A rapid production method of greening special base material

A production method and base material technology, applied in the biological field, can solve the problems of heavy metal pollution, physical and chemical properties, affecting the growth of garden plants, and lack of nutrition, etc., and achieve the effects of reducing the infectivity of organic bacteria, accelerating fermentation preparation, and accelerating decomposition and maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

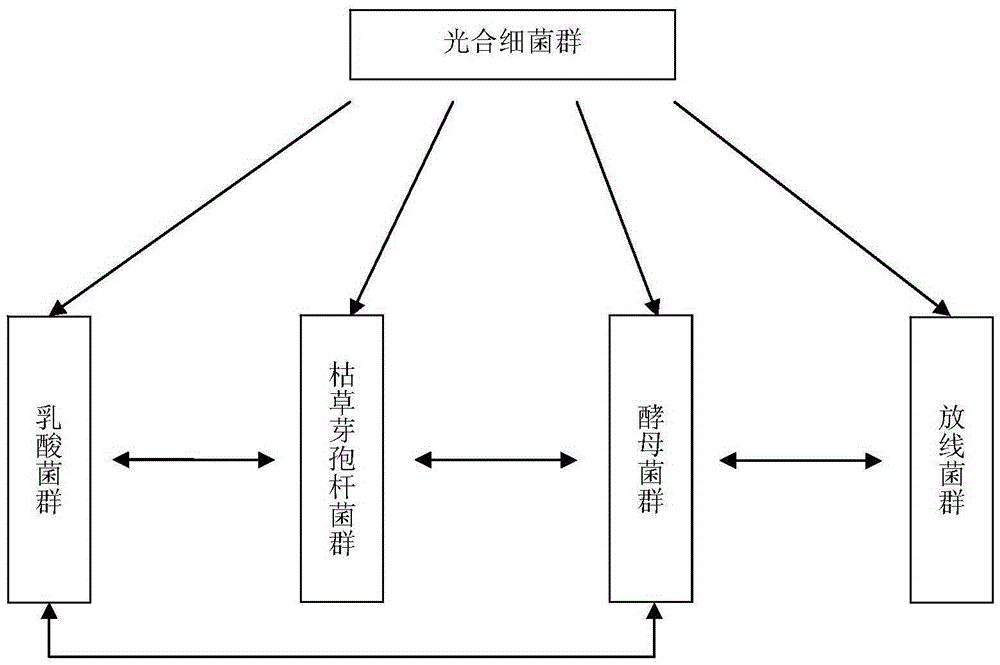

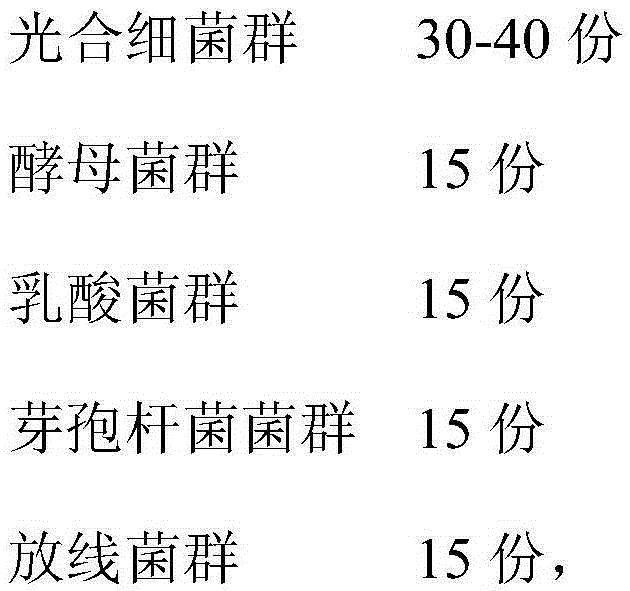

[0043] Take the following components by weight as the composite bacterial liquid:

[0044]

[0045] The number of bacteria in each bacterial group is not less than 10 9 pcs / mL

[0046] Dissolve sucrose (tablet sugar) into sucrose water with warm water at 40°C first, put the sucrose water into a clean bucket after cooling, stir well, put the compound bacteria solution into the bucket after standing for 1 day (clear water: sucrose: compound bacteria solution The mass ratio is 2:2:1), fully stirred, covered and sealed, and cultured at 25°C for 25 days in a cool and clean environment to form a microbial fermentation liquid; use a sprayer to evenly spray the microbial fermentation liquid on the surface of the garden litter to be fermented , and covered with a plastic film, and fermented for 30 days to obtain the base material.

Embodiment 2

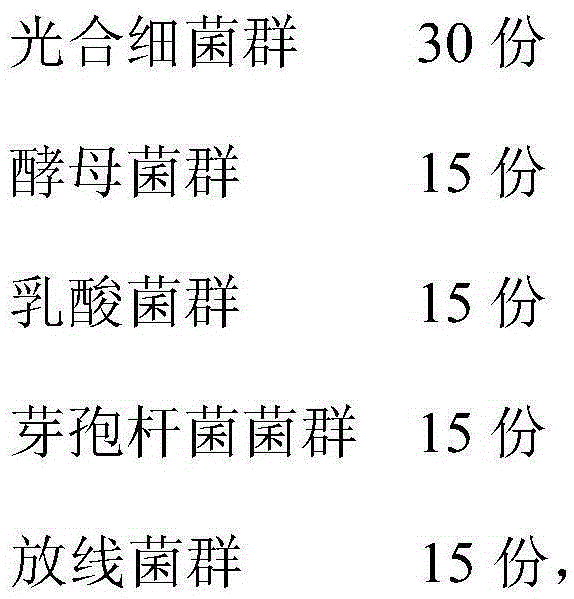

[0048] The following weight ratio components are used as the compound bacterial liquid:

[0049]

[0050] The number of bacteria in each bacterial group is not less than 10 9 pcs / mL

[0051] Dissolve sucrose (tablet sugar) into sucrose water with warm water at 38°C first, put the sucrose water into a clean bucket after cooling, stir well, put the compound bacteria solution into the bucket after standing for 2 days (clean water: sucrose: compound bacteria solution The mass ratio is 2:2:1), fully stirred, covered and sealed, and cultured at 25°C for 26 days in a cool and clean environment to form a microbial fermentation liquid; spray the microbial fermentation liquid evenly on the surface of the sludge to be fermented with a sprayer, and use Cover with a plastic film and ferment for 25 days to obtain the base material.

Embodiment 3

[0053] The following weight ratio components are used as the compound bacterial liquid:

[0054]

[0055] The number of bacteria in each bacterial group is not less than 10 9 pcs / mL

[0056]Dissolve sucrose (tablet sugar) into sucrose water with warm water at 42°C first, put the sucrose water into a clean bucket after cooling, stir well, put the compound bacteria solution into the bucket after standing for 1 day (clean water: sucrose: compound bacteria solution The mass ratio is 4:2:1), fully stirred, covered and sealed, and cultured at 25°C for 30 days in a cool and clean environment to form a microbial fermentation liquid; use a sprayer to evenly spray the microbial fermentation liquid on the surface of poultry manure to be fermented, Cover with a plastic film and ferment for 25 days to obtain the base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com