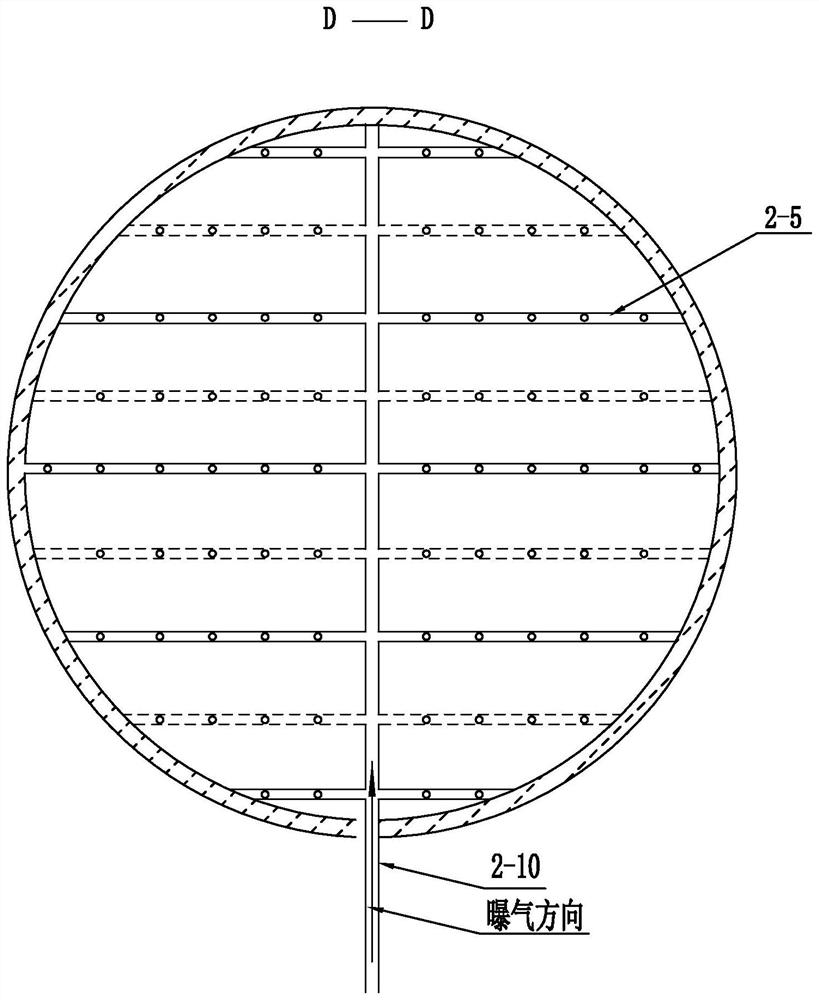

[0033] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of specific embodiment 1. The biocathode 2-4 includes a plurality of nickel tube electrodes 2-5, a plurality of aeration hole tubes 2-6 and graphite felt 2-7; The plurality of nickel tube electrodes 2-5 are horizontally arranged and connected to form a nickel tube electrode tube plate, and a plurality of aeration hole tubes 2-6 are arranged in an array on the nickel tube electrode tube plate, and the plurality of aeration holes The tubes 2-6 are all nickel tubes, and a plurality of aeration hole tubes 2-6 are connected with the nickel tube electrodes 2-5, and the upper side of the plurality of aeration hole tubes 2-6 extends upwards, and the lower side extends downwards. A nickel tube electrode 2-5 and a plurality of aeration hole tubes 2-6 are combined to form a nickel tube electrode body, and the surface of the nickel tube electrode body is modified with ZnO and Fe 3 o ...

specific Embodiment approach 5

[0036] Specific implementation mode five: as figure 1 As shown, this embodiment is a further description of the third embodiment, and the multiple aeration holes of the aeration hole tube 2-6 are arranged in a staggered manner.

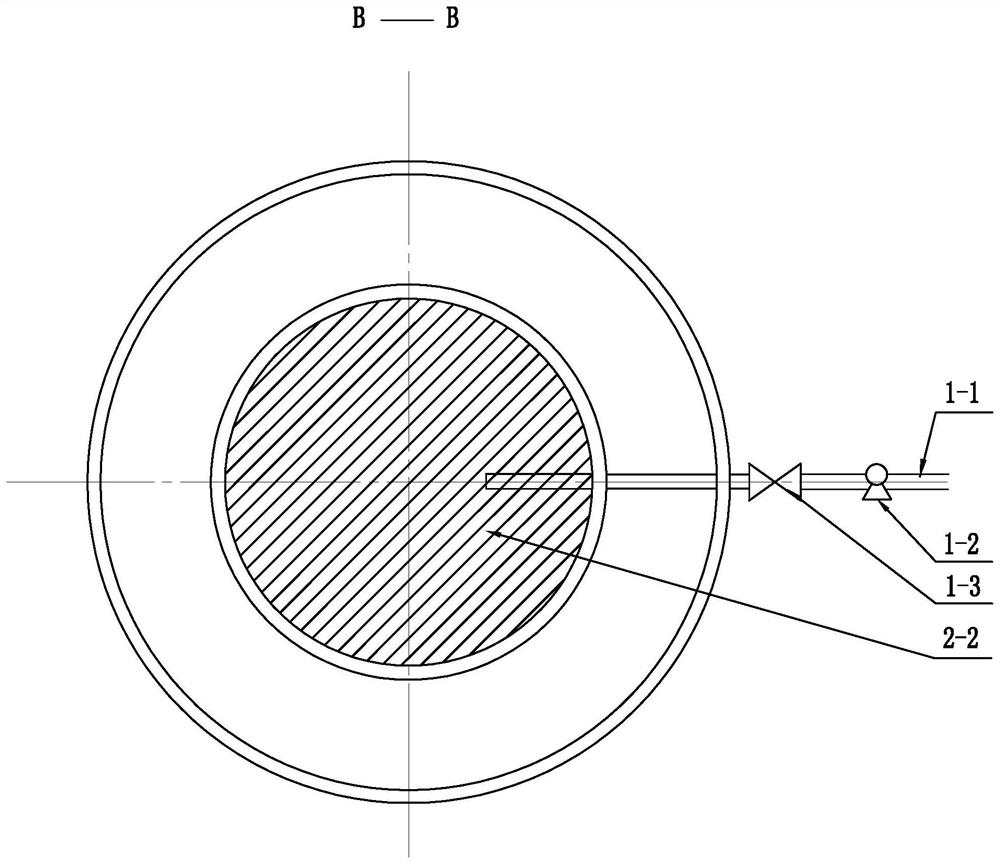

[0037] Specific implementation mode six: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The bioanode 2-1 is made of a modular porous filler with electrical conductivity (in addition to providing or absorbing electrons as an electrode, the porous filler also provides a large specific surface area for microorganisms to adhere to film), and the thickness of the bioanode 2-1 is 0.1m (materials include but not limited to graphene airgel, carbon sponge, foam copper, etc. Taking graphene as an example, its parameters are as follows: The specific surface area is 400-1000m 2 / g, the specific capacitance is 144F / g, the impedance is 0.65Ohm, and the graphene resistivity is 0.001Ω·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com