Process for simultaneous production of carbon disulfide, sulfur and insoluble sulfur

A technology of carbon disulfide and sulfur, which is applied in the direction of carbon disulfide, sulfur compounds, carbon sulfur compounds, etc., to achieve the effects of process simplification, secondary tax and transportation costs, and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

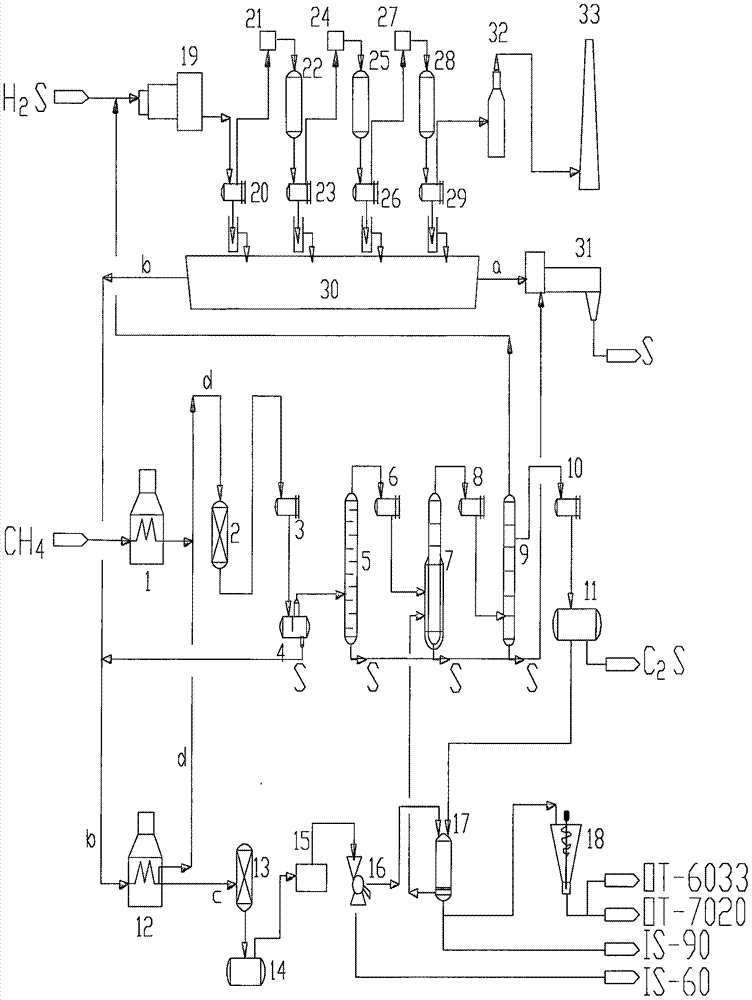

[0030] Embodiment 1, see accompanying drawing:

[0031] Sulfur recovery unit: acid gas from petrochemical enterprises or carbon disulfide units at 40°C, 0.15MPa, according to 2H 2 S+O 2 =2S+2H 2 O, 2H 2 S+3O 2 =2SO 2 +2H 2 O, 2H 2 S+SO 2 =2S+2H 2O Reaction equation gas distribution, sent to the Claus furnace 19, 19 behind the Claus furnace contains a waste heat boiler, the temperature of the Claus furnace is raised to 1100-1300 ° C, preferably 1200 ° C to react, the gasified sulfur and the mixture The gas product is cooled to 400-450°C after being heated by the waste heat boiler, 400°C is selected, and sent to the condenser 20, the temperature is cooled to 160-170°C, and 165°C is selected, and the liquid sulfur captured by the sulfur trap enters Liquid sulfur tank 30, process gas goes to heater 21, goes to converter 22 after heating, through condenser 23, the sulfur of catcher is sent into liquid sulfur tank 30, carried out four-stage cooling 20, 23, 26, 29, three-st...

Embodiment 2

[0034] Embodiment 2, see accompanying drawing:

[0035] Sulfur recovery unit: acid gas from petrochemical enterprises or carbon disulfide units at 40°C, 0.15MPa, according to 2H 2 S+O 2 =2S+2H 2 O, 2H 2 S+3O 2 =2SO 2 +2H 2 O, 2H 2 S+SO 2 =2S+2H 2 O Reaction equation gas distribution, send it to Claus furnace 19, heat up 1100-1300°C, choose 1300°C for reaction, the generated gasified sulfur and mixed gas products are cooled to 400-450°C by waste heat boiler, choose 430°C, send Enter the condenser 20, the temperature is cooled to 170-170 ° C, choose 170 ° C, the liquid sulfur captured by the sulfur trap enters the liquid sulfur tank 30, the unreacted gas goes to the heater 21, and after heating, it goes to the converter 22 , through the condenser 23, the sulfur of the catcher is sent to the liquid sulfur tank 30, and four-stage cooling 20, 23, 26, 29, 21, 24, 27, and three-stage conversion 22, 25, 28 are carried out by this method , the collected liquid sulfur enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com