A control method for crystallization and phosphorus removal of dairy waste water

A technology for removing phosphorus from dairy wastewater and crystallization, which is used in water treatment parameter control, food industry wastewater treatment, chemical instruments and methods, etc., can solve the problems of large fluctuations in COD concentration and pH value, and achieve sustainable recycling , the effect of reducing phosphorus load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

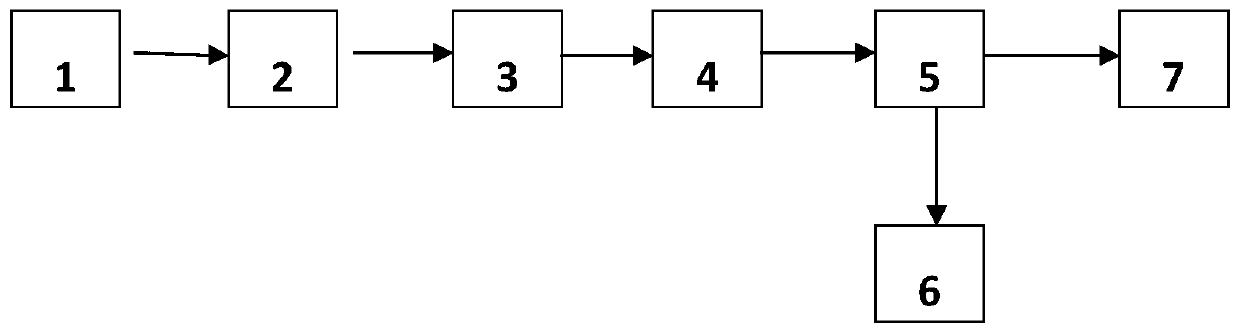

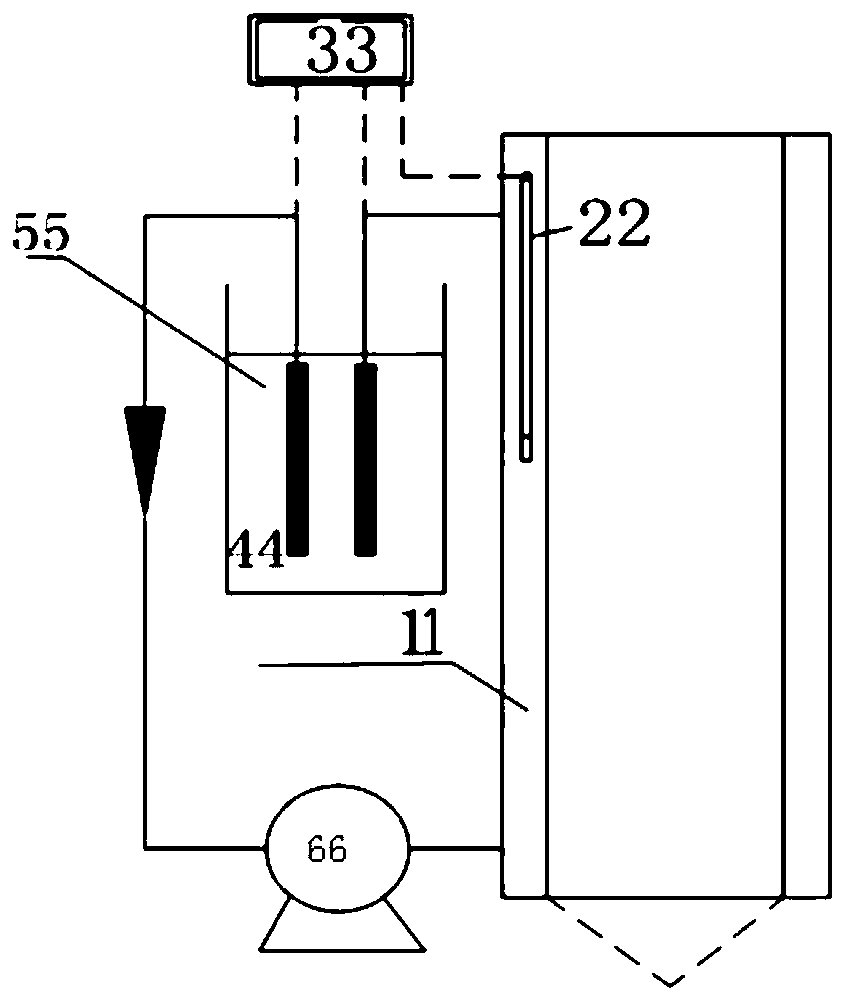

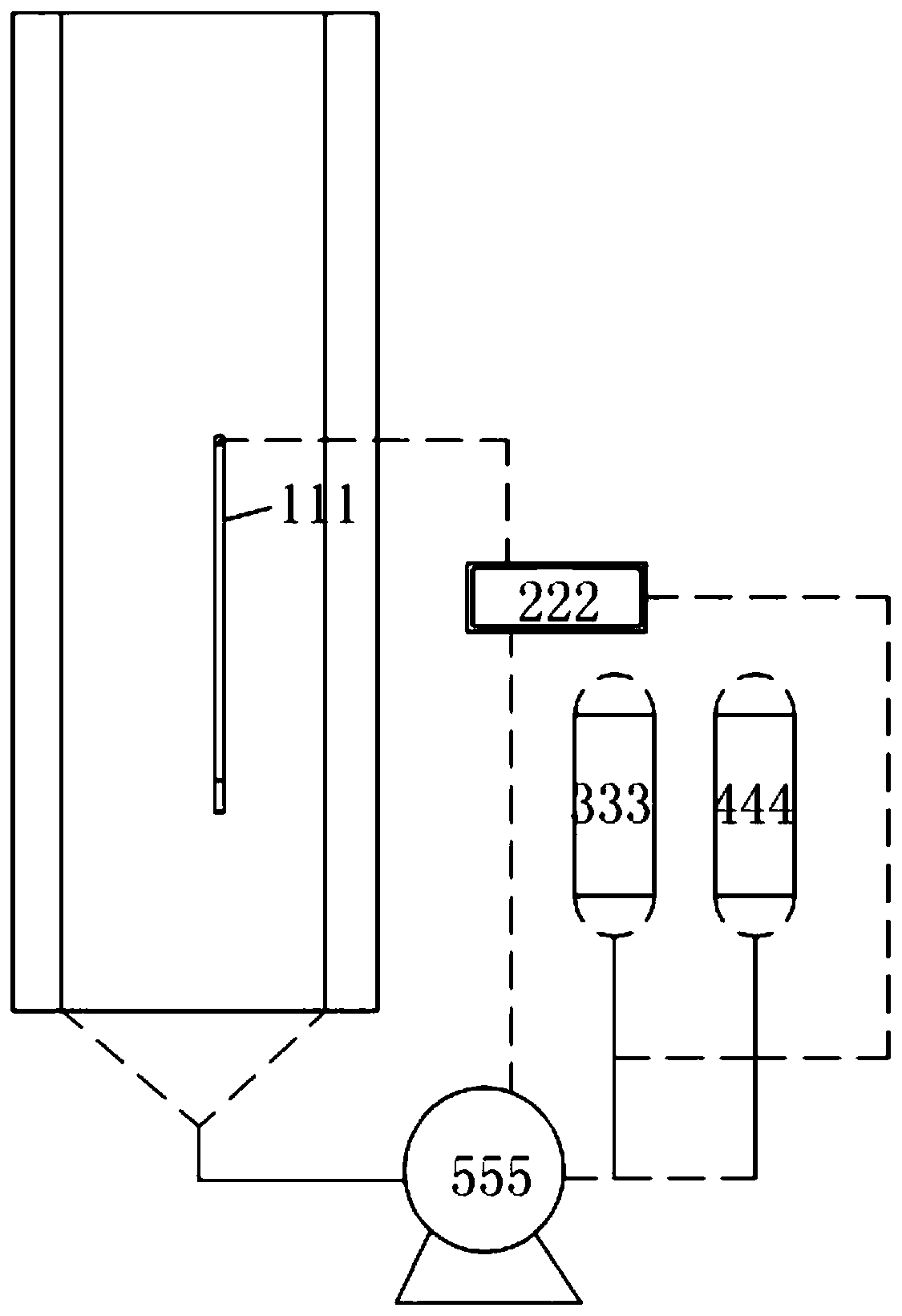

[0031] Step 1 Take the wastewater (raw water) before the anaerobic tank in the dairy wastewater treatment process; Step 2 Raw water is filtered through a 3-5mm fine grid impurity; Step 3 Then add bone carbon to the filtered dairy wastewater, throw Dosing ratio n(Ca):n(P)=3.0:1, stirring intensity 180r / min, stirring time 60min, pH during the reaction is 7.8, temperature is 25°C; after the reaction in step 4, let stand for 1h, Separate the supernatant; filter through a 0.45 μm microporous membrane in step 5; discharge the filtrate in step 6; place the crystalline precipitated product in step 7 to dry in an oven at 35° C. for 48 hours, and recover the crystalline precipitate. The composition of the composite crystal nucleus agent is composed of bone carbon, tobermorite and diatomaceous earth in a mass ratio of 3:2:1.

Embodiment 2

[0033] Step 1 Take the wastewater (raw water) before the anaerobic tank in the dairy wastewater treatment process; Step 2 Raw water is filtered through a 3-5mm fine grid impurity; Step 3 Then add bone carbon to the filtered dairy wastewater, throw Dosing ratio n(Ca):n(P)=3.3:1, stirring intensity 200r / min, stirring time 60min, adjust the pH value during the reverse process to 8.3, and control the temperature at 26°C; Set aside for 1 hour to separate the supernatant; filter through a 0.45 μm microporous membrane in step 5; discharge the filtrate in step 6; place the crystalline precipitated product in step 7 in an oven at 38° C. for 48 hours to recover the crystalline precipitate. The composition of the composite crystal nucleus agent is composed of bone carbon, tobermorite and diatomaceous earth in a mass ratio of 3:2:1.

Embodiment 3

[0035] Step 1 Take the wastewater (raw water) before the anaerobic tank in the dairy wastewater treatment process; Step 2 Raw water is filtered through a 3-5mm fine grid impurity; Step 3 Then add bone carbon to the filtered dairy wastewater, throw Dosing ratio n(Ca):n(P)=3.5:1, stirring intensity 210r / min, stirring time 60min, adjust the pH value during the reverse process to 8.8, and control the temperature at 28°C; Set aside for 1.5 hours, and separate the supernatant; step 5, filter through a 0.45 μm microporous membrane; step 6, discharge the filtrate; step 7, place the crystalline precipitated product in an oven at 40° C. to dry for 50 hours, and recover the crystalline precipitate. The composition of the composite crystal nucleus agent is composed of bone carbon, tobermorite and diatomaceous earth in a mass ratio of 3:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com