Technique for synthesizing methanol by hydrogen and carbon dioxide

A technology for carbon dioxide and methanol synthesis, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of high energy consumption, impurity components, and high temperature changes, and achieves low energy consumption and reaction temperature. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

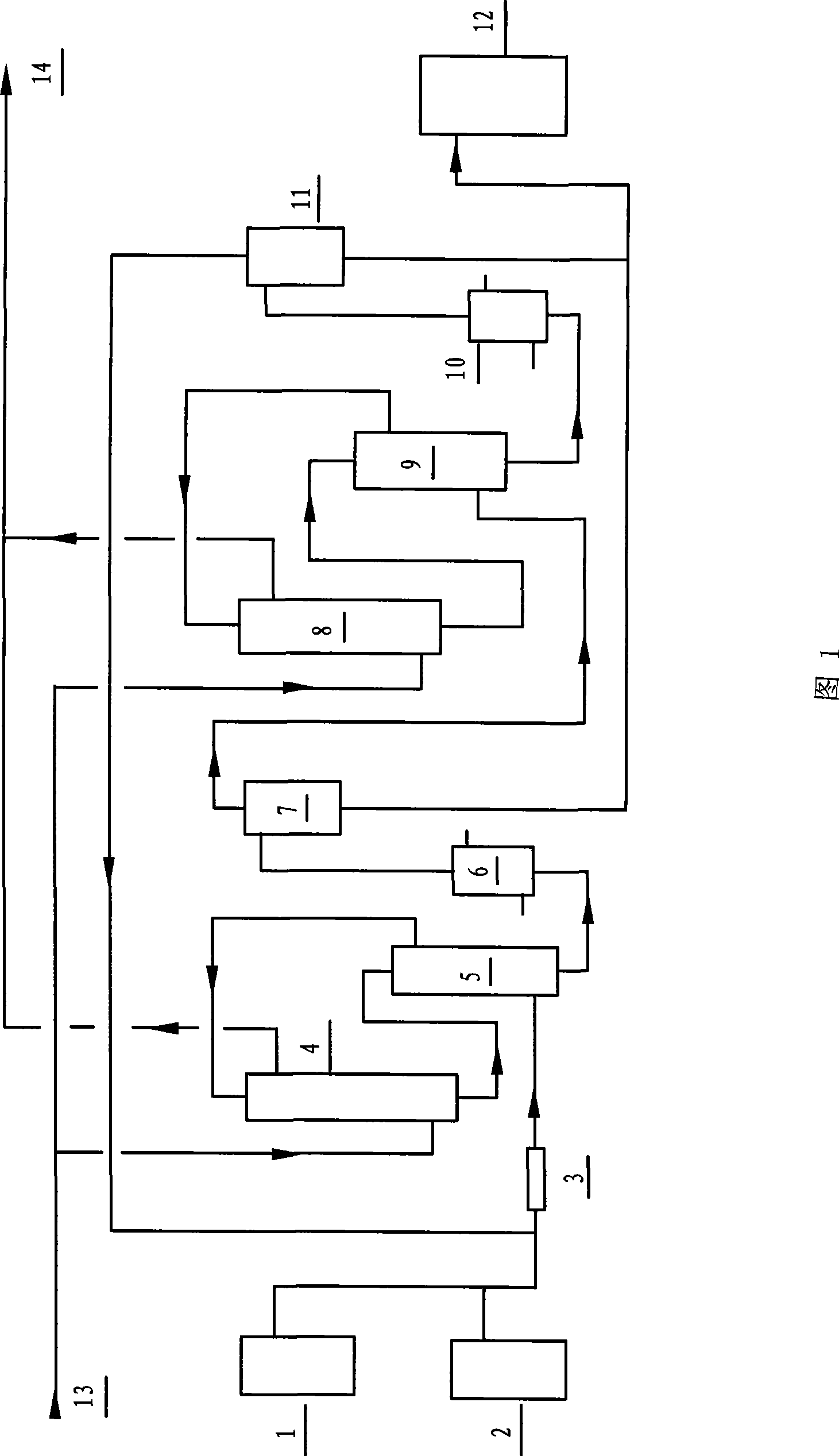

Image

Examples

Embodiment 1

[0029] The processing method of present embodiment hydrogen and carbon dioxide synthesis methanol comprises following major steps:

[0030] (1), the first step of catalytic reaction: hydrogen and carbon dioxide with a volume ratio of 3:1 in 16000h -1 The space velocity is passed into the first reactor, and under the action of a copper-based hydrogenation catalyst with a Cu:Zn:Al molar ratio of 63:25:12, at a temperature of 230°C and a pressure of 8.5Mpa, the first step of catalytic hydrogenation is carried out Reaction to obtain methanol, water, carbon monoxide;

[0031] In this step, 5.9% of the carbon dioxide is converted into carbon monoxide and water, and 16.3% of the carbon dioxide is converted into methanol and water;

[0032] (2), gas-liquid separation: methanol, water, carbon monoxide and unreacted hydrogen and carbon dioxide after the above-mentioned (1) step reaction are carried out gas-liquid separation, methanol and water in the liquid state are separated as produ...

Embodiment 2

[0036] The processing method of present embodiment hydrogen and carbon dioxide synthesis methanol comprises following major steps:

[0037] (1), the first step of catalytic reaction: hydrogen and carbon dioxide with a volume ratio of 3:1 in 10000h -1 The space velocity is passed into the first reactor, and under the action of a copper-based hydrogenation catalyst with a Cu:Zn:Al molar ratio of 65:23:12, at a temperature of 250°C and a pressure of 5.5Mpa, the first step of catalytic hydrogenation is carried out Reaction to obtain methanol, water, carbon monoxide;

[0038] In this step, 8.6% of carbon dioxide is converted into carbon monoxide and water, and 16.6% of carbon dioxide is converted into methanol and water;

[0039] (2), gas-liquid separation: Carry out gas-liquid separation of methanol, water, carbon monoxide and unreacted hydrogen and carbon dioxide after the above-mentioned (1) step reaction, and methanol and water in liquid state are separated as product solution...

Embodiment 3

[0043] The processing method of present embodiment hydrogen and carbon dioxide synthesis methanol comprises following major steps:

[0044] (1), the first step of catalytic reaction: hydrogen and carbon dioxide with a volume ratio of 3:1 in 5000h -1 The space velocity is passed into the first reactor, and under the action of the copper-based hydrogenation catalyst under the action of the copper-based hydrogenation catalyst with a Cu: Zn: Al molar ratio of 70: 18: 12, the temperature is 280 ° C and the pressure is 8.0 Mpa. Carry out the first step of catalytic hydrogenation reaction to obtain methanol, water and carbon monoxide;

[0045] In this step, 13.0% of the carbon dioxide is converted into carbon monoxide and water, and 21.5% of the carbon dioxide is converted into methanol and water;

[0046] (2), gas-liquid separation: methanol, water, carbon monoxide and unreacted hydrogen and carbon dioxide after the above-mentioned (1) step reaction are carried out gas-liquid separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com