Method for improving efficiency of blue-green algae or straw anaerobic methane production process

A technology of straw and cyanobacteria, applied in waste fuel, fermentation, etc., can solve the problems of low methane production and slow methane generation rate, and achieve the effects of increasing methane production, stable reaction process and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

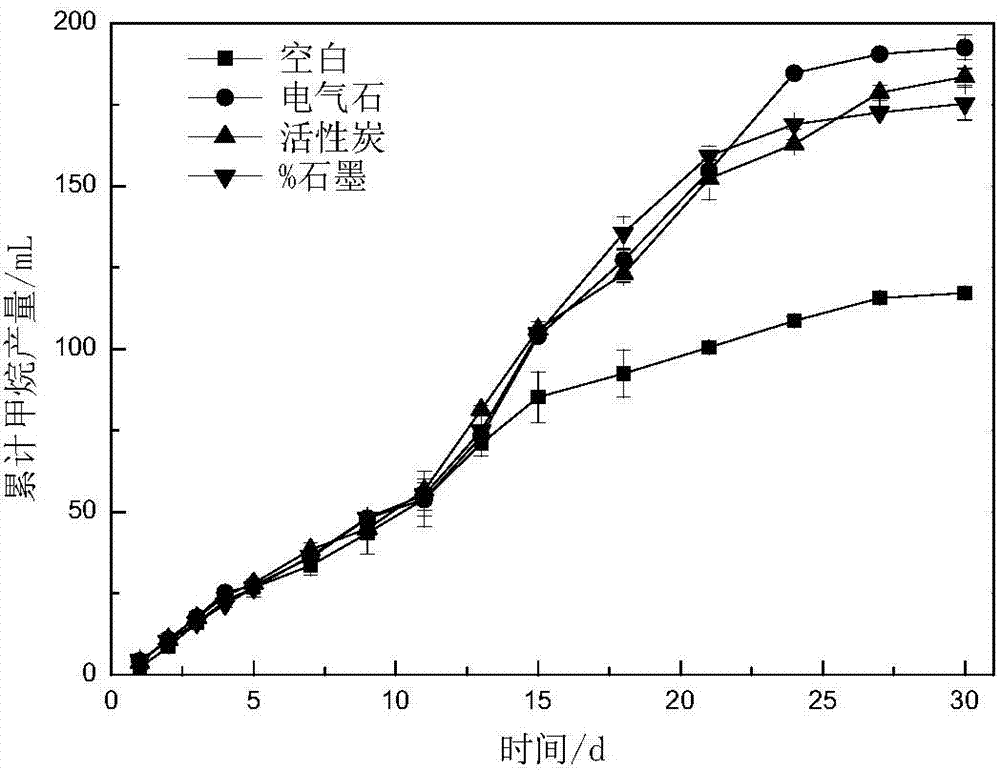

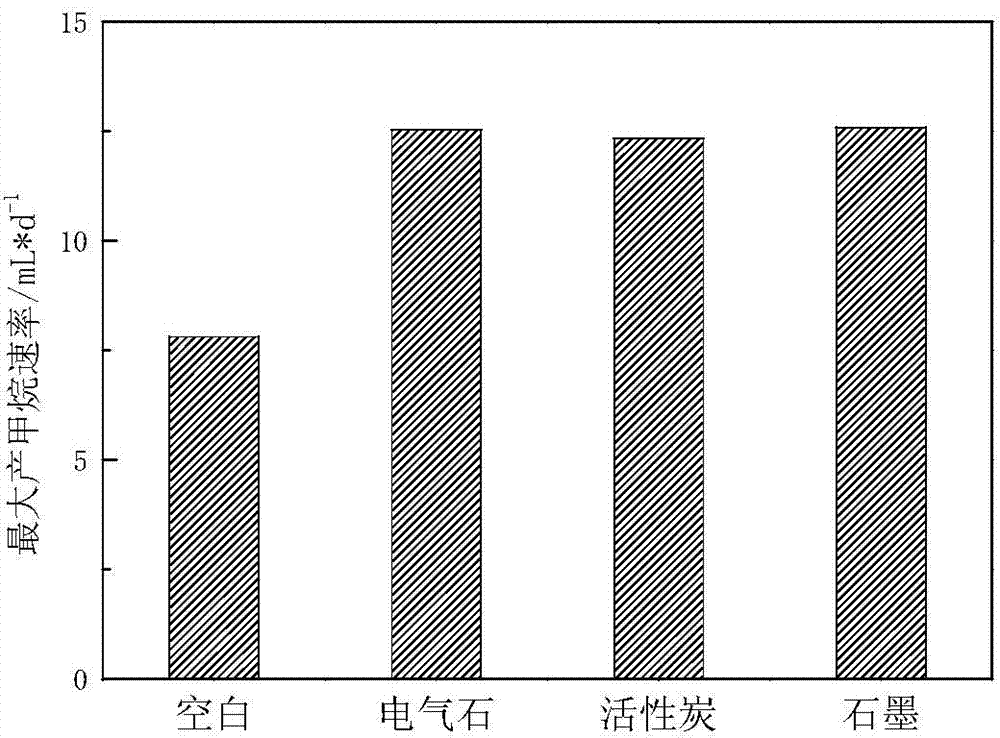

Embodiment 1

[0024] Take 4 groups of 250mL serum bottles as cyanobacteria anaerobic reactors, 4 in each group, and the actual reaction volume is 200mL. Add cyanobacteria, anaerobic inoculation sludge, buffer salt, trace element aqueous solution and vitamin aqueous solution to the serum bottles to make the serum The initial concentration of cyanobacteria in the bottle is 5g VS / L, the initial concentration of anaerobic inoculated sludge is 2g VS / L, the addition amount of buffer salt, trace element aqueous solution and vitamin aqueous solution is all 1mL / L, then through 1mol / L HCl and 1mol / L NaOH solution to adjust the pH of the system to 7;

[0025] The concentration of various substances in the buffer salt is: NH 4 Cl 10mmol / L, KH 2 PO 4 1mmol / L, MgCl 2 0.5mmol / L, CaCl 2 0.5mmol / L, NaHCO 3 5mmol / L, 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (Hepes) 10mmol / L.

[0026] The concentration of various substances in the trace element aqueous solution is: FeCl 2 10mmol / L, CoCl 2 1mm...

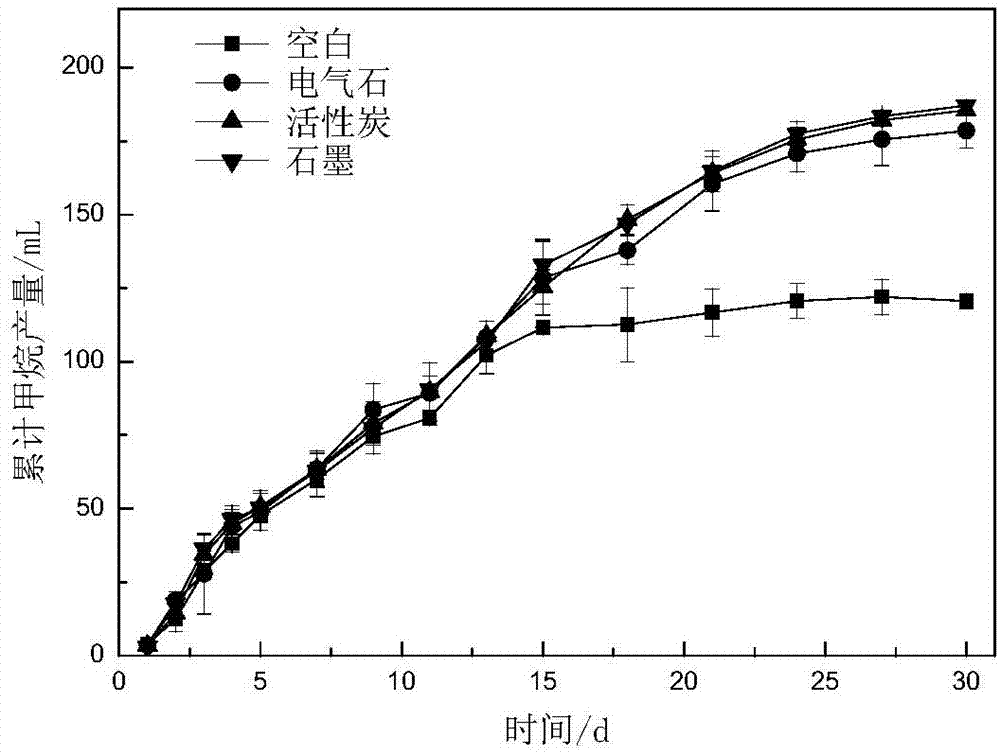

Embodiment 2

[0035]Four groups of 250 mL serum bottles were taken as corn stalk anaerobic reactors, 4 in each group, and the actual reaction volume was 200 mL. Corn stalks, anaerobic inoculation sludge, buffer salt, trace element aqueous solution, and vitamin aqueous solution were added to the serum bottles, so that The initial concentration of corn stalks in the serum bottle was 5g VS / L, the initial concentration of anaerobic inoculated sludge was 2g VS / L, the amount of buffer salt, trace element aqueous solution and vitamin aqueous solution was 1mL / L, and then passed through 1mol / L HCl and 1mol / L NaOH solution to adjust the pH of the system to 7;

[0036] The concentration of various substances in the buffer salt is: NH 4 Cl 10mmol / L, KH 2 PO 4 1mmol / L, MgCl 2 0.5mmol / L, CaCl 2 0.5mmol / L, NaHCO 3 5mmol / L, 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (Hepes) 10mmol / L.

[0037] The concentration of various substances in the trace element aqueous solution is: FeCl 2 10mmol / L, C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com