Method for selectively desorbing carbon disulfide in coarse benzene

A carbon disulfide and selective technology, applied in the field of coal chemical industry, can solve the problems of non-recyclable carbon disulfide, high energy consumption, cumbersome process, etc., and achieve the effects of high selective adsorption and removal rate, mild adsorption operation conditions, and simplified operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Removal of carbon disulfide:

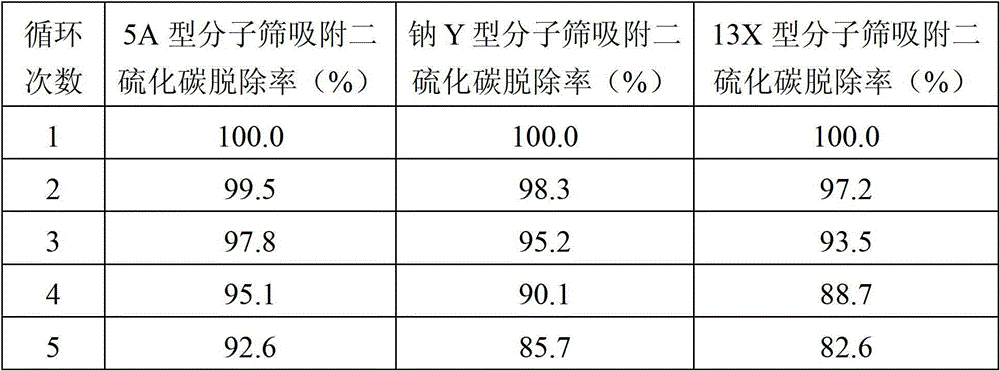

[0018] Dissolve carbon disulfide in pure benzene to make simulated crude benzene, so that the concentration of carbon disulfide in simulated crude benzene is 3000mg / kg. 200g of 5A-type silica-alumina molecular sieve (Nankai University Catalyst Factory) was fixed in the adsorber, under normal temperature and pressure, the space velocity ratio was 0.7h -1 , into simulated crude benzene, the reaction result is that the adsorption and removal rate of carbon disulfide is 100%.

[0019] Recovery of carbon disulfide:

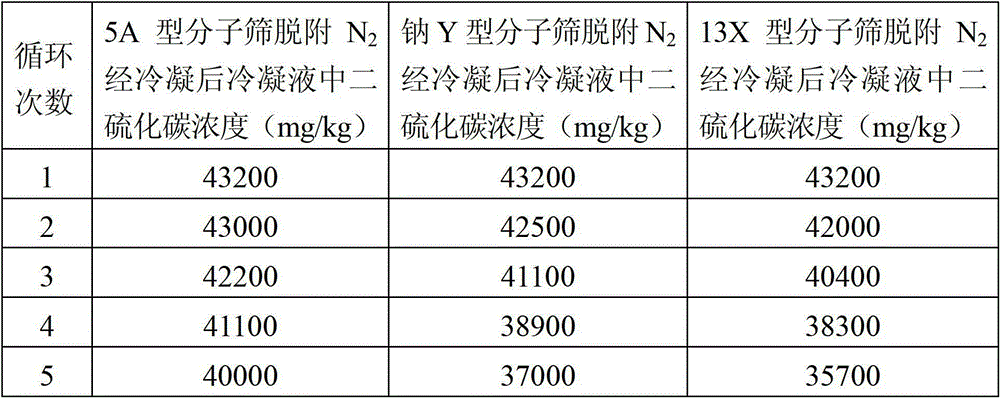

[0020] After the 5A-type silica-alumina molecular sieve adsorbent is saturated, the N 2 Purge, heat up to 300°C within 2 hours, maintain 300°C for 3 hours to purify for the first regeneration, and record the 5A-type silica-alumina molecular sieve after the first regeneration as sample I. N after purge 2 After being condensed by the condenser, the carbon disulfide in it is condensed and recovered, and the condensate is recorded ...

Embodiment 2

[0023] Removal of carbon disulfide:

[0024] Dissolve carbon disulfide in pure benzene to make simulated crude benzene, so that the concentration of carbon disulfide in simulated crude benzene is 3000mg / kg. Fix 200g of sodium Y-type silica-alumina molecular sieve (Nankai University Catalyst Factory) in the adsorber, under normal temperature and pressure, the space velocity ratio is 0.7h -1 , into simulated crude benzene, the reaction result is that the adsorption and removal rate of carbon disulfide is 100%.

[0025] Recovery of carbon disulfide:

[0026] After the sodium Y-type silica-alumina molecular sieve adsorbent is saturated, N 2 Purge, heat up to 300°C within 2 hours, maintain 300°C for 3 hours to purify for the first regeneration, and record the sodium Y-type silica-alumina molecular sieve after the first regeneration as sample III. N after purge 2 After being condensed by the condenser, the carbon disulfide in it is condensed and recovered, and the condensate is ...

Embodiment 3

[0029] Removal of carbon disulfide:

[0030] Dissolve carbon disulfide in pure benzene to make simulated crude benzene, so that the concentration of carbon disulfide in simulated crude benzene is 3000mg / kg. 200g of 13X type 13X silica-alumina molecular sieve (Nankai University Catalyst Factory) was fixed in the adsorber, under normal temperature and pressure, the space velocity ratio was 0.7h -1 , into simulated crude benzene, the reaction result is that the adsorption and removal rate of carbon disulfide is 100%.

[0031] Recovery of carbon disulfide:

[0032] After the 13X-type silica-alumina molecular sieve adsorbent is saturated, N 2 Purge, heat up to 300°C within 2 hours, maintain 300°C for 3 hours to purify for the first regeneration, and record the 13X-type silica-alumina molecular sieve after the first regeneration as sample VI. N after purge 2 After being condensed by the condenser, the carbon disulfide in it is condensed and recovered, and the condensate is recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com