Device for preparing particulates using supercritical fluid assistant spray and use thereof

A supercritical fluid and particle manufacturing technology, which is applied in the direction of microsphere preparation, liquid separation into beads and granulation, microcapsule preparation, etc., can solve the problems of non-drug-loaded particle research, particle collection and solvent exclusion, etc. , to achieve the effect of convenient preparation and collection, and reducing particle size changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

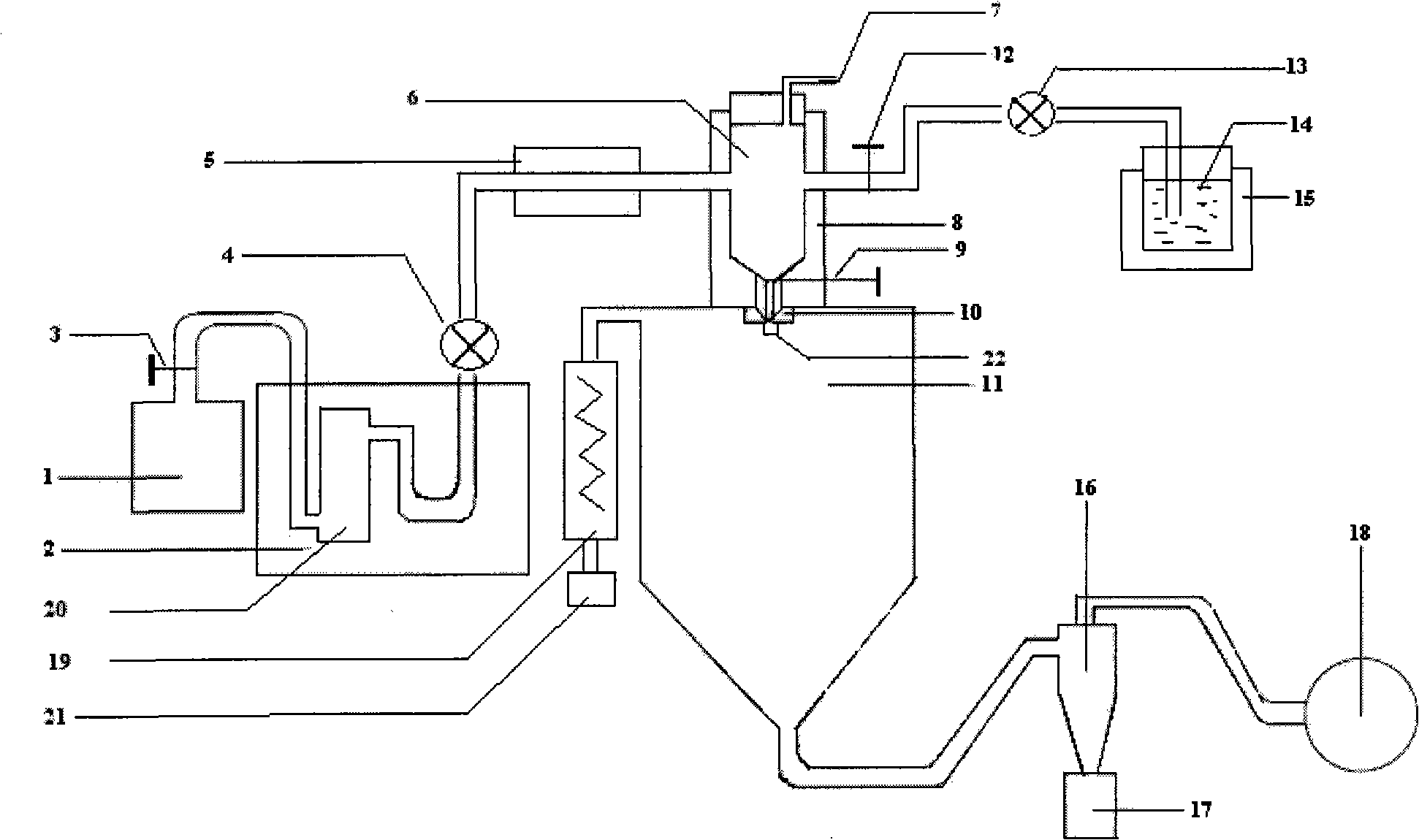

[0016] Embodiment 1: supercritical fluid assisted spray manufacture particle equipment

[0017] see figure 1 , the supercritical fluid assisted spray production particle equipment consists of carbon dioxide storage tank 1, cooling water tank 2, valve 3, plunger pump 4, heater 5, gas-liquid mixing chamber 6, pressure monitoring 7, heating jacket 8, valve 9, nozzle base Seat 10, Drying Box 11, Valve 12, Constant Flow Pump 13, Solvent Storage Tank 14, Heating Mantle 15, Cyclone Separator 16, Collection Tank 17, Air Extractor 18, Air Heater 19, Supercritical Carbon Dioxide Storage Tank 20 , Air filter 21 and nozzle 22.

[0018] The carbon dioxide steel cylinder 1, the valve 3, the supercritical carbon dioxide storage tank 20, the plunger pump 4, and the gas-liquid mixing chamber 6 are connected by threads through pipelines, and the supercritical carbon dioxide storage tank 20 is placed in the cooling water tank 2, and the plunger pump 4 Part of the pipeline between the gas-liqui...

Embodiment 2

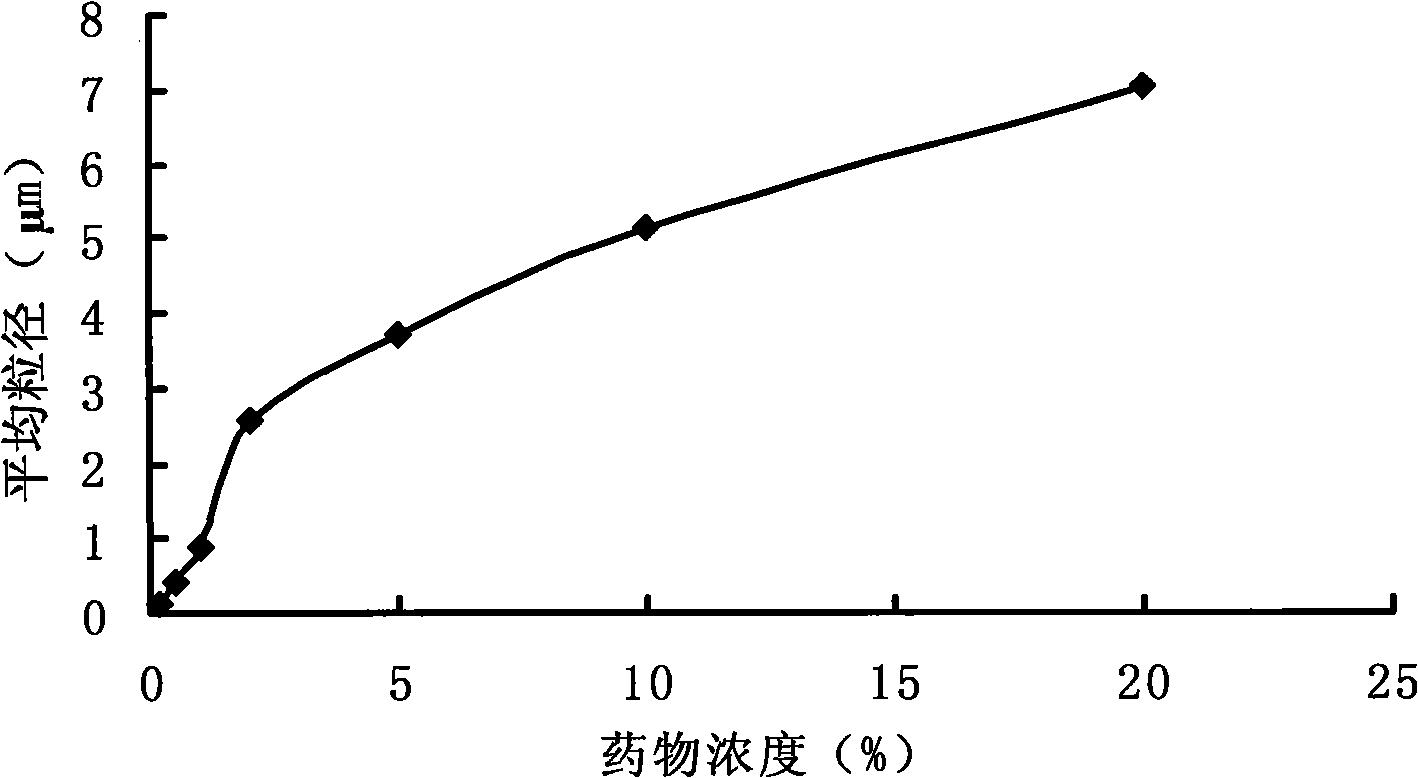

[0020] Example 2: Preparation of drug particles using supercritical fluid-assisted spray manufacturing particle equipment

[0021] Open exhaust fan 18, introduce air or nitrogen from air heater 19, form clean hot air (nitrogen) through filtration and heating, enter drying box 11, control the air inlet temperature of drying box 11 to be 80 ℃, weigh the drug Ni Modipine 1g, dissolved in 100ml of absolute ethanol, was added to the solvent storage tank 14, and the heating temperature of the solvent storage tank 14 was adjusted to 65°C, and was transported to the gas-liquid mixing chamber 6 by a constant flow pump 13 at a flow rate of 10ml / min ; After the liquid carbon dioxide is cooled, it is pressurized by the plunger pump 4, and after being heated to 65°C, it is sent into the gas-liquid mixing chamber 6 preheated to 65°C, and the delivery speed of carbon dioxide is controlled at 30ml / min respectively. When the pressure of the chamber 6 reaches 9Mpa, the valve 9 is opened, and th...

Embodiment 3

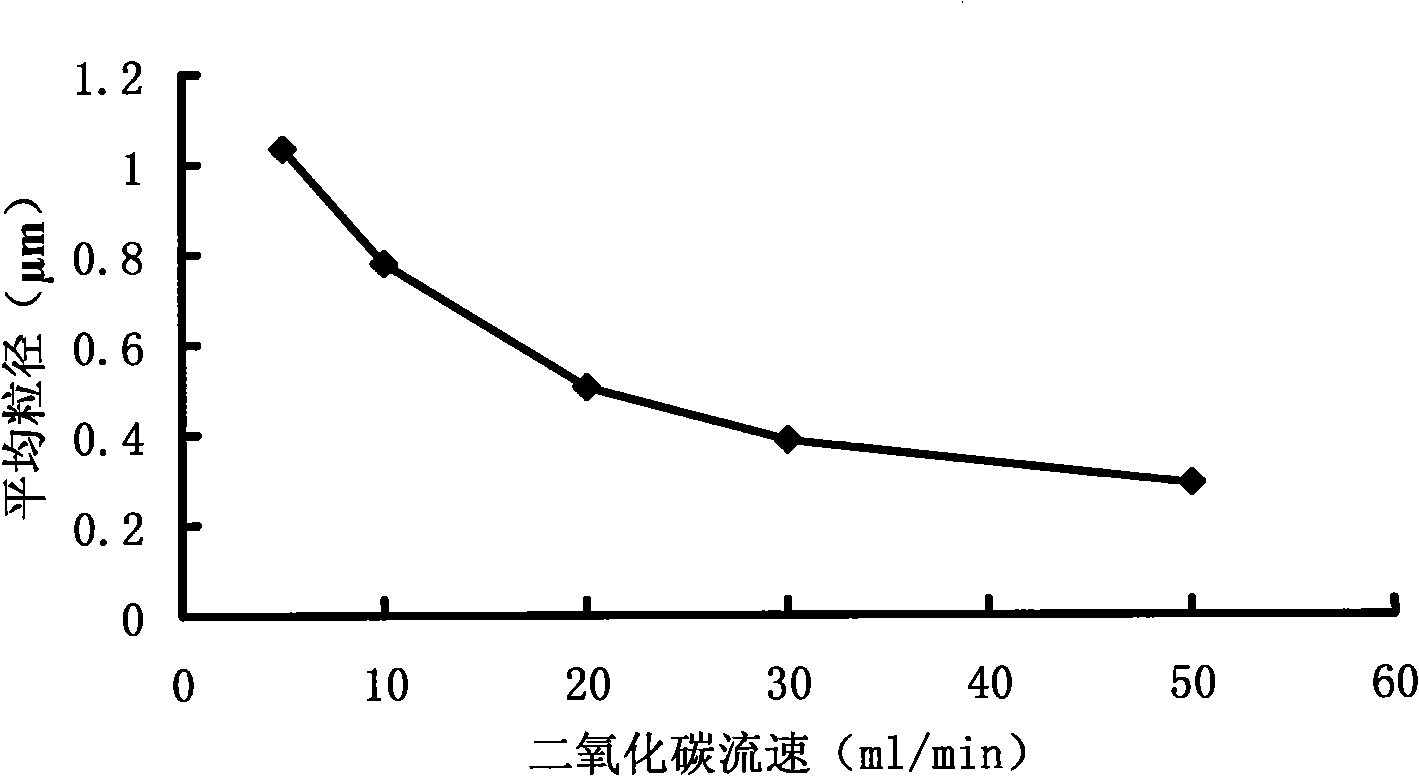

[0024] Example 3: Preparation of drug-loaded particles using supercritical fluid-assisted spray manufacturing particle equipment

[0025] Open the exhaust fan 18, introduce air or nitrogen from the air heater 19, form clean hot air (nitrogen) through filtration and heating, enter the drying oven 11, control the air inlet temperature of the drying oven 11 to be 80 ° C, weigh the stearin Acid 0.5g, dissolved in 100ml of absolute ethanol, added to the solvent storage tank 14, adjust the heating temperature of the solvent storage tank 14 to be 65 ° C, transported to the gas-liquid mixing chamber 6 by the constant flow pump 13, flow rate 10ml / min After the liquid carbon dioxide is cooled, it is pressurized by the plunger pump 4, and after being heated to 65°C, it is sent into the gas-liquid mixing chamber 6 preheated to 65°C, and the delivery speed of the carbon dioxide is controlled at 5, 10, 20, 30, 50ml / min. When the pressure of the gas-liquid mixing chamber 6 reaches 9Mpa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com