Reaction system suitable for organic solid waste resource utilization

A reaction system and organic solid technology, applied in the direction of gas production bioreactor, bioreactor/fermenter for specific purposes, bioreactor/fermenter combination, etc., can solve the problem of low fermentation efficiency and gas production efficiency, biogas residue Difficult to deal with, easy "acidification" and other problems, to achieve the effect of convenient operation, reducing the amount of biogas residue, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

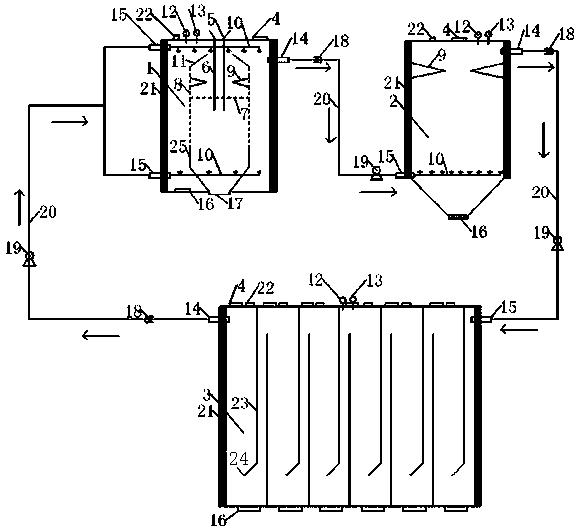

[0017] A reaction system suitable for resource utilization of organic solid waste according to the present invention will be described in detail below with reference to the accompanying drawings.

[0018] like figure 1 , a reaction system suitable for resource utilization of organic solid waste, including a high-temperature hydrolysis fermentation reaction device 1, a medium-temperature acidification fermentation reaction device 2 and a methane fermentation reaction device 3; wherein, the high-temperature hydrolysis fermentation reaction device 1 includes a tank body, The outer wall of the tank is provided with an insulating layer, and a heating device 21 is arranged between the outer wall of the tank and the insulating layer; the top wall of the tank body is provided with a feeding port 5, and a feeding pipe 6 is arranged below the feeding port 5, and the feeding The upper end of the pipe 6 is fixedly connected with the top wall of the tank body; the top wall of the tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com